Lightweight ABS is driving a new wave of innovation in the injection molding industry, offering excellent processability and weight reduction. It significantly lowers manufacturing costs while maintaining structural integrity and reliability.In practical applications, lightweight ABS has become the preferred material in consumer electronics and automotive components.

By improving molding processes and material selection, companies can easily respond to the dual demands of cost reduction and performance improvement. Its flexibility in customized solutions enables it to adapt to various industrial needs.

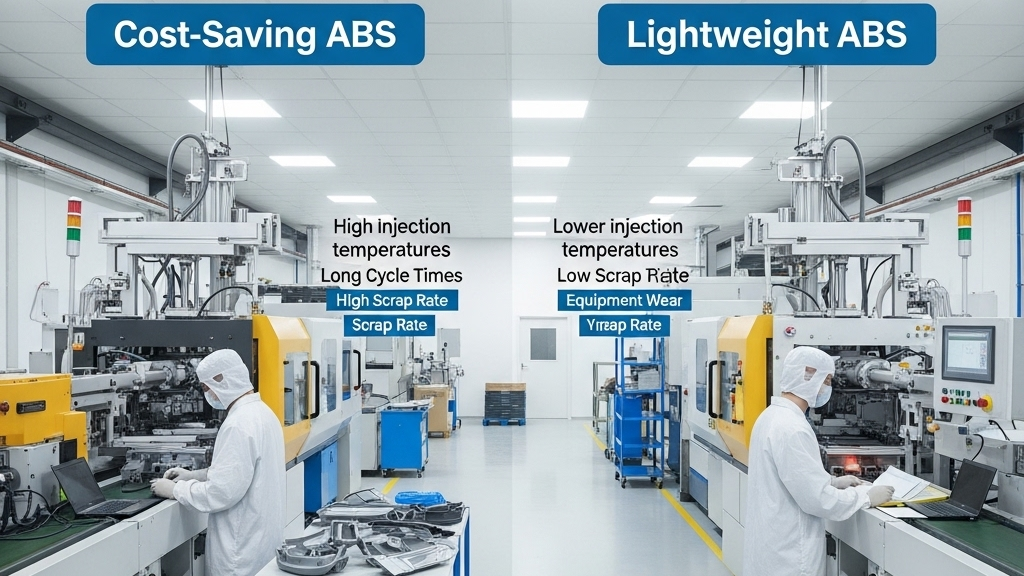

How Does Lightweight ABS Reduce Overall Manufacturing Costs?

Lightweight ABS offers high molding efficiency, reducing cycle time and raw material usage. Its thermal stability helps minimize scrap rates and energy consumption. These advantages make it a standout performer in cost control.

- Reduced Material Consumption: Lower density means less material per part.

- Energy Efficiency: Lower processing temperatures save electricity.

- Less Equipment Wear: Excellent flow properties reduce machine abrasion.

- High Batch Consistency: Stable performance ensures high yield rates.

How Does It Balance Performance and Lightweighting?

Through structural tuning and compound modification, lightweight ABS maintains excellent impact resistance and stiffness, ensuring strength is not sacrificed for weight.This “lightweight advantage” has been validated across multiple industrial products.

- Multi-layer Formulations: Enhances rigidity and impact strength.

- Structural Integrity Preserved: Maintains strength despite weight reduction.

- High Molding Accuracy: Excellent fluidity supports complex parts.

- Thermal Stability: Suitable for diverse environmental conditions.

How Does Lightweight ABS Add Value Across Applications?

In automotive interiors, smart appliances, and 3C housings, lightweight ABS continues to gain ground due to its balanced properties and processability.Its cross-sector adaptability makes it a strategic choice for future-ready manufacturing.

- Multi-industry Compatibility: Widely applicable from automotive to electronics.

- Excellent Surface Finish: Ideal for electroplating, printing, or coating.

- UV and Weather Resistance: Suitable for outdoor or demanding environments.

- Environmentally Friendly: Recyclable and aligned with sustainable production.

Performance & Cost Comparison Table

|

Property |

Lightweight ABS |

Regular ABS |

PP Material |

PC (Polycarbonate) |

| Density (g/cm³) | 1.03 | 1.06 | 0.90 | 1.20 |

| Impact Strength | Excellent | Good | Moderate | Excellent |

| Molding Cycle | Short | Medium | Short | Long |

| Energy Consumption | Low | Medium | Low | High |

| Surface Finish | Excellent | Excellent | Average | Good |

| Cost Control | Strong | Medium | Strong | Weak |

| Eco-Friendliness | Good | Average | Good | Average |

| Application Scope | Broad | Broad | Partial | Specific |

How Does Lightweight ABS Drive Next-Gen Injection Molding?

Lightweight ABS is redefining the material foundation of the injection molding industry with its versatility and cost-effectiveness. It lowers production barriers while unlocking new possibilities for product innovation. From cost management to structural creativity, it provides a renewed material strategy for manufacturers.

1.Supports Lightweight Design: Ideal for modern products that demand less weight.

2.Enables Structural Innovation: Suitable for intricate mold structures.

3.Promotes Green Manufacturing: Adds value through lower emissions and recyclability.

4.Expands Use Cases: Penetrates medical, electronics, and more industries.

Conclusion

Lightweight ABS injection technology optimizes manufacturing costs while ensuring reliable product performance. Its adaptability across different use cases gives companies a distinct competitive edge.Looking ahead, lightweight ABS is poised to become a strategic material across broader industrial sectors.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-06-2025