Introduction

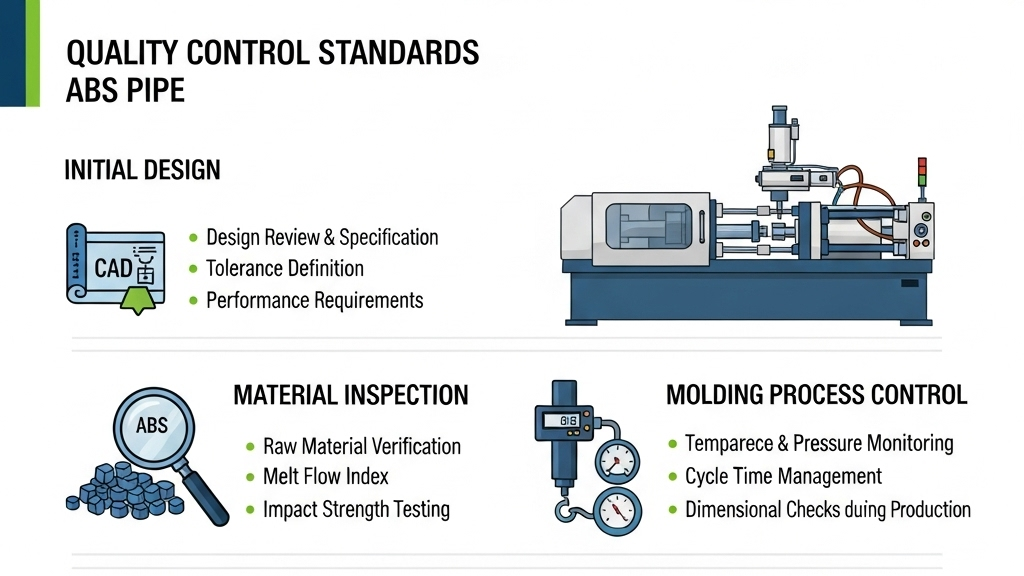

In the plastic injection molding industry, defining quality control standards for ABS pipe fittings is crucial. Whether in the initial design or during the production phase, clear quality control standards ensure the stability and reliability of the product. Setting a strict set of quality control standards not only improves product quality but also reduces issues during production. For customers, products that meet these high standards will be more competitive in the market.

How to Determine the Basic Quality Requirements for ABS Pipe Fittings?

When defining quality control standards for ABS pipe fittings, the first priority is to clarify the basic quality requirements. These standards will cover aspects such as material selection, injection molding processes, dimensional tolerances, and more. Clarifying these basic requirements is essential to ensure the stability of pipe fitting quality.

- Material Selection: Choosing the appropriate ABS resin is key to ensuring the strength and durability of the pipe fittings.

- Injection Molding Process Optimization: By fine-tuning the injection molding process, each pipe fitting can be ensured to meet the standards.

- Dimensional Control: Accurate dimensional tolerances are critical for ensuring the fitting’s precision.

- Surface Quality: Strict surface checks ensure the pipe fittings are defect-free and scratch-free.

Controlling every aspect from material selection to final product ensures overall quality stability.

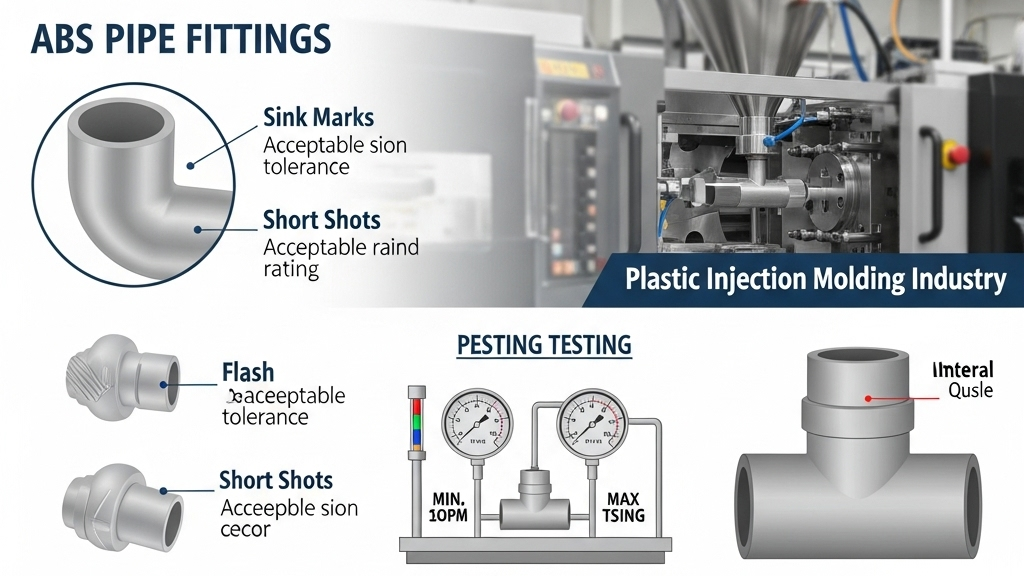

How to Address Common Issues in the Production of ABS Pipe Fittings?

During the production of ABS pipe fittings, common issues such as bubbles, deformation, and uneven color often arise, all of which can affect the product quality. By continually optimizing the production process, these common problems can be effectively minimized.

- Bubble Issues: Adjusting injection temperature and pressure helps reduce the formation of bubbles.

- Deformation Issues: Optimizing the cooling system ensures uniform cooling of the pipe fitting in the mold.

- Uneven Color Issues: Ensuring uniform mixing of raw materials and optimizing the use of color masterbatches.

- Surface Defects: Controlling mold temperature and injection speed helps reduce surface defects.

Optimizing the production process consistently improves the pass rate of the product.

How to Verify Whether ABS Pipe Fittings Meet Quality Control Standards?

Verifying whether ABS pipe fittings meet quality control standards is a vital part of ensuring product quality. Through physical performance tests and visual inspections, the quality of the fittings can be thoroughly evaluated. Having a comprehensive testing process is an effective way to ensure product quality.

- Physical Performance Testing: This includes basic performance tests such as tensile, bending, and impact testing.

- Visual Inspections: Using manual or machine inspections to check for surface defects.

- Dimensional Measurement: Using precision instruments to measure the pipe fitting dimensions to ensure they meet tolerance requirements.

- Environmental Testing: Simulating various environmental conditions to ensure stability during actual use.

Through rigorous validation processes, we ensure each pipe fitting meets strict quality control standards.

ABS Pipe Fittings Quality Control Standard Comparison

|

Quality Standard |

Material Selection |

Injection Molding Process |

Dimensional Tolerance |

Surface Quality |

Bubble Control |

Deformation Control |

| Standard Requirements | Appropriate ABS Resin | Fine-tuned Control | ±0.1mm | No Defects | No Bubbles | No Deformation |

| Testing Methods | Tensile Testing | Temperature Control | Instrument Measurement | Manual Inspection | Pressure Adjustment | Cooling System |

| Qualification Criteria | Strength Pass | Process Pass | Tolerance Pass | Surface Flaw-Free | No Bubbles | No Deformation |

How Do Quality Control Standards Impact ABS Pipe Fittings Production Efficiency?

To ensure the stability and reliability of ABS pipe fittings in the market, we need to establish strict production processes based on quality control standards. These standards not only include material selection, process control, and more but also need to be updated and improved to meet market demands.

1.Material Selection: Choosing appropriate ABS material ensures product quality.

2.Process Optimization: Optimizing the injection molding process improves product consistency.

3.Testing Methods: Regular testing ensures pipe fittings’ performance stability.

4.Continuous Improvement: Constantly adjusting quality control standards based on market and production feedback.

Conclusion

In the production of ABS pipe fittings, establishing and implementing strict quality control standards and testing processes is key to improving product quality. By refining each step and verification process, production efficiency can be enhanced, and defects reduced. Ultimately, a rigorous quality control system will enhance the competitiveness of our products in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-01-2025