In the field of digital manufacturing, resin 3D printing is favored by designers for its fine details and smooth surfaces. However, the brittleness of printed parts makes prototypes prone to failure during functional testing and assembly impact. The brittleness of resin is quietly slowing down the pace of innovation. To maintain a high iteration speed, companies are seeking alternative processes that balance precision and toughness for more robust product validation.

Modern injection molding technology, supported by modified polymers and optimized mold designs, has made significant progress in impact resistance. More and more brands are shifting from printing to low-volume molding in the prototyping phase to obtain reliable mechanical performance. Injection molding is becoming the critical bridge that fills the brittleness gap from design to production. This trend opens new business opportunities for material providers and molding service vendors.

Is Resin Brittleness Killing Functional Validation?

Engineers often find resin parts cracking during first assembly, forcing them to reduce loading or redesign structures. This extends the development cycle and increases tooling costs. When brittleness leads to functional failure, commercialization is directly delayed. Switching to micro-injection enables usable engineering-grade parts within the same iteration window.

- Polymer Modification: Improved formulas enhance elongation without sacrificing detail.

- Post-Curing: UV and thermal curing enhance toughness without affecting dimensions.

- Trial Injection Molding: Aluminum tooling enables 10× impact strength at 30% of the cost.

- Structure Simulation: FEM predicts stress points and guides design reinforcement.

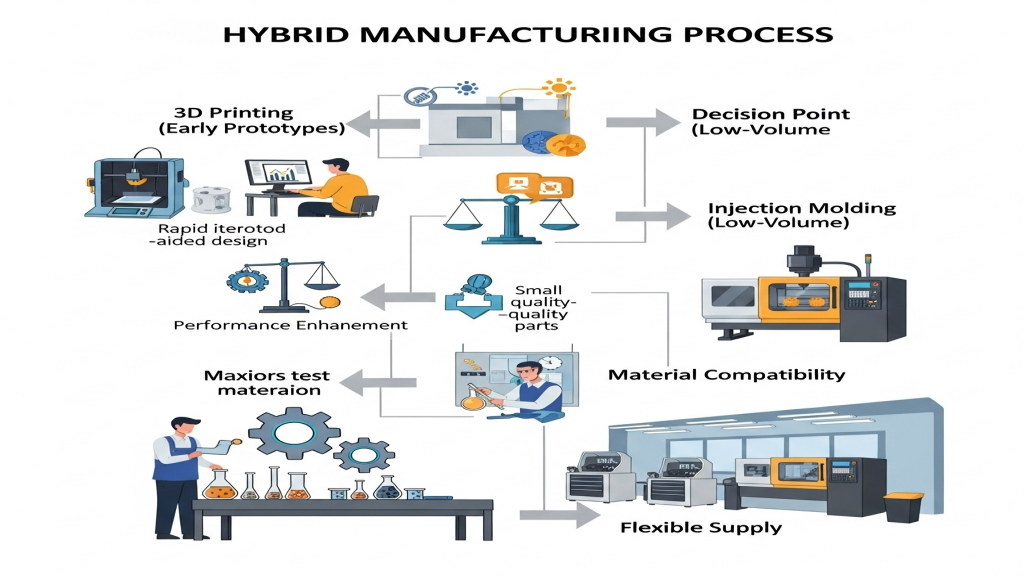

Can Hybrid Processes Balance Cost and Performance?

Adopting 3D printing in early prototypes and switching to molding before launch is a mainstream strategy. This model leverages the rapid iteration advantage of printing and avoids cracking at the final validation stage. The hybrid path helps teams achieve near-production validation within budget. The key is deciding the right transition point and compatible material systems.

- Rapid Validation: Focus on appearance and fit validation to shorten freeze time.

- Cost Relief: Small-batch molding spreads tooling cost and reduces unit cost by 40%.

- Material Compatibility: Using modified PC similar to final mass production avoids redundant testing.

- Flexible Supply: Vendors adapt processing routes to buffer against supply fluctuations.

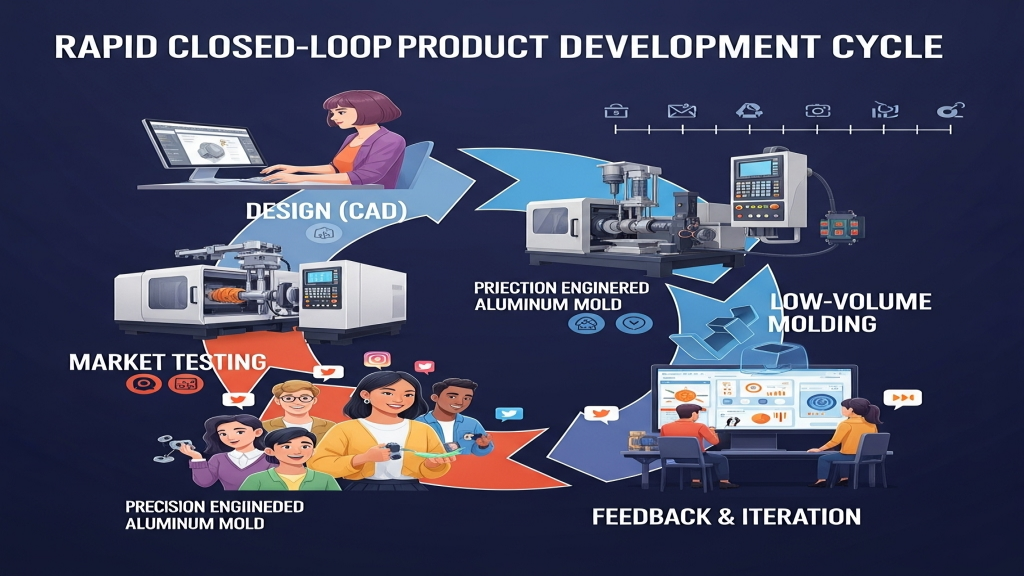

Can Low-Volume Molding Speed Up Launch?

Compared to fragile resin parts, low-volume molded parts can be used directly for market testing. Soft tooling allows thousands of functional parts in two weeks. This “sell while iterating” model is reshaping product launch cycles. It allows enterprises to invest in expensive steel molds only after confirming end-user demand.

- Accelerated Testing: Pre-sales help validate market acceptance and gather feedback.

- Closed-Loop Iteration: Molding feedback integrates into CAD for continuous design updates.

- Capital Optimization: Reduces upfront investment, frees funds for go-to-market.

- Consistent Quality: Tolerances closely match production parts, cutting verification cycles.

Process Comparison Table

|

Index |

Resin Print |

Molding PC |

Molding PA |

Hybrid |

| Impact | Low | High | Medium | Medium |

| Cost/Part | Medium | Low | Low | Medium |

| Cycle | Fast | Medium | Medium | Fast |

| Scale | Limited | High | High | Medium |

Expansion

Advances in material science are expanding product capabilities, but commercial success still relies on scalable manufacturing. As resin printing matures toward micro-feature tuning, injection molding is consolidating its position with proven cost and supply benefits. The real breakthrough comes from integrating both into one workflow. Companies embracing hybrid manufacturing are leading the next wave of hardware innovation.

1.Forming Optimization: Balanced gating minimizes short shots and stress.

2.Supply Integration: Upstream-downstream collaboration shortens delivery time.

3.Quality Digitization: Real-time monitoring drives continuous improvement.

4.Market Pre-positioning: Launch marketing during prototyping to lock in users.

Conclusion

The brittleness of resin printing is not the end, but the start of discovering better paths. Hybrid manufacturing enables a complete loop from design validation to market entry. When the toughness of molding combines with the flexibility of printing, design bottlenecks vanish. Only by mastering every evolution in materials and processes can companies rise above the competition.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-19-2025