Introduction

In modern injection molding, achieving ultra-high elasticity relies on the seamless integration of material selection and precise process control. The arrangement and compatibility of polymer chains determine the product’s extensibility and rebound performance. Through optimized composite formulations and flexible additives, molded parts can retain shape memory while withstanding repeated mechanical stress.

Meanwhile, advancements in mold temperature and flow control have enabled greater precision when molding flexible materials. This precision ensures product consistency and durability, offering customers superior customized solutions. As a result, ultra-elastic injection-molded parts are becoming the preferred choice in automotive, consumer electronics, and sports equipment industries.

How Can Material Formulation Achieve Ultra-High Elasticity?

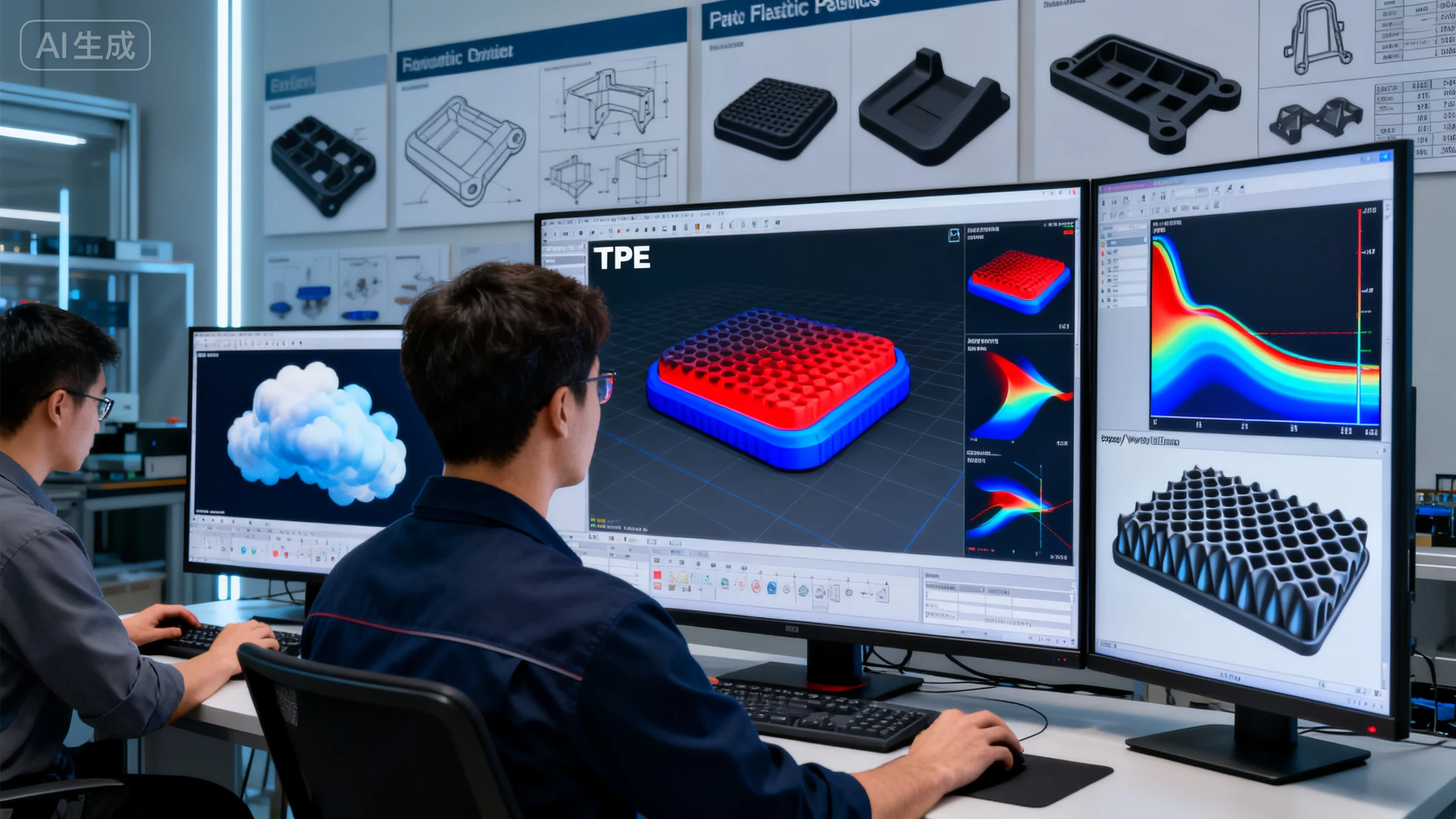

Material formulation is the core factor influencing elasticity performance. Selecting materials such as TPE, TPU, or modified silicone with high elongation at break is fundamental. These materials retain molecular chain flexibility during molding, while plasticizers and compatibilizers enhance overall softness and fatigue resistance.

- TPE Modification Technology: Enhances tensile and compression recovery through molecular design.

- TPU Compound Systems: Improves low-temperature elasticity and abrasion resistance.

- Softening Additives: Enhances touch comfort and shape recovery.

- Surface Energy Regulation: Controls molecular activity at bonding interfaces.

Ultra-high elasticity begins with scientific control of molecular structure.

How Do Processing Parameters Affect Elastic Performance?

Processing temperature, injection speed, and holding pressure have a direct impact on elasticity. Excessive melt temperature or high shear rate can break molecular chains and reduce rebound properties. Proper cooling time and temperature uniformity promote chain relaxation and improve flexibility.

- Temperature Window Control: Prevents material degradation through precise heat management.

- Holding Pressure Optimization: Minimizes residual stress and improves stability.

- Flow Balance Design: Reduces hard zones caused by molecular orientation.

- Mold Cooling System Adjustment: Regulates crystallization speed and stress release.

A well-defined processing window is key to maintaining elasticity.

How Can Structural Design Support High Elasticity in Injection Molding?

Optimizing geometry during the design phase has a significant effect on elasticity. Wall thickness, fillet transitions, and rib layouts determine stress distribution and deformation absorption. Proper design enhances comfort while minimizing risk of fracture or permanent deformation under strain.

- Stress Distribution Design: Prevents concentration at sharp corners.

- Simulation Analysis Tools: Predicts elastic deformation zones in advance.

- Balanced Thickness Ratios: Ensures even flow and deformation uniformity.

- Rebound Structure Design: Provides additional shape memory capacity.

Structural optimization bridges elasticity and long-term durability.

Comparison Table of High-Elastic Materials

|

Material Type |

Elongation (%) |

Rebound (%) |

Fatigue Resistance |

Cost Level |

| TPE | 400-600 | 80 | High | Medium |

| TPU | 500-700 | 90 | Very High | High |

| Silicone | 600-800 | 85 | Extremely High | Higher |

| SBS Modified | 300-500 | 75 | Moderate | Low |

Interested in finding the best material for your product design? contact us for customized formulation advice.

Expansion

High-elastic molding technology is redefining the limits of traditional rubber, becoming a key approach for lightweight structural design. Through intelligent mold temperature systems and dynamic pressure feedback, high-elastic materials can be molded with extreme accuracy. Moreover, recyclable elastomer solutions now enable manufacturers to balance high performance with sustainability.

1.Multi-component Overmolding: Integrates soft-hard structures seamlessly.

2.Microcellular Injection Process: Reduces part weight while maintaining elasticity.

3.Bionic Texture Design: Enhances grip and tactile experience.

4.Customized Mold Development: Adapts flow patterns to various elastic materials.

Conclusion

Achieving ultra-high elasticity in injection-molded parts is not the result of a single parameter but the synergy of material science, processing, and design. Only by combining molecular flexibility with precise process control can we realize a true “elastic revolution.” This not only improves user experience but also strengthens a company’s competitive edge. Continuous innovation and expertise remain the driving forces behind delivering value to customers.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-15-2025