In high-precision injection molding, the alignment between mold and inserts determines the final product’s appearance and dimensional accuracy. Precise fitting not only improves yield rate but also significantly shortens mold trials and development time.

With digital engineering and real-time inspection, companies can achieve a seamless design-to-production verification cycle. Data-driven workflows make business decisions more compelling.

How to Improve Insert Positioning Accuracy?

High precision relies on robust datum design, rigid fixtures, and closed-loop tolerance control. A unified coordinate system helps eliminate cumulative deviation.

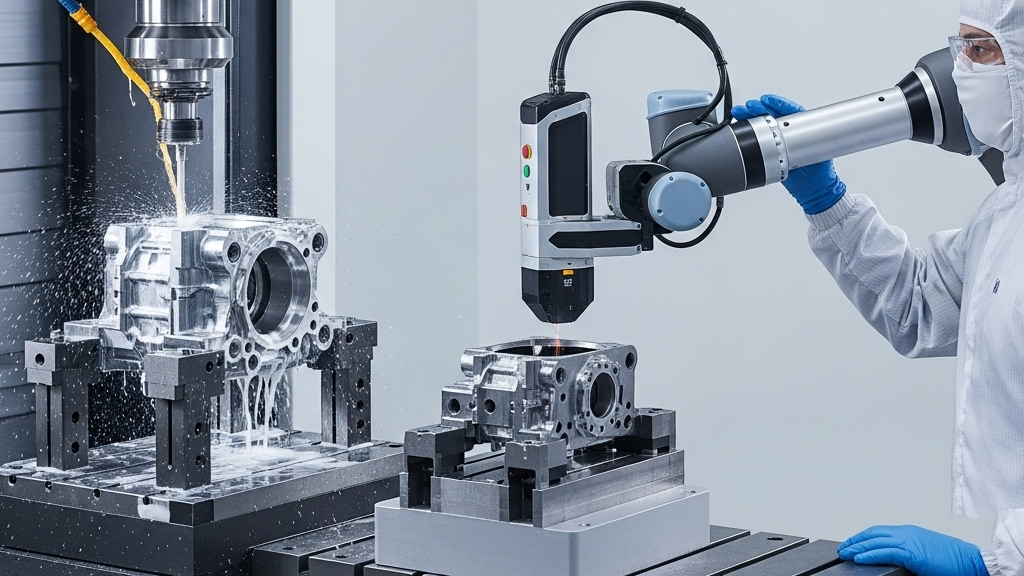

- High-Precision CNC: Micron-level cutting ensures dimensional accuracy

- Laser Metrology: Non-contact scans instantly spot misalignment

- Data Matching: Synchronized CAD/CAM updates prevent drawing inconsistencies

- Quick Iteration: Plug-in insert design allows for local revisions

How to Ensure Consistent Machining Tolerances?

From blank preparation to precision grinding, every step requires standardized tool wear control and thermal compensation. Constant-temperature environments reduce thermal expansion error.

- PVD Tools: Wear-resistant coating maintains cutting stability

- Thermal Fixtures: Temperature-controlled base avoids drift

- Smart Processes: SPC monitoring triggers automatic alarms

- Precision Grinding: Final surface roughness ≤ Ra0.2 µm

How to Maintain Fit Accuracy During Mass Production?

In mass production, repeatability and maintenance become more critical than individual part accuracy. Real-time monitoring detects potential deviations before batch scrap.

- MES Monitoring: Immediate stop upon deviation detection

- Spot QA: Robotic sampling every hour

- Wear Alert: Clamping torque trends detect mold base shift

- Fast Mold Change: Modular interfaces minimize downtime

Fit Solution Comparison Table

|

Method |

Accuracy (μm) |

Cost |

Adjustment Difficulty |

Suitable for Mass Production |

| Standard Process | ±25 | ★ | Low | Medium |

| CNC Grinding | ±10 | ★★ | Medium | High |

| Laser Hybrid | ±5 | ★★★ | High | High |

| Onsite Polishing | ±15 | ★ | Medium-Low | Medium |

Expansion

Precision fitting impacts more than a single project—it affects brand image and bargaining power in high-end markets. The industry is moving toward digital twins and predictive maintenance. Companies with early deployment will secure the profit advantage.

1.Tailored Training: Equip teams with micron-level machining skills

2.Digital Twin: Simulate wear and forecast output in real-time

3.Supply Chain Sync: Shared components reduce procurement time

4.Green Manufacturing: Precision reduces material waste and rework

Conclusion

Precise mold-insert fitting is the cornerstone of high yield and low cost. With proactive design, closed-loop feedback, and intelligent monitoring, companies can maintain leadership. Treating precision as a business strategy, not just technical detail, builds customer trust. Future-ready technologies like digital twins and auto-compensation will strengthen this edge.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-16-2025