Introduction

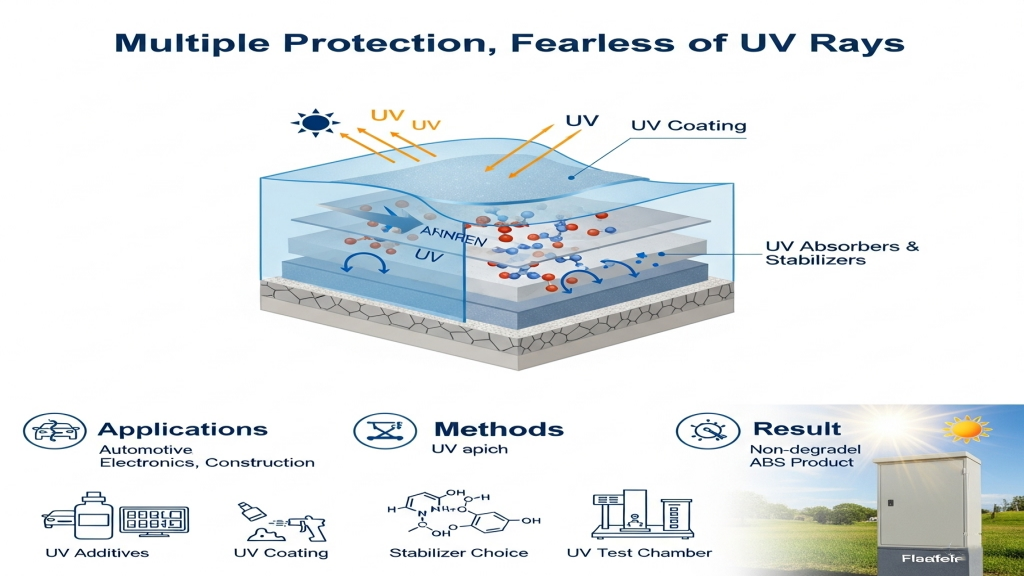

ABS (Acrylonitrile-Butadiene-Styrene copolymer) is widely used in industries such as automotive and electronics, especially for outdoor applications. To extend the lifespan of ABS, UV resistance technology has become a key modification that effectively counters UV degradation, thus prolonging the stability of the product.

By adding UV-resistant additives or surface coatings, the weather resistance and UV protection of ABS are significantly enhanced. The introduction of this technology not only improves product performance but also expands the application range of ABS in high-demand environments.

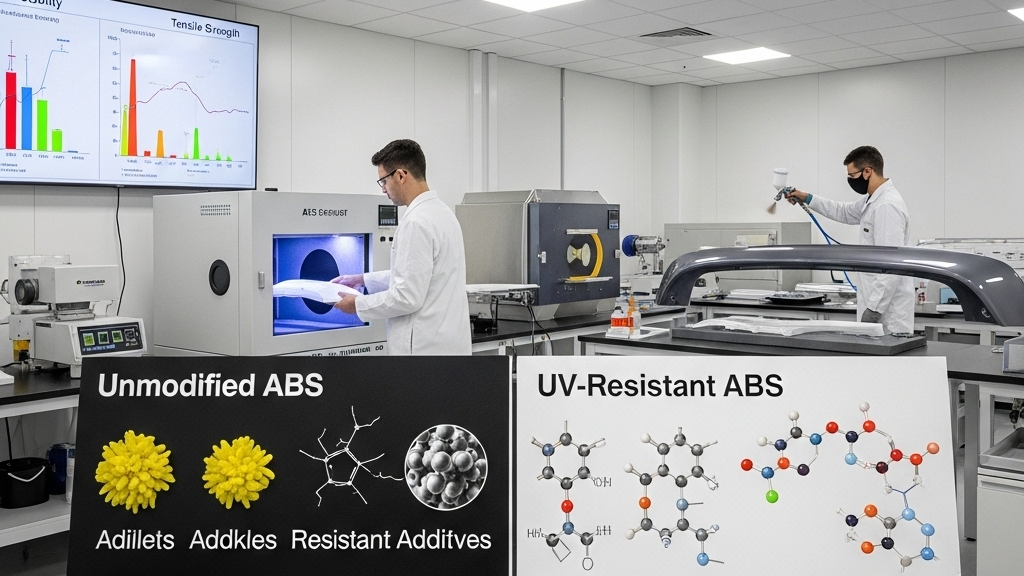

How to Enhance UV Resistance of ABS?

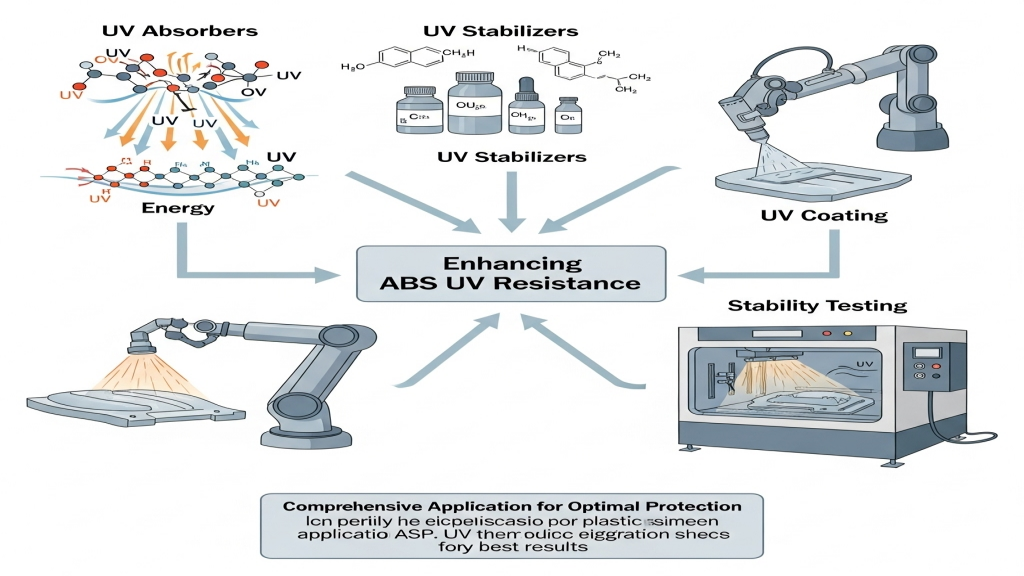

The enhancement of ABS UV resistance is typically achieved through the addition of UV-resistant agents. UV additives absorb UV rays and convert them into heat, reducing UV damage to the material. This method is particularly effective for applications exposed to sunlight for extended periods. When selecting UV-resistant materials, companies often need to consider their long-term weather resistance.

- UV Coating Applications: Coating technology effectively enhances external UV protection.

- Add UV Absorbers: Click to see the role of additives.

- Choose UV Stabilizers: Different UV stabilizers have varying resistance levels.

- UV Stability Testing: Click to view testing methods.

To achieve optimal UV protection, combining multiple technologies is the best choice.

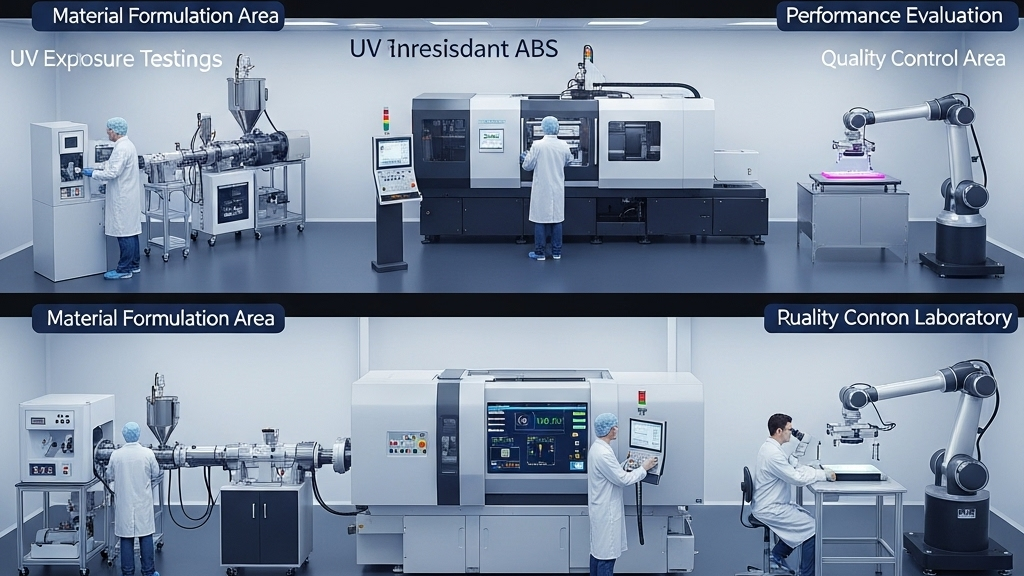

How to Ensure Stable UV Performance in Injection Molded ABS?

The stability of UV resistance in injection-molded ABS requires optimization of formulation and production processes. By adjusting injection molding parameters such as temperature and cooling rates, UV performance can be improved while maintaining physical properties. During production, the right amount of UV absorber must be added to achieve this goal. Additionally, UV stability should be tested to meet specific application requirements.

- Optimize Injection Temperature: Proper temperature helps enhance UV resistance.

- Choose Suitable UV Additives: Click to see suitable additives.

- UV Aging Testing: Use UV aging tests to evaluate long-term stability.

- Injection Molding Process Impact: Controlling process parameters is crucial for UV protection.

Details in the injection molding process determine UV resistance, optimizing these processes can effectively extend product lifespan.

How Does ABS UV Performance Vary in Different Environments?

ABS UV resistance performance varies significantly in different environments. High temperatures, humidity, and strong UV rays accelerate material aging, so ABS used in these conditions must pay special attention to UV resistance. For ABS products exposed outdoors for extended periods, using specialized UV stabilizers and protective coatings can effectively reduce the impact of environmental factors on performance.

- Impact of High Temperature: High temperature accelerates UV degradation.

- Impact of Moisture: Click to see the relationship between moisture and UV.

- UV Intensity: Strong UV rays accelerate material aging.

- UV Coating Effectiveness: Coatings effectively extend material lifespan.

Understanding environmental impacts and taking targeted measures helps improve ABS UV resistance in harsh conditions.

Table Title

|

Environmental Factors |

High Temperature |

Strong UV |

High Humidity |

UV Coating Effect |

| ABS Performance Changes | Accelerates aging | Accelerates degradation | Speeds up degradation | Extends lifespan |

| Impact Level | High | High | Medium | High |

| Recommended Solutions | Use UV-resistant additives | Add UV absorbers | Enhance coating protection | Use efficient UV stabilizers |

How to Choose the Right UV Resistant ABS

The key to choosing the right UV-resistant ABS material lies in considering both performance and cost based on actual needs. By carefully selecting UV grades and additives, companies can maximize their product’s market competitiveness. Balancing performance and cost is crucial for different applications.

1.Choose Suitable UV Stabilizers: The type of UV stabilizer directly affects performance.

2.Consider Environmental Factors: Different environments require varying UV resistance levels.

3.Optimize Material Formulation: Enhance overall material performance by optimizing formulation.

4.Cost vs. Performance Balance: Ensure economic benefit and market demand are met.

Conclusion

Improving ABS material’s UV resistance is critical, and adding the right UV stabilizers along with optimizing injection molding processes can significantly extend material lifespan. Companies should choose the most suitable UV solution based on actual usage environment and cost considerations, ensuring product reliability in outdoor environments.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-21-2025