Introduction

Mold temperature plays a decisive role in ABS injection molding, as it not only affects the product’s appearance but also influences production efficiency. Proper mold temperature control can significantly improve surface quality and dimensional stability. For precision parts, even small fluctuations may determine the rejection rate.

At different stages of production, mold temperature adjustment helps manufacturers achieve lower defect rates and higher efficiency. The more stable the mold temperature, the more consistent the finished products. For companies, mastering mold temperature control is a key factor in gaining competitiveness.

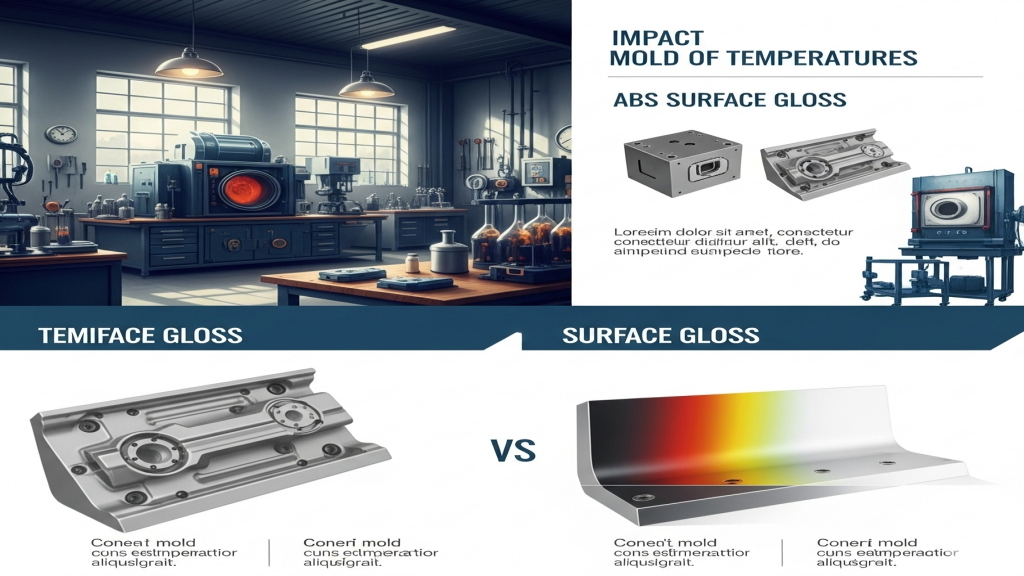

How does mold temperature affect ABS surface gloss?

The mold temperature directly impacts the smoothness and texture of ABS surfaces. Low mold temperature often causes rough surfaces, while excessively high temperature may create stress concentration. By controlling mold temperature, manufacturers can balance gloss and mechanical performance to meet diverse application needs.

- High mold temperature benefits: Enhances gloss and transparency of ABS surfaces.

- Low mold temperature molding: May cause foggy surfaces or weld lines.

- Balanced mold temperature: Provides both aesthetics and strength, ideal for premium products.

- Temperature control technology: Intelligent mold temperature machines ensure consistent results.

Adjusting mold temperature defines the surface quality of ABS products.

What is the role of mold temperature in ABS dimensional stability?

Mold temperature greatly influences ABS shrinkage and dimensional accuracy. At low mold temperature, parts are prone to warpage and uneven shrinkage. With proper mold temperature management, stable dimensions are achievable, minimizing costly rework.

- Mold temperature vs shrinkage: Stable mold temperature reduces dimensional errors.

- Low mold temperature impact: Leads to deformation and internal stress.

- High mold temperature balance: Improves dimensional accuracy for larger parts.

- Smart monitoring: Real-time control increases production yield.

Stable mold temperature is the guarantee of ABS dimensional precision.

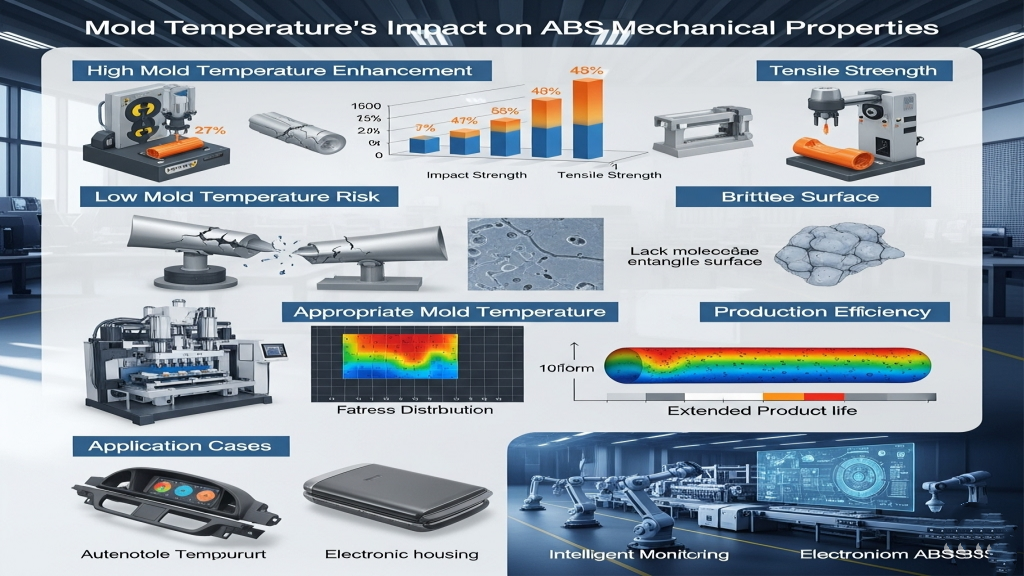

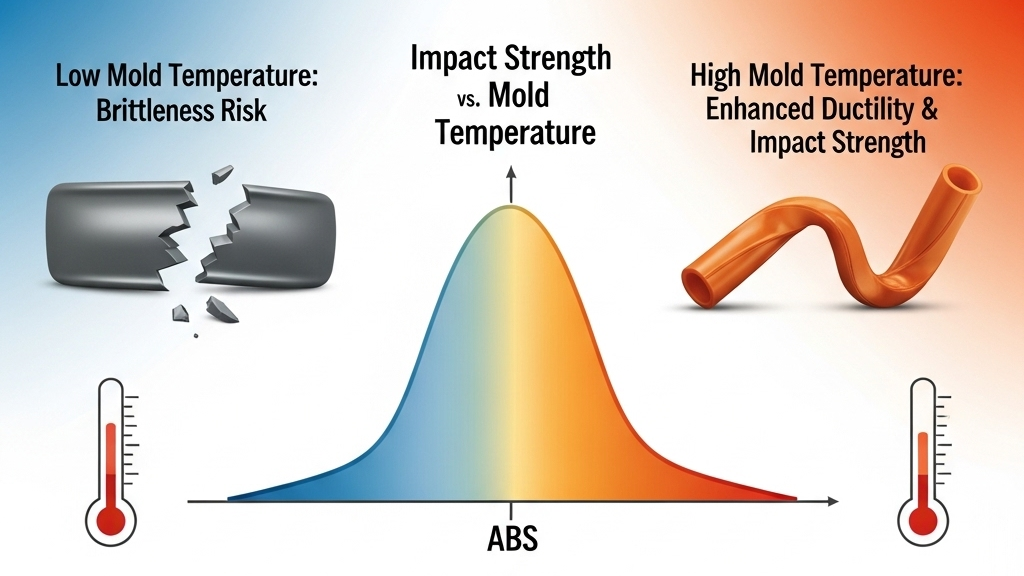

How does mold temperature influence ABS mechanical performance?

Mold temperature is closely tied to ABS toughness and strength. At higher mold temperatures, ABS molecular chains flow more fully, bonding more tightly and improving impact resistance. Conversely, too low mold temperature results in brittleness and crack risk.

- High mold temperature reinforcement: Boosts impact strength and ductility.

- Low mold temperature risk: Leads to brittleness and stress concentration.

- Mold temperature & fatigue: Proper control extends product lifespan.

- Production efficiency effect: Stable mold temperature ensures batch consistency.

Mold temperature regulation greatly enhances ABS mechanical performance.

Mold Temperature Influence Comparison for ABS

|

Mold Temp Level |

Surface Gloss |

Dimensional Stability |

Mechanical Strength |

Production Efficiency |

| Low Temp | Rough finish | Deformation-prone | High brittleness | Faster cycle |

| Medium Temp | Moderate gloss | Stable performance | Balanced strength | Balanced output |

| High Temp | Best gloss | High precision | Toughness improved | Slower cycle |

| Smart Control | Adjustable | High consistency | Reliable strength | Optimized efficiency |

Expansion

In industrial practice, mold temperature management has become the core strategy to enhance ABS product performance. With intelligent mold temperature control systems, manufacturers can improve production stability and customer satisfaction. Mold temperature not only affects product quality but also determines production efficiency and energy consumption.

1.Quality enhancement: Stable temperature reduces defect rates.

2.Energy optimization: Smart mold temperature units reduce power use.

3.Production upgrade: Mold temperature control supports mass production.

4.Market competitiveness: Better quality builds stronger customer trust.

Conclusion

The impact of mold temperature on ABS products extends beyond surface appearance, shaping their structure and application performance. Through scientific mold temperature control, companies can achieve optimized surface quality, dimensional accuracy, and mechanical strength. In the future, intelligent mold temperature regulation will drive industry upgrades, bringing higher efficiency and stronger competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-19-2025