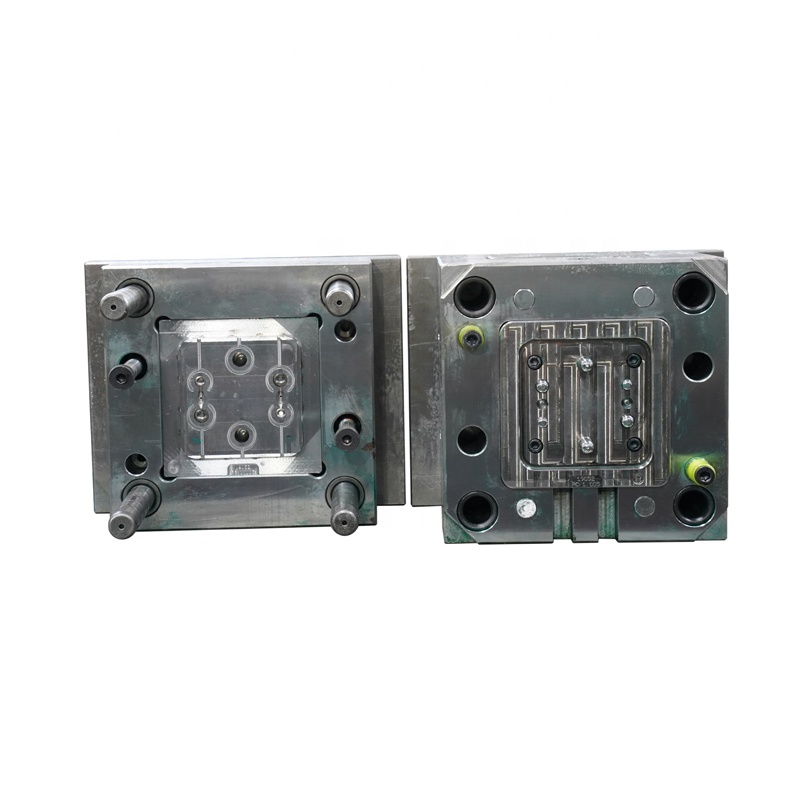

mould for silicone production

rubber compression tooling

silicone compression mould

silicone rubber mould

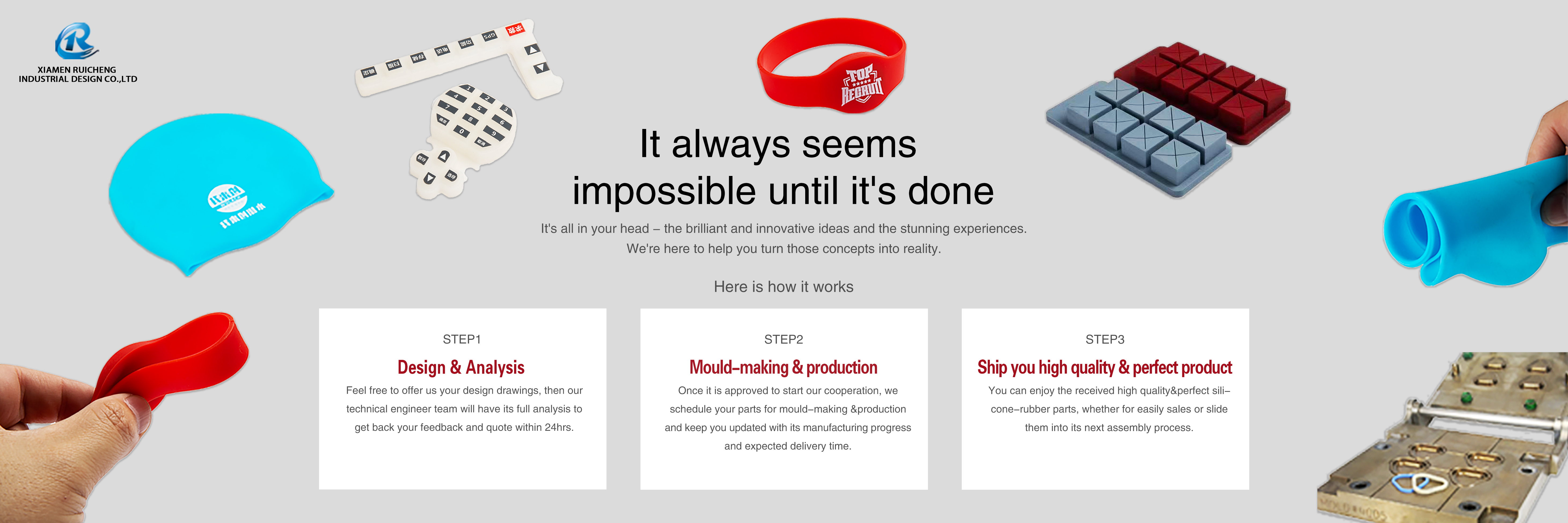

Silicone Rubber Molds Capabilities & Application Used Cmmonly

※Phone holder & cover

※Tablet PC cover

※Overmolding USB disk cover & case

※Ladle cover

※Cup & Cup Cap

※Keypad

※Shovel,spade, scoop & spatula

※Gasket,bracelet & wallet

※Barrel ,Brush & Plug

※Automotive key case

※Ice cream & Chocolate mold

※Bottle sleeve

Won’t Let You Down Our Silicone Rubber Expertise

More than 20 years working on a diverse range of projects has taught us that there is no such thing as a one-size-fits-all manufacturing methodology.

Our silicone rubber engineers will take the time to understand your needs, find or develop the right part with suitable material/mould-making method to ensure your projects can be successfully manufactured and launched then to last our relationships.

Added Value to Meet Your Every Need

The extensive expertise of Xiamen Ruicheng’s production and engineering personnel has made our Value-Added Operations(include Screen Printing, Testing, Special Packaging, Bar Coding, Pressure Sensitive Adhesives, Mold Texturing and/or engraving, Complete Sub-Assemblies and more) a fast growth . To offer you high-quality, value added components that are delivered on time, we leverage life and work experiences and training within our New Product Development Processes guided by our ISO-quality system which is utilizing all our extensive capabilities.

Since the manufacturing and tooling of stage the most costly stage, with initial tooling setup costs, product testing, standardization etc. We don’t take a “one size fits all” approach.