Conductive plastic masterbatches fundamentally alter the charge transfer path by dispersing carbon-based or metallic fillers uniformly in the polymer matrix. These materials allow housings, fixtures, and structural parts to achieve both mechanical strength and electrical properties in one injection molding process. This innovation significantly reduces the cost of metal replacement and secondary coating, benefiting the entire supply chain.

With the rise of 5G devices, energy storage modules, and smart factories, long-term ESD protection and signal shielding have become baseline requirements for product reliability. Conductive masterbatches, combined with precise process control, can maintain stable surface resistance from -40 °C to 120 °C, preventing system failure due to electrostatic discharge. As a result, companies can offer longer warranties and faster time-to-market, gaining a competitive edge in both additive manufacturing and injection molding sectors.

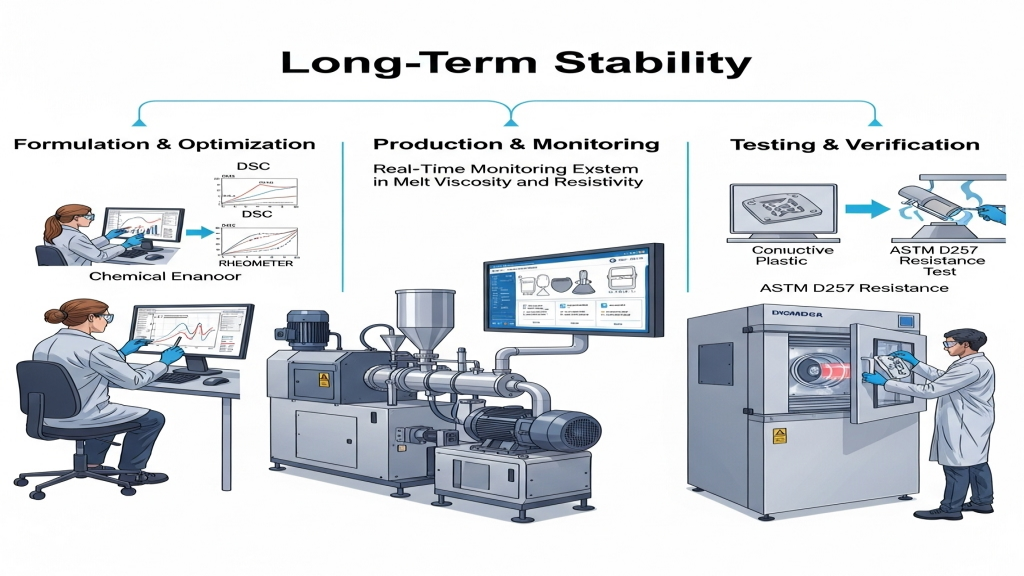

How Can Conductive Pathways Remain Stable Over Time in Injection Molding?

Under high shear, carbon nanotubes and polymer chains form a continuous conductive network that provides predictable volume resistivity. Dispersants and lubricants in the masterbatch prevent filler agglomeration, ensuring a balance between melt viscosity and cavity filling. A well-connected network means molded parts can retain 10⁴ Ω surface resistance after aging, with no need for additional coating or baking.

- Balanced Formulation: Optimize filler content and shear sensitivity to reduce injection pressure.

- Uniform Compounding: High-torque twin-screw extruders ensure nanoscale dispersion and network integrity.

- Testing & Verification: ASTM D257 periodic testing validates long-term conductivity.

- Smart Monitoring: Online viscosity-resistance feedback improves consistency.

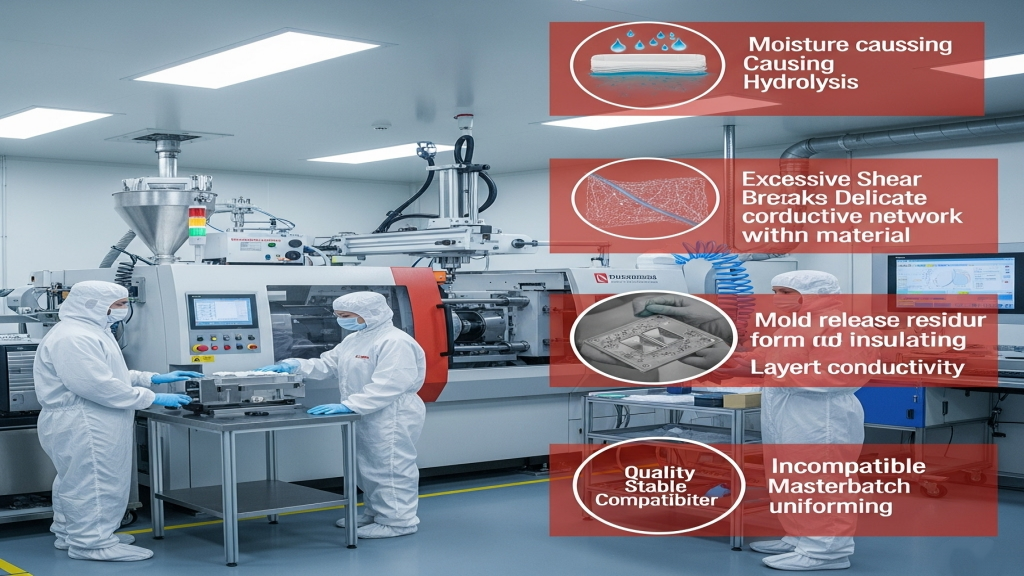

What Factors During Production Could Degrade Conductivity?

Moisture, re-heating, and excessive shear can damage the conductive network, resulting in high surface resistance. Excess mold release residue may form insulating films at the interface, blocking charge flow. Maintaining low moisture content and stable processing temperatures is key to preserving conductivity.

- Drying Process: Low dew-point drying prevents hydrolysis and voids.

- Molding Temperature Control: Stable mold temperature reduces thermal degradation.

- Mold Cleaning: Regular cleaning prevents accumulation of insulating deposits.

- Color Masterbatch Compatibility: Use same-base carriers to avoid network dilution.

How Is Long-Term Durability of Conductive Parts Verified?

Lab aging tests including humidity, salt spray, and cyclic loading assess the integrity of the conductive network. Parts are considered “permanently conductive” if surface resistance changes ≤1 log step after 500 h salt spray exposure. Data from accelerated aging enables faster product certification and market readiness.

- Accelerated Aging: Thermal-humidity-UV cycles quickly screen materials.

- Mechanical Fatigue: Evaluate breakage threshold of the conductive network under cyclic stress.

- Resistance Monitoring: Track resistance curve over time in real-time.

- Failure Analysis: SEM imaging identifies filler separation or broken network points.

Conductive Masterbatch Performance Matrix

|

Property |

Carbon Black |

Graphite |

CNT |

Metal Fiber |

| Surface Resistivity (Ω) | 10⁴ | 10⁴ | 10³ | 10² |

| Processing Flow | Good | Moderate | Good | Medium |

| Cost Index | ★★ | ★★★ | ★★★★ | ★★ |

| Shielding Efficiency (dB) | 20 | 25 | 35 | 45 |

Expansion

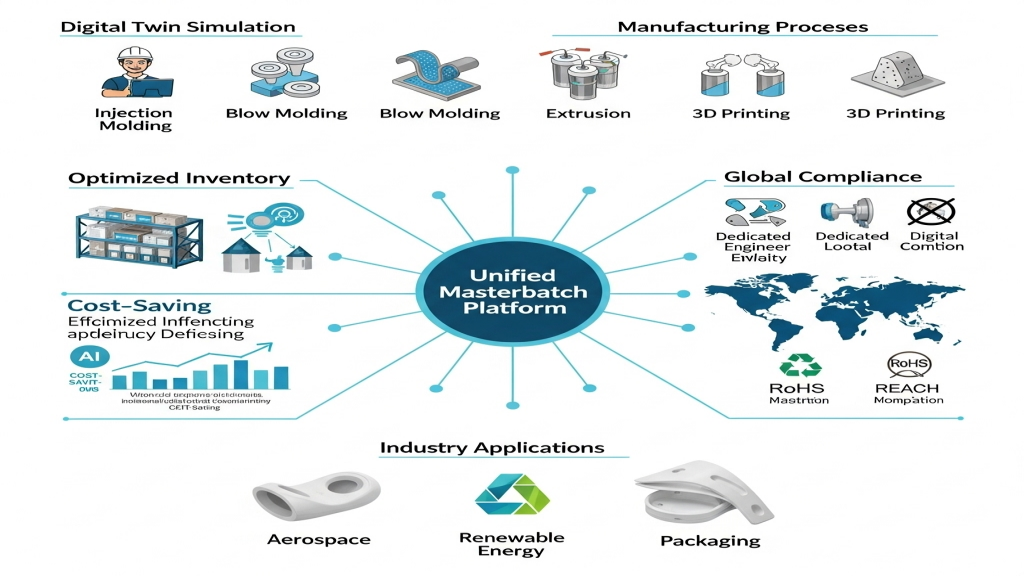

Conductive plastic masterbatches are suitable not only for injection molding but also for blow molding, extrusion, and 3D printing, extending their application to packaging, aerospace, and renewable energy. Companies can leverage a unified masterbatch platform across multiple processes to minimize inventory and improve purchasing leverage. Through digital twin simulation, designers can predict resistivity and flow behavior during the early stages, accelerating time-to-market.

1.Cross-Process Compatibility: One formulation covers injection and extrusion.

2.Inventory Optimization: Platform materials reduce warehouse cost.

3.Digital Simulation: CAE tools predict conductive network behavior.

4.Global Compliance: Meets RoHS and REACH regulations.

Conclusion

Conductive plastic masterbatches provide injection molded parts with permanent electrical performance, enabling single-shot molding to meet both ESD and shielding standards. Thanks to stable conductivity and broad processing compatibility, they are ideal replacements for metals and coatings. Through precise formulation, process control, and accelerated aging validation, manufacturers can confidently promise extended warranties. As a result, conductive masterbatches are driving value-added upgrades and sustainable innovation in the injection molding industry.

For expert assistance in implementing conductive masterbatch solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-20-2025