Introduction

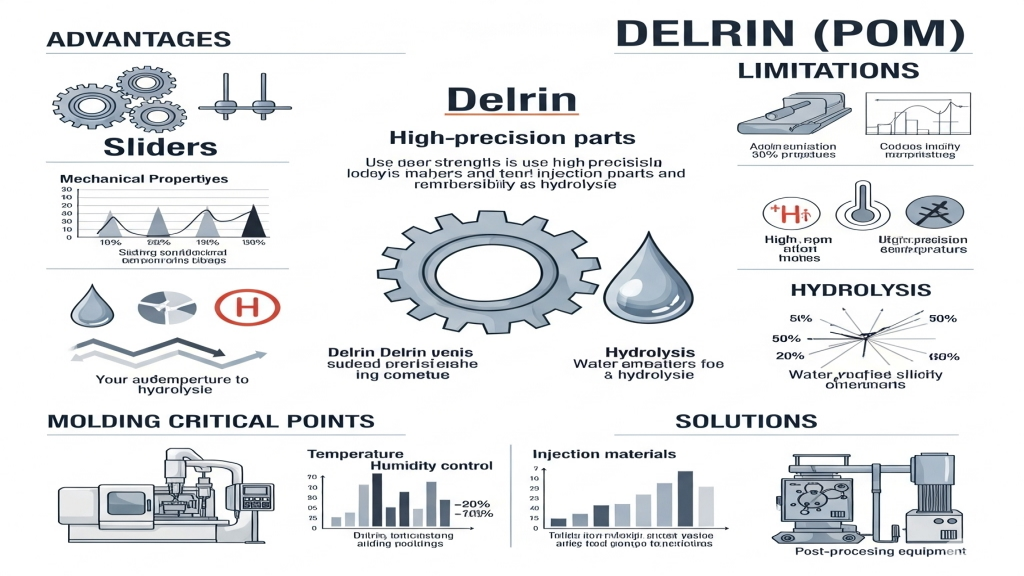

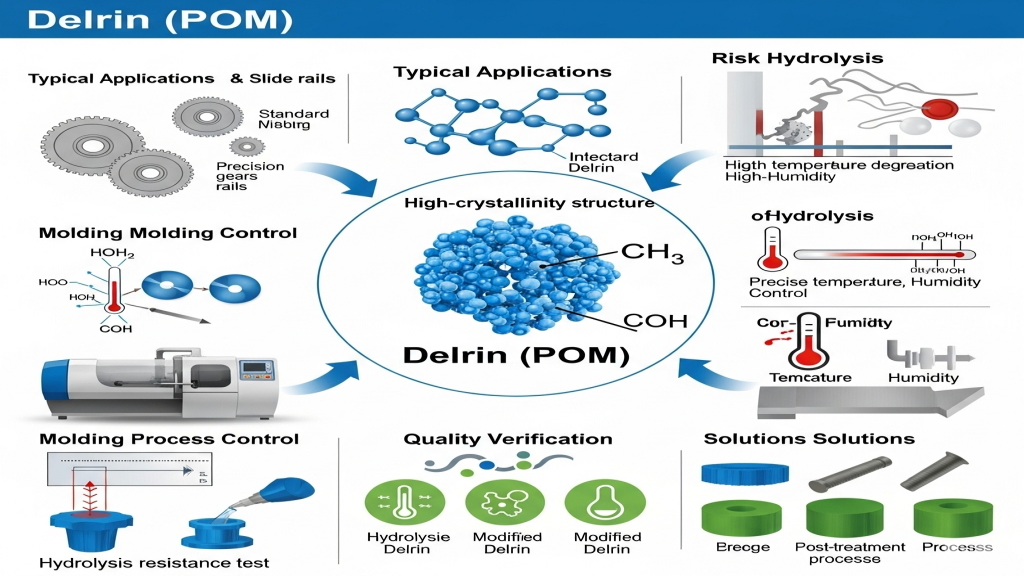

Delrin is a high-crystallinity POM material widely used in high-precision injection molded parts due to its excellent mechanical properties and dimensional stability. It is especially favored for components like gears and slides because of its superior dry friction performance.However, under high-temperature and high-humidity conditions, its hydrolysis resistance becomes a critical limitation.

From a molding perspective, Delrin is particularly sensitive to molding temperature and residual moisture. Without proper control, molecular degradation can occur rapidly. Manufacturers must validate its hydrolysis resistance boundary before mass production to ensure long-term reliability.Especially in hot and humid conditions, its durability depends on modification and post-treatment.

How does Delrin perform under elevated temperatures?

Under sustained heat, Delrin’s molecular structure absorbs moisture and accelerates hydrolysis, significantly reducing mechanical strength. Different Delrin grades exhibit varied thermal resistance, making environment-based grade selection crucial.Hydrolytic micro-chain scission is the primary failure mechanism.

- Heat resistance comparison: Clear performance difference between Delrin 500P and 900P

- Failure curve data: Continuous exposure above 90°C accelerates degradation

- Processing temperature control: Avoid decomposition by setting optimal melt temperatures

- Thermo-oxidative effects: Oxygen accelerates hydrolysis, requiring careful design precautions

Delrin quickly enters the hydrolysis risk zone when exposed to heat and moisture.

Why does Delrin fail more easily in humid environments?

Delrin’s molecular end groups are sensitive to moisture, especially under humid or hot water conditions where water penetrates through microcracks and causes chain breakage. This structural degradation is usually irreversible and tends to surface in later product life cycles.Moisture-induced degradation is particularly prominent in tropical or outdoor environments.

- Moisture absorption data: Equilibrium moisture absorption for Delrin is 0.2%-0.3%

- Failure case studies: Strength drops sharply in humidity chambers

- Water-resistant design: Overmolding can help slow vapor ingress

- Scheduled replacement: Component cycling may be required in long-term humid use

In humid conditions, Delrin faces structural failure risks that require design mitigation.

What factors during molding affect Delrin’s hydrolysis resistance?

During injection molding, excessive melt temperatures or residual mold moisture can trigger hydrolysis risks. Improperly dried molds or high mold temperatures can cause Delrin to degrade, smoke, or even burn.Process control is essential to ensure stable hydrolysis performance.

- Pre-drying protocol: Moisture content must be below 0.2% before molding

- Melt temperature control: Recommended not to exceed 215°C to avoid thermal degradation

- Vent design in molds: Proper venting reduces accumulation of volatiles

- Cycle time setting: Overlong hold pressure increases shear heat

Proper process tuning is key to stable Delrin injection performance.

Comparative Hydrolysis Resistance of Different Delrin Grades

|

Grade |

Hot Water Resistance |

Moisture Absorption (%) |

Continuous Use Temp (°C) |

Drying Recommendation |

Hydrolysis Rating |

Typical Application |

Modifiable |

| Delrin 500P | Moderate | 0.20 | 90 | 80°C / 4h | ★★☆☆☆ | Slide Blocks | Yes |

| Delrin 900P | High | 0.25 | 100 | 80°C / 4h | ★★★☆☆ | Gears | Yes |

| Delrin AF | Higher | 0.18 | 120 | 90°C / 6h | ★★★★☆ | Wear Parts | No |

| Delrin HP | Excellent | 0.12 | 130 | 90°C / 8h | ★★★★★ | Medical Components | Yes |

Extension

Though Delrin offers excellent moldability, it has practical limits in environments involving long-term exposure to hot water, sealed humidity, or sterilization. To enhance its boundary performance, the industry uses modification blends, stabilizer additives, and protective coatings.With the right formulation and structural design, Delrin’s service life can be significantly extended.

1.Material Blend Optimization: Enhances thermal and water resistance

2.Reinforced Design Structures: Distributes stress from hydrolytic attacks

3.Encapsulation or Coating: Prevents direct vapor exposure

4.Alternative Evaluation: PBT or PA66 may offer better hydrolysis durability

Conclusion

Delrin provides strong mechanical strength and processability, but its hydrolysis limits are jointly influenced by temperature, humidity, and molding practices. Exceeding critical conditions leads to rapid property decline and failure. Designers should assess the operating environment early and apply modification strategies to enhance reliability and longevity.Hydrolysis limits are not barriers—but starting points for smarter design.

For expert assistance in implementing Delrin for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-29-2025