Styrene injection molded parts are widely used in vibration damping and noise reduction due to their excellent damping properties. This material’s unique structure can effectively absorb and disperse vibrations, reducing noise pollution and enhancing product performance.

As the market increasingly demands noise reduction and comfort, the application of styrene injection molded parts has grown and become an essential choice in many industries.

How Do Damping Properties Affect Noise Control?

Styrene injection molded parts effectively reduce vibrations and noise through their unique damping properties. They absorb energy during vibration transmission, thus reducing the generation of noise. As modern industry increasingly demands noise control, the application of styrene materials has become crucial.

- Soundproofing: Reduces sound propagation, lowering environmental noise.

- Vibration Absorption: Learn more about vibration absorption technology.

- Durability: Enhances the material’s impact resistance, improving service life.

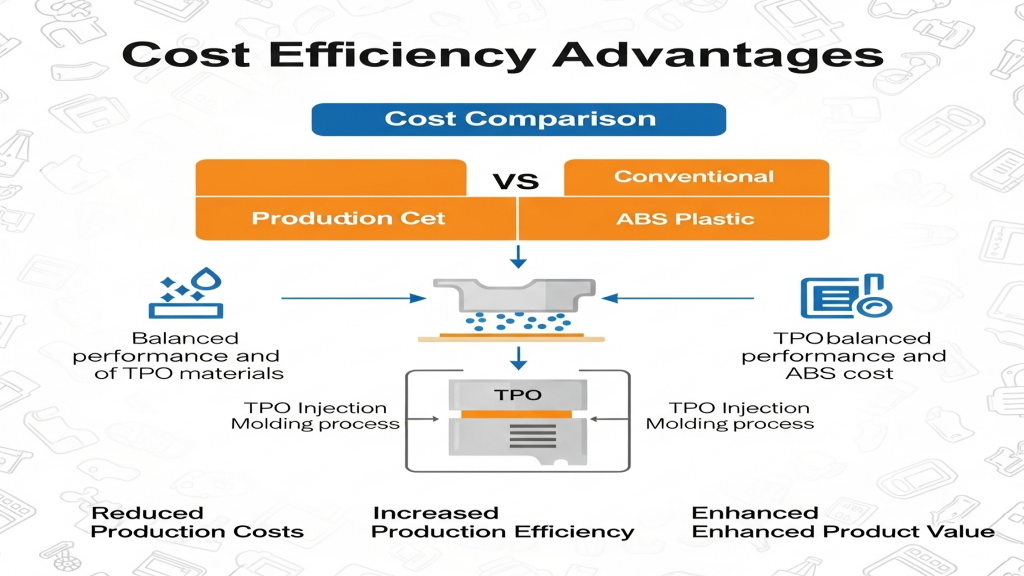

- Cost-Effectiveness: Explore the balance between cost-effectiveness and performance

What Industries Benefit from Styrene Injection Molding?

Styrene injection molded parts, with their unique properties, are applied in multiple industries, including automotive, electronics, and construction. These industries face noise pollution and vibration interference, and styrene materials effectively solve these problems. With advancements in technology, the application of styrene injection molded parts continues to expand.

- Automotive Industry: Effectively isolates noise generated by engines and bodies.

- Electronics: See applications in electronic devices.

- Construction: Reduces noise transmission in and out of buildings.

- Home Appliances: Enhances product comfort and user experience.

How Does Damping Improve User Experience?

Styrene injection molded parts significantly enhance the comfort and quietness of products through their excellent damping performance. Their high energy absorption characteristics make products more stable during use, reducing unnecessary vibrations and noise. This effect, especially in products used daily by consumers, enhances the user experience.

- Improved Comfort: Makes devices operate more smoothly.

- Noise Reduction: Learn more about noise reduction technology.

- Improved Handling: Reduces the impact of mechanical vibrations on handling.

- Enhanced Brand Value: Increases consumer recognition of the brand.

Damping Comparison

|

Feature |

Styrene Molding |

Rubber |

Polyurethane |

Polycarbonate |

| Damping Effect | Strong | Medium | Strong | Weak |

| Service Life | Long | Medium | Long | Short |

| Environmental | High | Low | Medium | High |

| Cost | Medium | Low | High | Medium |

Wide Range of Applications

Styrene injection molded parts, with their excellent damping properties, have become the go-to material for noise reduction and vibration damping in various industries. This material has been widely applied in automotive and electronics industries, as well as other fields, showing its unique properties. As technology advances, styrene injection molded parts will continue to play a key role in more application scenarios.

1.Wide Applications: Styrene injection molded parts are applied across multiple industries.

2.Excellent Performance: The material has strong damping properties and durability.

3.Enhanced Comfort: Provides a more comfortable user experience.

4.Noise Reduction: Effectively reduces noise and vibration transmission.

Conclusion

Styrene injection molded parts, with their unique damping properties, have become the ideal choice for solving noise pollution and vibration problems in many industries. This material has shown significant effects in multiple fields and offers long-term stable performance advantages. With technological advancements, it will continue to provide more solutions for industrial production and consumer products in the future.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-10-2025