Introduction

Grinding interrupted surfaces is a highly challenging task, commonly seen in gears, slots, and keyways. These patterns create interrupted contact, leading to force fluctuations, chatter, and burns during grinding. Mastering key control techniques is essential to solving this problem.

For CNC machining businesses, failure to address interrupted grinding issues in time may result in high scrap rates and equipment damage. A systematic approach—spanning process setup to equipment configuration—is required. System thinking is the key to achieving high yield.

Why does interrupted grinding easily cause chatter?

During grinding of interrupted surfaces, intermittent contact between abrasive and workpiece triggers periodic shock. This unstable cutting force often results in machine vibration.

- Insufficient dynamic stiffness: Machine structure lacks stability.

- Improper tool selection: Grinding wheel structure doesn’t suit interrupted impact.

- Wrong grinding parameters: Mismatch in feed and speed settings.

- No real-time feedback: Absence of vibration monitoring systems.

Interrupted grinding impact must be controlled through rigidity and parameter synergy.

How does hardness variation amplify grinding risks?

Hardness inconsistency leads to uneven stress distribution, especially at boundaries of interrupted structures. This increases uneven wear, burns, and risk of microcracks.

- Unstable microstructure: Caused by heat treatment or casting.

- Residual stress not released: Inadequate pre-processing.

- Localized hard spots: Imbalance in wheel load.

- Unoptimized CNC path: Poor entry angle control.

To address material differences, precise pre-treatment and path design are essential.

Can poor fixture design affect grinding stability on interrupted surfaces?

Interrupted surfaces often involve irregular geometry. Improper clamping leads to vibration. Clamping instability amplifies initial grinding shocks.

- Too few contact points: Parts shift under force.

- Mismatch of fixture type: Doesn’t suit workpiece shape.

- Lack of vibration damping: No damping measures on fixture.

- Low automation accuracy: Repeatability issues in clamping.

Fixtures are not just holders—they’re the first defense against vibration.

Comparison of 4 Common Failure Modes in Interrupted Grinding

|

Failure Mode |

Cause |

Affected Area |

Reversible |

Detection |

Solution |

Impact on Equipment |

| Burn | Instant Overheat | Surface Layer | No | Color/Microscopy | Lower feed + coolant | High |

| Chatter Marks | Repetitive Impact | Full Surface | No | Visual/Profile Meter | Rigidity + damping | Medium |

| Microcracks | Stress Accumulation | Edges | No | Ultrasonic | Gradient hardening | High |

| Grit Breakout | Process mismatch | Contact Points | Yes | Sound change | Wheel dressing change | Medium |

Expansion

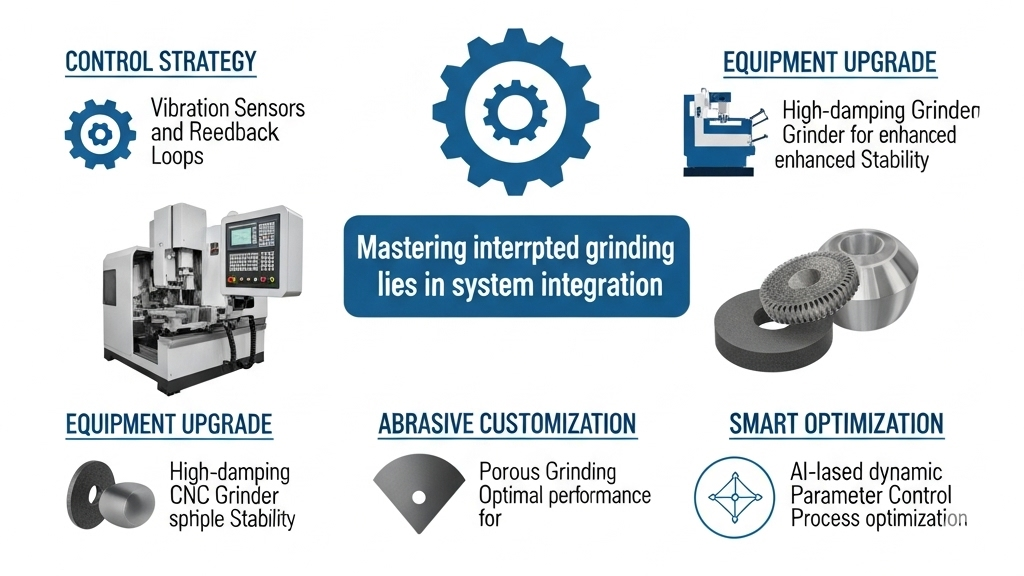

Interrupted grinding challenges not only apply to small-batch operations but also scale into high-volume CNC automation. Mastering interrupted grinding lies in system integration—from process parameters to cooling and software.

1.Control Strategy: Add vibration sensors for feedback.

2.Equipment Upgrade: Choose high-damping CNC grinders.

3.Abrasive Customization: Use porous grinding wheels.

4.Smart Optimization: AI-based dynamic parameter control.

Conclusion

Interrupted surface grinding isn’t an unsolvable riddle—it requires breaking traditional boundaries and optimizing systems in fixture, equipment, material, and process. Only when all components form a closed-loop response can grinding become stable.

Pushing digital manufacturing upgrades is the key to resolving interrupted grinding barriers. Ongoing optimization and interdisciplinary collaboration will be the foundation for winning market trust.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-25-2025