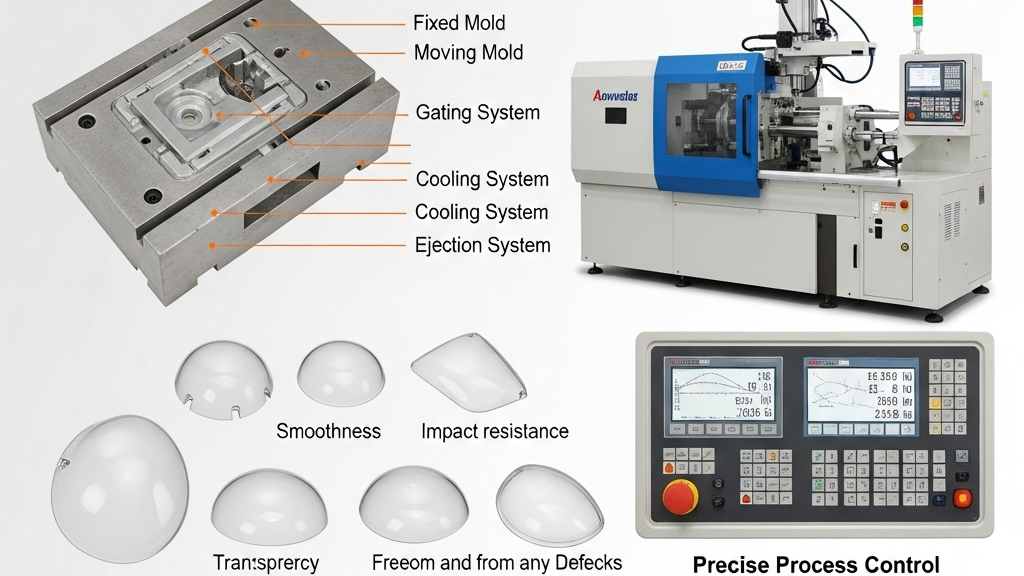

In optical applications, PC lenses are favored for their transparency and impact resistance. To meet diverse optical needs, custom mold development becomes essential. Custom tooling is the key to achieving precision in PC lens injection molding.

We continuously optimize mold structure, cooling, and runner layout to ensure optical quality and dimensional precision. Through comprehensive process control, we accelerate the transition from design to mass production.

How do we ensure optical precision in custom molds?

Optical standards require ultra-low surface roughness and micron-level tolerance. We use mirror polishing and high-precision machining to meet these demands.Steel selection directly impacts optical performance and mold longevity.

- Precision Design: CAE simulation for optimal optical flow path.

- Surface Finish: Mirror polishing and electroplating.

- Steel Selection: Low-deformation tool steel enhances wear resistance.

- Tight Tolerance: Machining controlled within ±0.005mm.

How to balance structural complexity and molding efficiency?

Multi-curve and varying thickness designs are common in PC lenses, demanding more from mold design. Modular inserts enable mass production for complex shapes.Modular mold design significantly reduces tooling changeover and testing time.

- Optimized Cooling System: Multi-point channels for uniform temperature control.

- Adjustable Parting Line: Better demolding and less stress.

- Quick Mold Change System: Enables rapid switching for multiple lens types.

- Insert Modules: Quick replacement for various shapes.

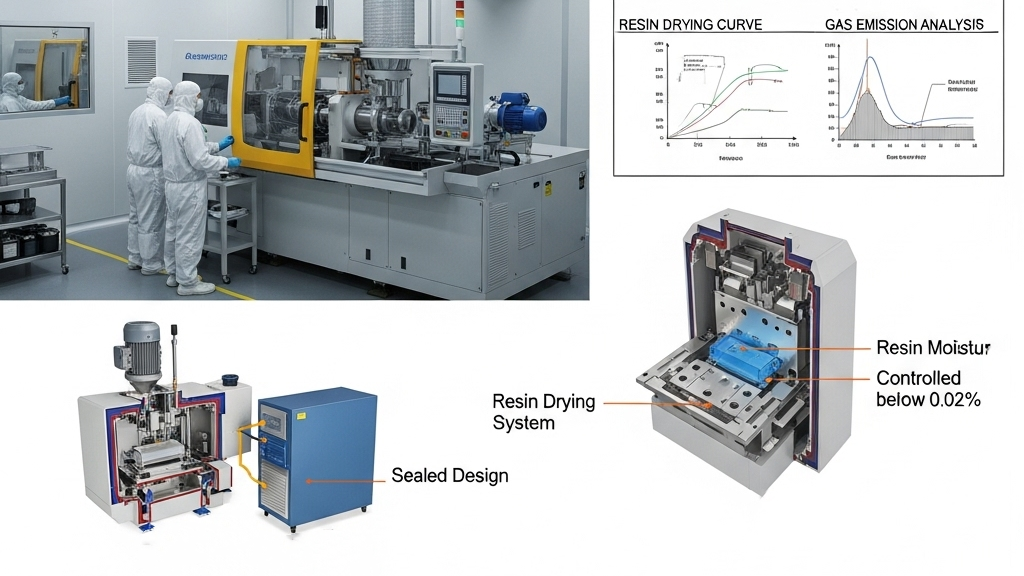

How do we ensure optical clarity during injection molding?

Impurities and particulates can reduce clarity. We ensure optical purity with cleanroom molding and controlled raw material handling.Clean molding environment is fundamental to achieving high light transmission.

- Clean Injection Machines: Oil-free systems prevent contamination.

- Resin Drying Control: ≤0.02% moisture via in-line drying.

- Gas Venting: Minimizes silver streaks and bubbles.

- Sealed Feeding System: Reduces secondary contamination.

Comparison of PC Lens Mold Options

|

Mold Type |

Accuracy |

Cycle Time |

Cost Level |

Cooling System |

Modularity |

Changeover Speed |

Surface Finish |

| Standard Mold | Medium | Moderate | Medium | Basic Channels | None | Regular | No Polishing |

| Optical Mold | High | Fast | High | Multi-Point | High | Fast | Mirror Polished |

| Insert-Based Mold | High | Moderate | Medium | Independent | High | Fast | Precision Coating |

| Fast Change Mold | Medium | Fast | Medium | General Use | Medium | Very Fast | Regular Finish |

Expansion

Our custom mold development covers the entire cycle from product review to trial production. By integrating process and mold development, we help clients launch faster.

1.Solution Review: Initial assessment of PC optical molding needs.

2.Collaborative Design: Simultaneous product & mold development.

3.Trial Molding Support: Multiple machines for rapid prototyping.

4.Delivery Control: Batch mold deliveries with lead time tracking.

Conclusion

Our service empowers the optical PC lens industry with high-precision, high-clarity, and high-stability molds.Fast response and optical compliance are key trends in mold customization.Choosing us means entering a collaborative, result-driven development path toward smarter, more efficient injection tooling.We will continue to innovate and deliver competitive mold solutions for the PC lens market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-12-2025