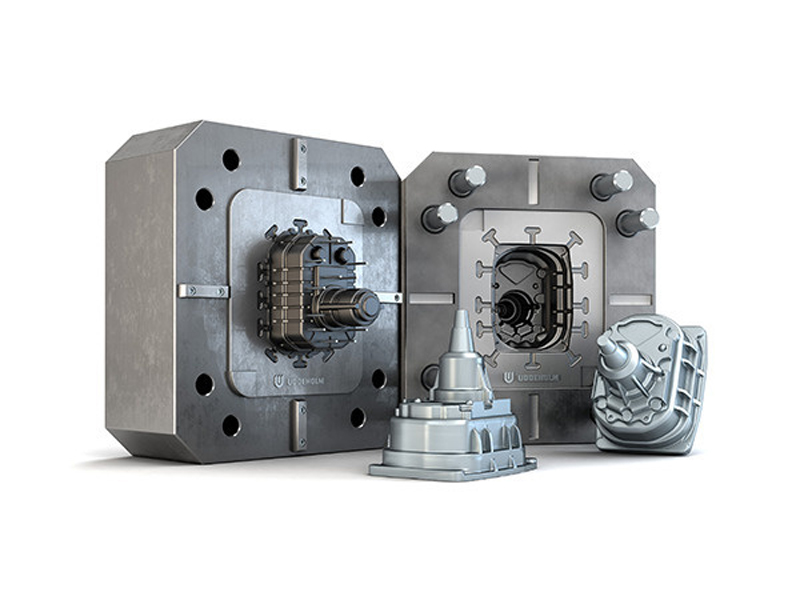

What is Die Casting Tooling

Die casting tooling is the process of creating metal parts by injecting molten metal into a mold. The mold is usually made of steel or aluminum and can be reused many times. The molten metal is usually injected under high pressure, which helps to create parts with a smooth surface finish.

1000+ Die Casting Tooling Manufacturing Experience

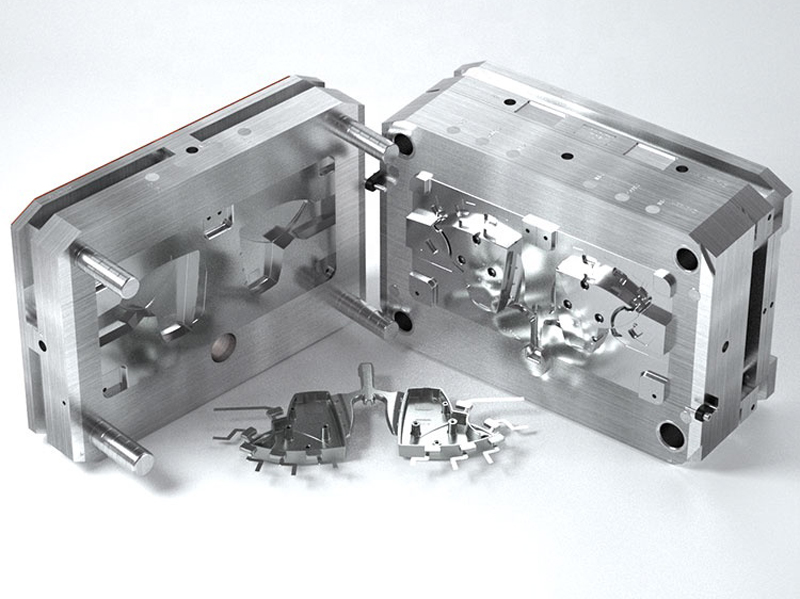

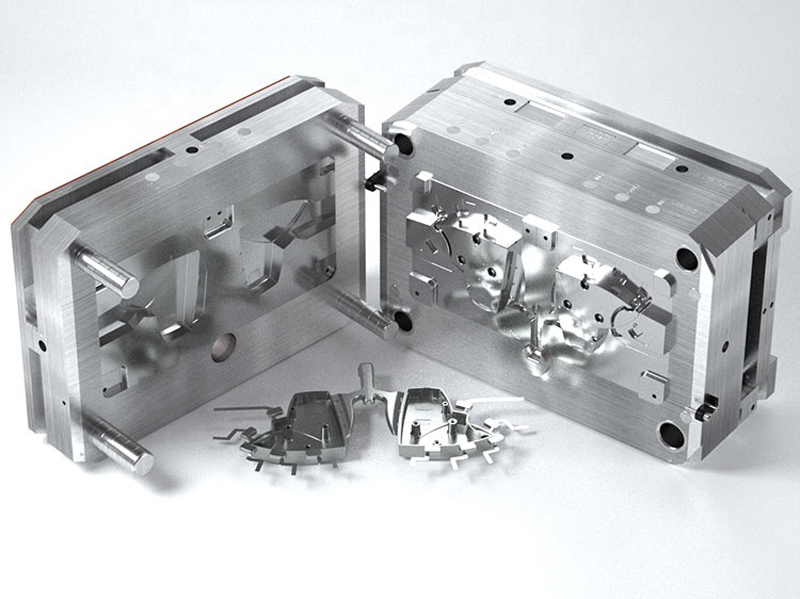

Die Casting Tooling for Automotive Industrial Project

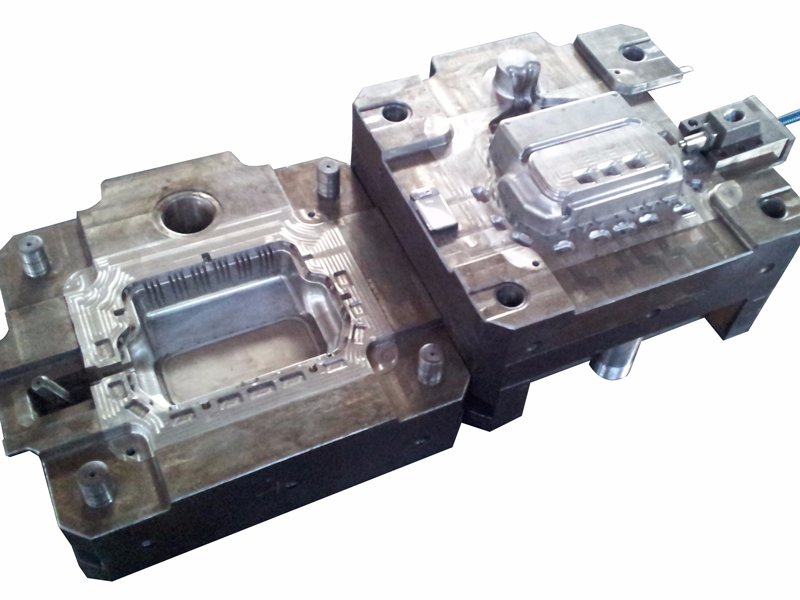

Die Casting Tooling for General Industrial Project

Die Casting Tooling for General Industrial Project

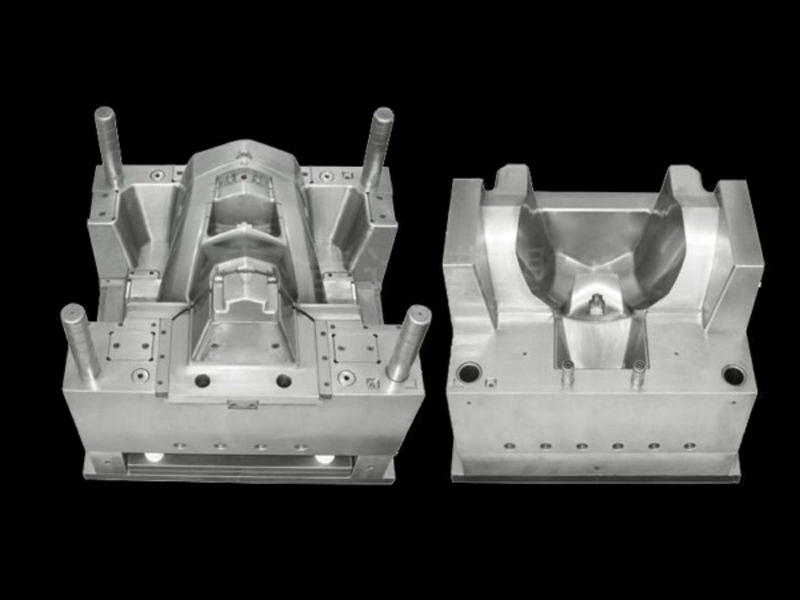

Die Casting Tooling for Household Project

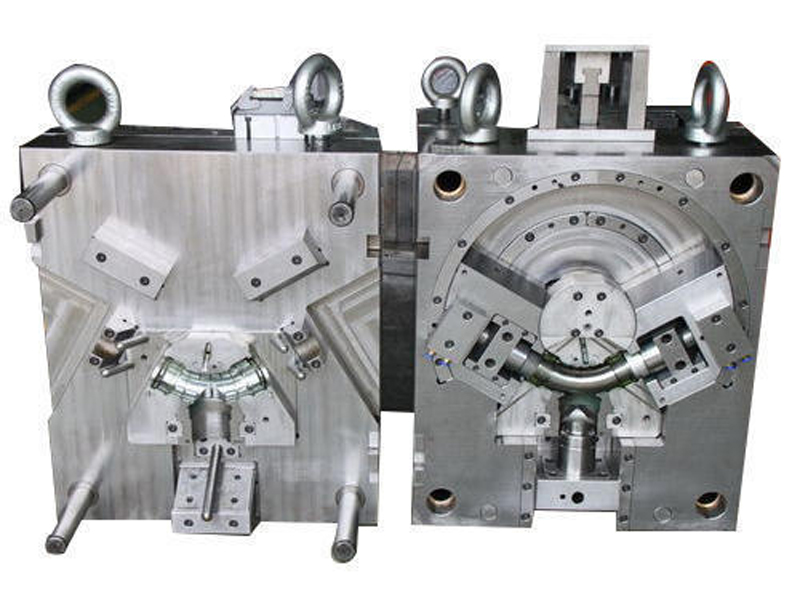

Die Casting Tooling for Marine Industrial Project

Die Casting Tooling for Medical Industrial Project

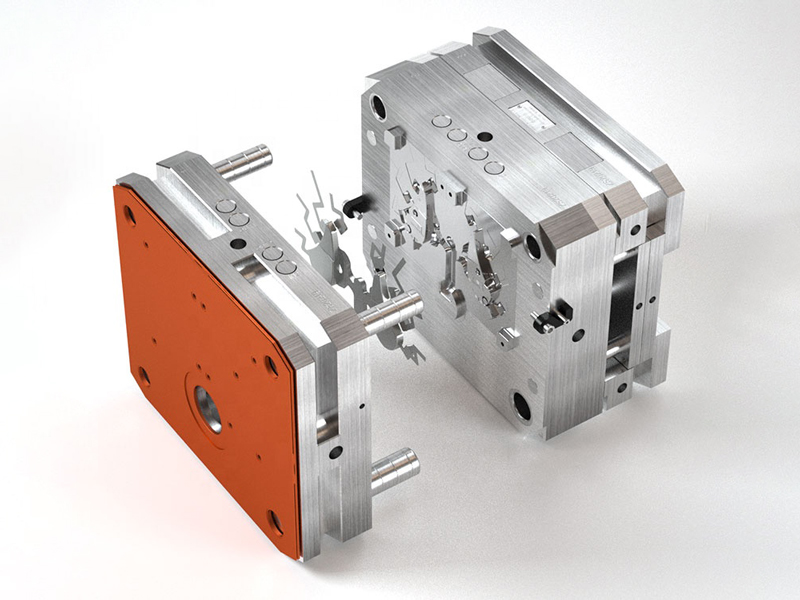

Die Casting Tooling for Telecom Industrial Project

Die Casting Tooling for Telecom Industrial Project

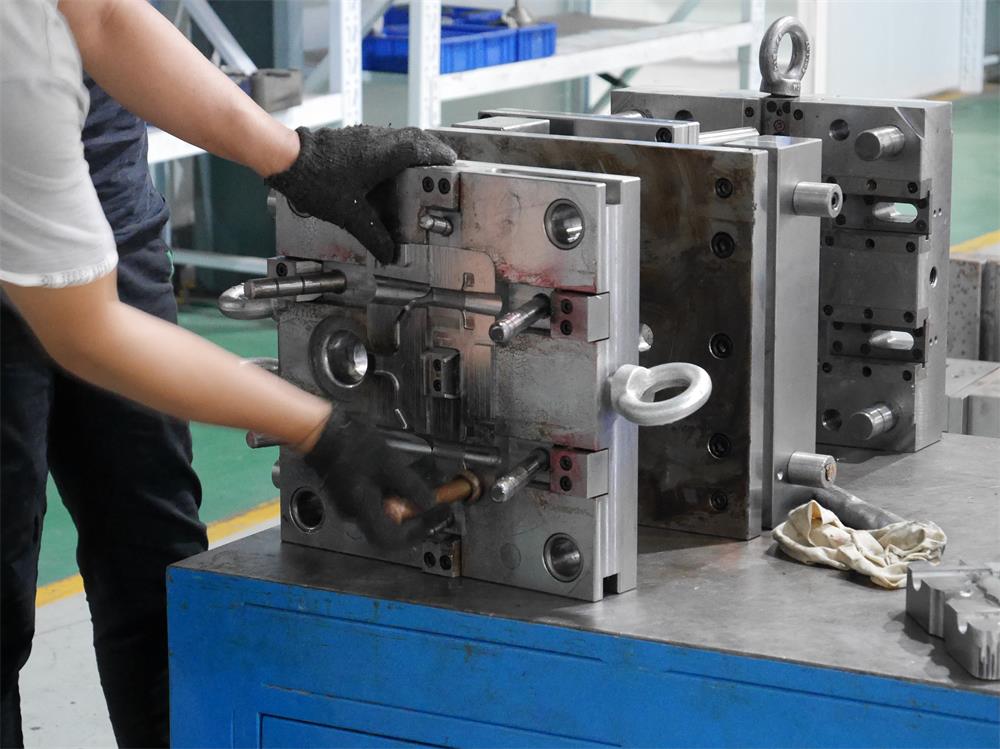

Competent Die Casting Tooling Capability To Fulfill

Your Aluminum Die Casting Project

In house aluminum die casting tooling shop to meet variable project demands without any delays.Send us your detailed aluminum die casting tooling request now !

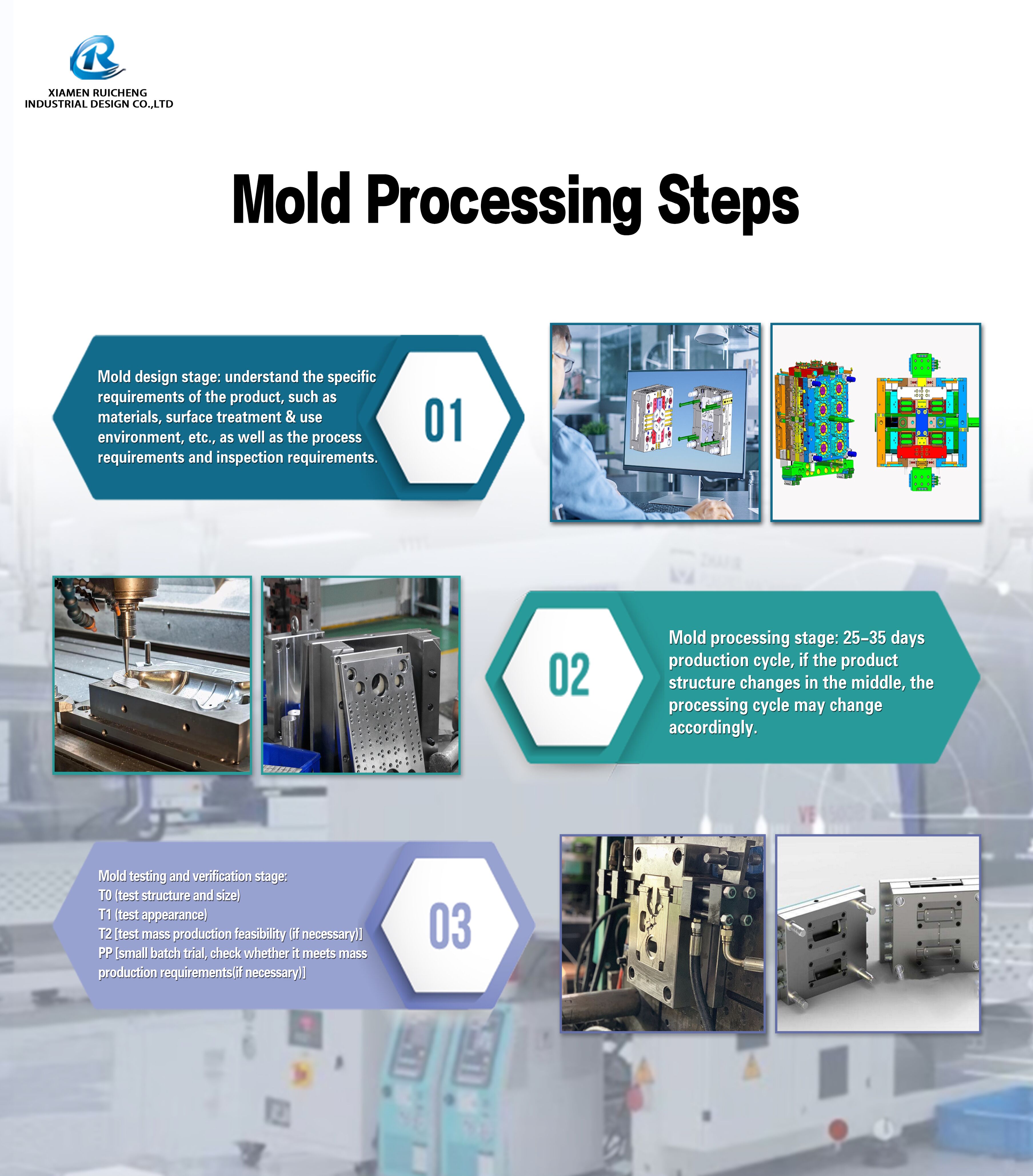

● Mold design stage: understand the specific requirements of the product, such as materials, surface treatment & use environment, etc., as well as the process requirements and inspection requirements.

● Mold processing stage: 25-35 days production cycle, if the product structure changes in the middle, the processing cycle may change accordingly.

● Mold testing and verification stage:

√ T0 (test structure and size)

√ T1 (test appearance)

√ T2 [test mass production feasibility ]

√ PP [small batch trial, check whether it meets mass production requirements]

High Quality Die Casting Tooling Supported By High-Tech

Process Machines at Xiamen Ruicheng

Mold Machining Equipment

Mold Machining Equipment

Mold Machining Equipment

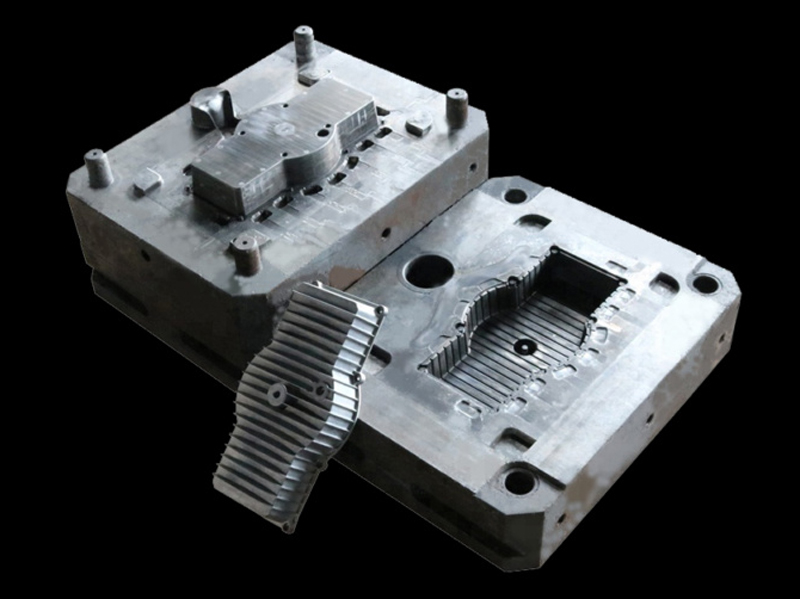

Recent Die Casting Tooling Projects

Ultrasmooth die casting tooling designs and manufacturing processes are at the centre of Xiamen Ruicheng Metal’s commitment. Currently, we are engaged in various projects with long-standing clients:

Automotive Housing by Aluminum Die Casting Tooling

Construction Bracket by Aluminum Die Casting Tooling

Fishing Tool by Aluminum Die Casting Tooling

Heat Sink by Aluminum Die Casting Tooling

Marine Bracket by Aluminum Die Casting Tooling

Radar Cover by Aluminum Die Casting Tooling

How Is The Cast Part Removed From

The Aluminum Die Casting Tooling?

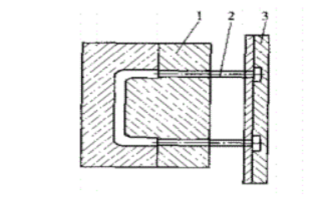

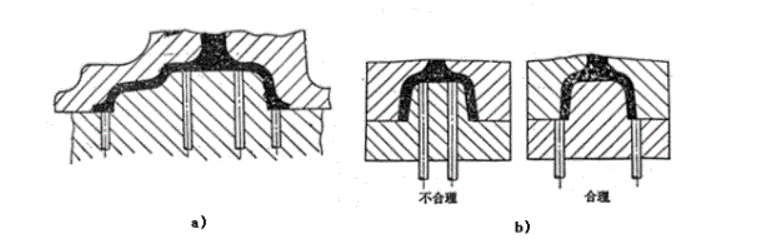

Die castings are designed to leave the casting on the base as much as possible, and no other mechanism is required to remove the casting. However, some castings left in the base is also difficult to remove the type, the need to use the ejector casting mechanism. As shown in the figure below, the casting can be ejected. In the design of the ejector casting, according to the shape of the casting design should pay attention to the following points.

Figure 1: 1-Metal Part 2-Top Bar 3-Top Bar Plate

①To avoid deforming the casting item when ejecting the casting. The top bar should be evenly arranged and at the place with the greatest resistance to the exit, as shown in Figure 2

Figure 2: top bar plate design

②In order to avoid leaving deep top ejector bar marks on the casting, the contact area between the top bar and the casting should be large enough, in addition to increasing the number of top bars. The top bar should be placed on the gate as much as possible.

③To prevent the top bar from jamming, the gap between the top bar and the top bar hole should be appropriate. If the gap is too large, it is easy to drill into the metal.

Get A Free Consultation Now

If you have any questions on your die casting tooling projects or you are looking for a China aluminum die casting manufacturer, you are welcome to contact Xiamen Ruicheng to learn more. Our experienced engineering team consults for your die casting mold projects with skillful suggestions and solutions based on your CAD and Step drawings.