Introduction

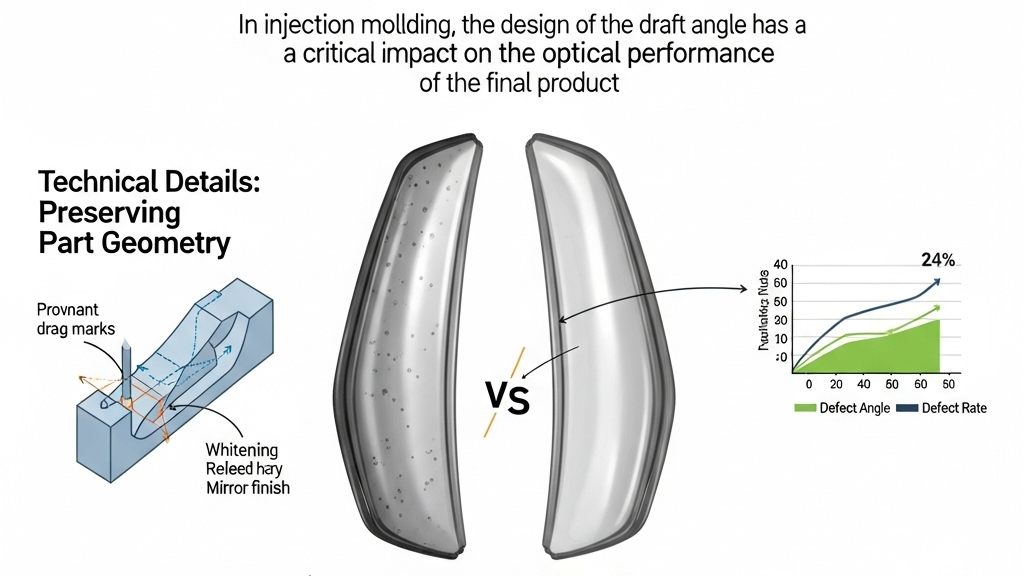

In injection molding, the design of the draft angle has a critical impact on the optical performance of the final product. Insufficient draft can lead to drag marks, whitening, or even impair the mirror finish, which affects both aesthetics and optical functionality. Even minor draft deviations can cause significant problems in high-transparency or mirror-grade parts.

In today’s optical-grade molding, engineers aim to optimize draft design while preserving part geometry, ensuring smooth ejection and surface clarity. Such optimizations are not merely structural—they directly influence product quality and commercial value.

How Does Draft Angle Affect Optical Appearance?

Insufficient draft angle can cause surface defects and frictional marks during ejection, significantly reducing clarity and mirror effects in transparent parts. A well-designed draft enhances mold release and preserves surface integrity.

- Precision Optics Guide: Poor draft causes inconsistent light refraction.

- Clear Part Molding Tips: At least 1° draft helps reduce ejection resistance.

- Surface Integrity: Smooth finish depends on adequate draft relief.

- Temperature Control: Paired with draft, heat control supports defect-free release.

A proper draft angle is the key technical detail to ensure optical performance

Why Do Smaller Draft Angles Cause Surface Defects?

Small draft angles make molds more prone to creating drag marks or micro-cracks, especially on surfaces requiring gloss, reflectivity, or light-guiding properties. Such defects not only affect appearance but also alter light behavior.

- Mold Surface Polishing Standards: Small drafts increase surface damage risks.

- Mirror Part Molding Tactics: Minimum 2° draft helps protect optical surfaces.

- Process Compatibility: High temperature + low draft often causes whitening.

- Tool Steel Considerations: Small drafts demand higher surface precision.

Too small of a draft is a primary risk for damaging optical surfaces

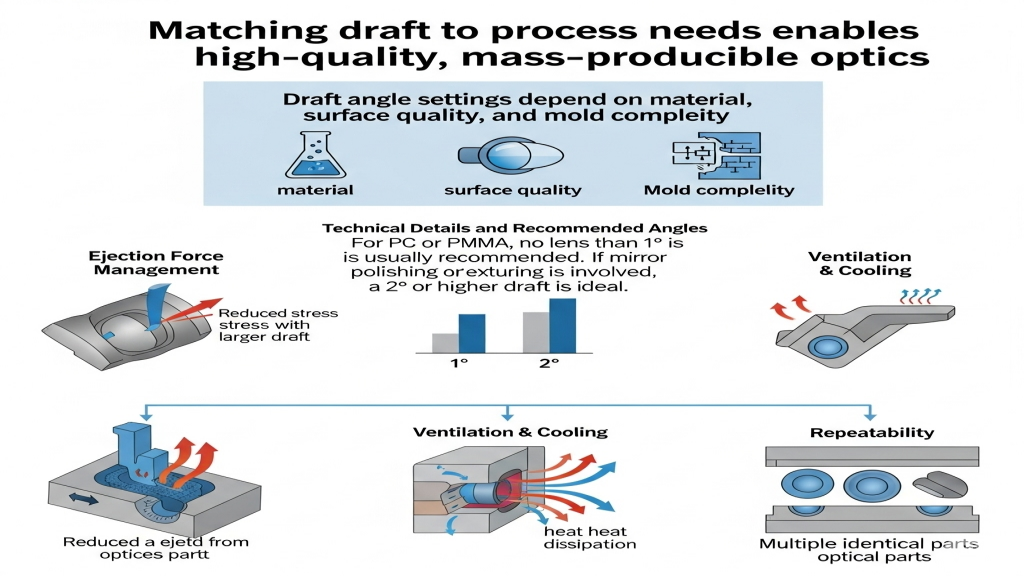

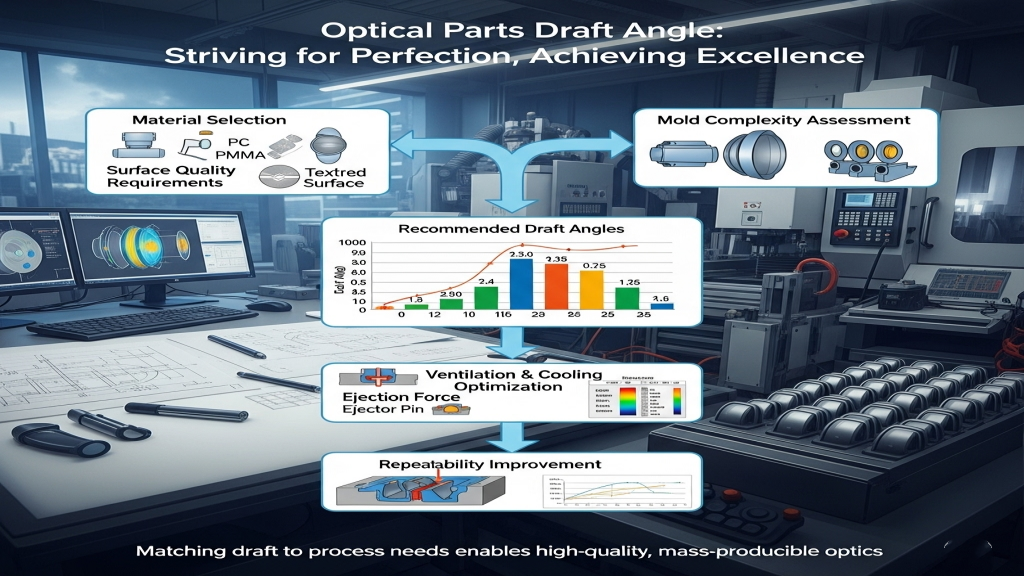

What’s the Best Way to Set Draft Angles for Optical Parts?

Draft angle settings depend on material, surface quality, and mold complexity. For PC or PMMA, a draft of no less than 1° is usually recommended. If mirror polishing or surface texturing is involved, a 2° or higher draft is ideal.

- Recommended Draft Angles: Materials differ in draft needs.

- Ejection Force Management: More draft helps reduce localized stress.

- Ventilation & Cooling: Proper angles aid gas evacuation and thermal flow.

- Repeatability: Larger drafts improve production consistency.

Matching draft to process needs enables high-quality, mass-producible optics

Draft Angle vs. Surface Requirements

|

Surface Type |

Recommended Draft |

Mirror Finish |

Suggested Material |

Scratch Risk |

Cost Impact |

Polishing Needs |

Rating |

| Clear Smooth | ≥2° | Yes | PC/PMMA | Low | Medium | High | ★★★★☆ |

| Matte/Frosted | ≥1° | No | ABS/PC | Medium | Low | Medium | ★★★☆☆ |

| Textured | ≥0.5° | No | PP/ABS | High | Low | Low | ★★☆☆☆ |

| Light Guides | ≥3° | Yes | PMMA | Low | High | Very High | ★★★★★ |

Extended Discussion

In multi-cavity molds or auto-ejector systems, draft design impacts not only visual quality but also tool life and cycle time. Some manufacturers use simulation software to predict light paths based on draft changes and enhance accuracy in the design stage.

1.Draft Simulation: Common in early-stage optical mold validation.

2.Surface Matching Optimization: Directly links draft to product positioning.

3.Custom Draft Solutions: We offer tailored mold design based on optical use cases.

4.Mechanical Enhancements: Optimized drafts support smooth ejection and part stability.

Conclusion

Draft angle is not just a geometric detail—it’s a foundational parameter that determines success in optical injection molding. With precise drafting and surface synergy, transparency, optical performance, and mass-production stability can be achieved. Proper draft is the hidden driver behind high-end optical part success.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-01-2025