Introduction

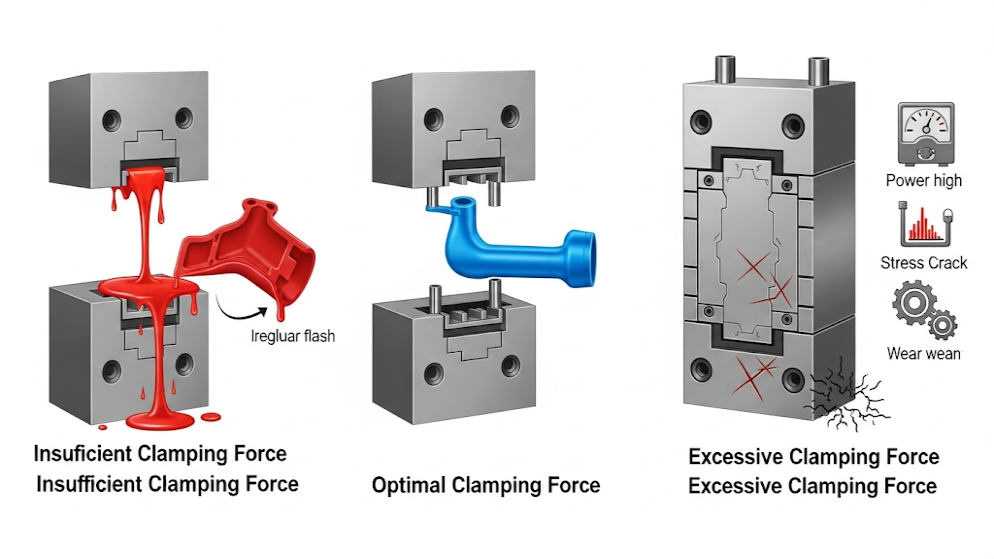

In injection molding, the setting of clamping force directly affects the molding quality and appearance of the product. If the clamping force is insufficient, the melt tends to flash at the parting line, leading to increased rework and scrap rates. Proper clamping force is the fundamental basis to ensure flash-free products.

At the same time, excessive clamping force not only increases machine energy consumption but also accelerates mold wear, reducing overall production efficiency. Scientific parameter setting ensures both product precision and extended equipment lifespan.

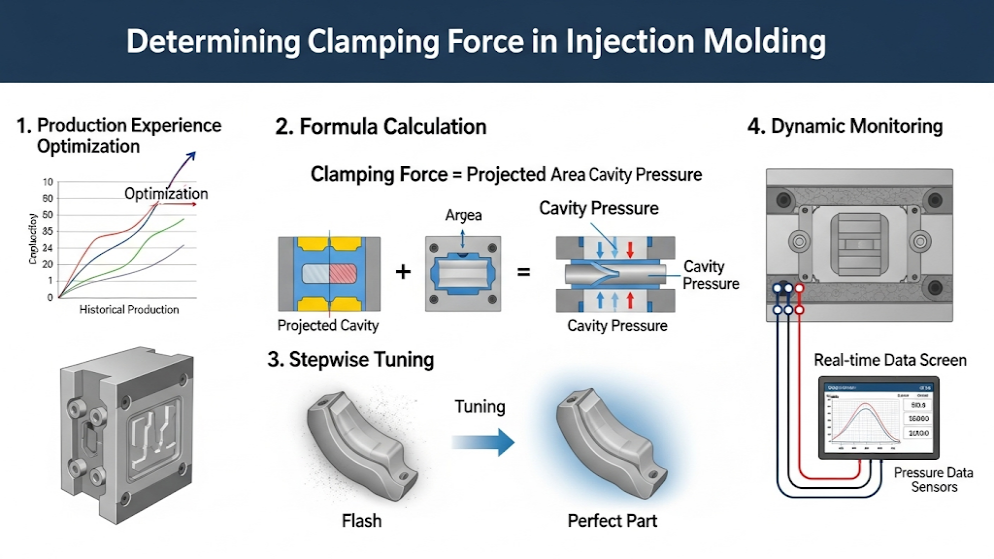

How to determine the right clamping force?

In actual production, the calculation of clamping force is based on the combination of projected area and cavity pressure. Too little force leads to melt leakage at the parting line, causing flash. Excessive clamping force, however, puts heavy load on the equipment and shortens mold life.

- Production Experience Optimization: Use past production data to set an initial value.

- Formula Calculation: Determine theoretical value by projected area × cavity pressure.

- Stepwise Tuning: Calibrate force gradually during mold trials.

- Dynamic Monitoring: Use pressure sensors for real-time control.

Accurate clamping force calculation ensures flash-free molding.

What problems does insufficient clamping force cause?

When clamping force is insufficient, the most common defect is flash, which severely affects appearance and assembly. Excess flash not only increases manual trimming costs but also weakens customer trust in product quality. In production, flash often becomes the hidden danger behind quality disputes.

- More Flash: Requires secondary trimming and increases process cost.

- Appearance Defects: Weakens market competitiveness and product value.

- Assembly Deviation: Flash interferes with accurate part fitting.

- Customer Complaints: Reduces satisfaction and repeat orders.

Insufficient clamping force lowers yield and increases after-sales risk.

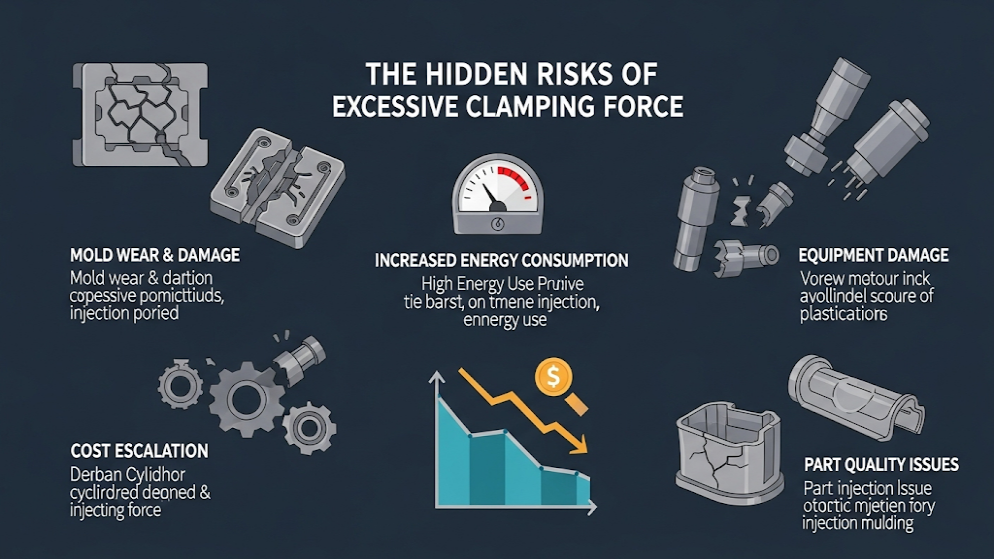

What hidden risks come with excessive clamping force?

Clamping force is not simply “the higher, the better.” Excessive force can damage the mold parting line and significantly increase energy consumption. Over time, this raises maintenance costs and shortens mold service life.

- Mold Wear: Excessive stress accelerates damage at parting surfaces.

- Higher Energy Use: Increased power consumption from machine load.

- Equipment Damage: Long-term high pressure strains hydraulic systems.

- Cost Escalation: Higher operating costs reduce profitability.

Proper clamping force balances production efficiency and operating cost.

Process Comparison of Clamping Force Settings

|

Setting Method |

Advantage |

Risk |

Application |

| Experience Set | Quick & easy | High deviation | Small batch |

| Formula-Based | Accurate | Ignores conditions | Mass production |

| Trial & Tuning | Practical | Time-consuming | New mold trial |

| Sensor Monitoring | Dynamic control | Higher cost | Precision molding |

How to reduce flash through process optimization?

Flash problems cannot be solved by clamping force alone—it requires coordination with melt temperature, injection speed, and mold precision. Only through synergy between clamping force and process parameters can true flash-free molding be achieved.

1.Optimize Temperature: Reduce over-fluidity of melt.

2.Adjust Speed: Avoid high-pressure impact on parting line.

3.Improve Mold Precision: Enhance sealing performance.

4.Better Venting: Prevent gas expansion that separates mold halves.

Conclusion

In injection molding, the reasonable setting of clamping force is crucial to avoiding flash while balancing efficiency and cost. Too low causes flash, too high damages molds and machines. Combining experience, formula-based calculation, and process optimization ensures both product quality and competitive production.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-27-2025