Polycarbonate (PC) has become the preferred material in lighting equipment due to its high transparency and excellent heat resistance. Injection molding allows it to combine complex structures with optical performance, achieving better light uniformity. It effectively reduces glare and hotspots, enhancing the user’s visual experience.

With precise mold design and process control, PC parts can deliver both superior diffusion and mechanical strength. This process not only boosts product quality but also offers greater design flexibility for manufacturers.

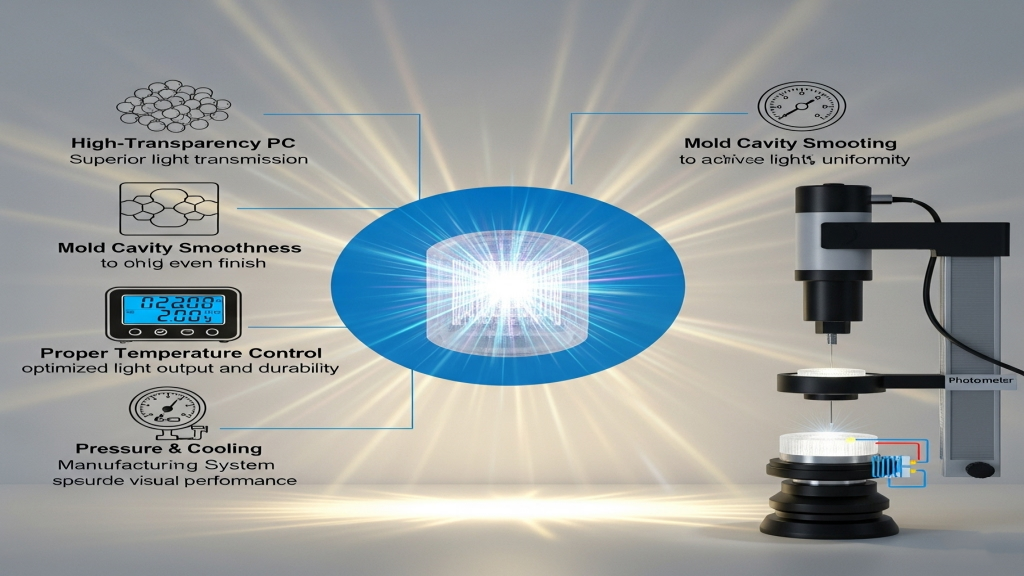

What factors affect the light uniformity of PC injection molding?

Light uniformity depends on material purity, mold design, injection pressure, and temperature control. Small variations in the process directly impact the diffusion behavior. High-standard process stability is key to consistent lighting performance.

- Material Selection: High-transparency PC improves light transmission.

- Mold Surface Polish: Mold cavity smoothness affects light uniformity.

- Temperature Control: Proper control prevents degradation.

- Pressure & Cooling: Influences density and optical quality.

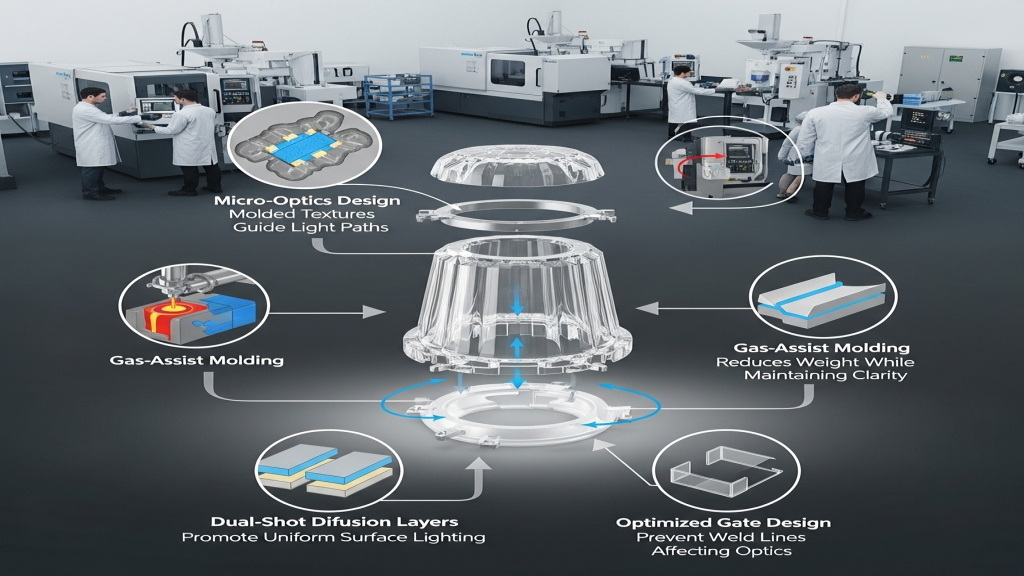

How can injection molding enhance optical performance?

Techniques such as microstructure design, gas-assist molding, and dual-shot molding help control light spread and diffusion angle. These processes maximize optical consistency and overall lighting quality.

- Micro-Optics Design: Molded textures guide light paths.

- Gas-Assist Molding: Reduces weight while maintaining clarity.

- Dual-shot Diffusion Layers: Promote uniform surface lighting.

- Optimized Gate Design: Prevent weld lines affecting optics.

Why is haze control important in PC molded optics?

Light diffusion quality affects visual comfort in real use. PC molding parameters determine haze level. Proper haze management creates softer and glare-free illumination.

- Surface Texture Tuning: Affects light scattering quality.

- Diffuser Additives: Microparticles disperse light inside the polymer.

- Temperature Control: Prevents bubbles and artifacts.

- Mold Cooling Strategy: Balances shrinkage and haze.

Comparison of Haze Control in Optical Molding

|

Control Method |

Process Difficulty |

Cost |

Cycle Time |

Light Diffusion |

Stability |

Scalability |

Application |

| Mold Texturing | Medium | Mid | Medium | Strong | High | High | General |

| Diffusing Additives | Low | Low | Fast | Moderate | Medium | High | Basic Use |

| Haze Coating | High | High | Slow | Strong | Medium | Low | Premium |

| Dual-shot Molding | High | High | Medium | Strong | High | Medium | Smart Tech |

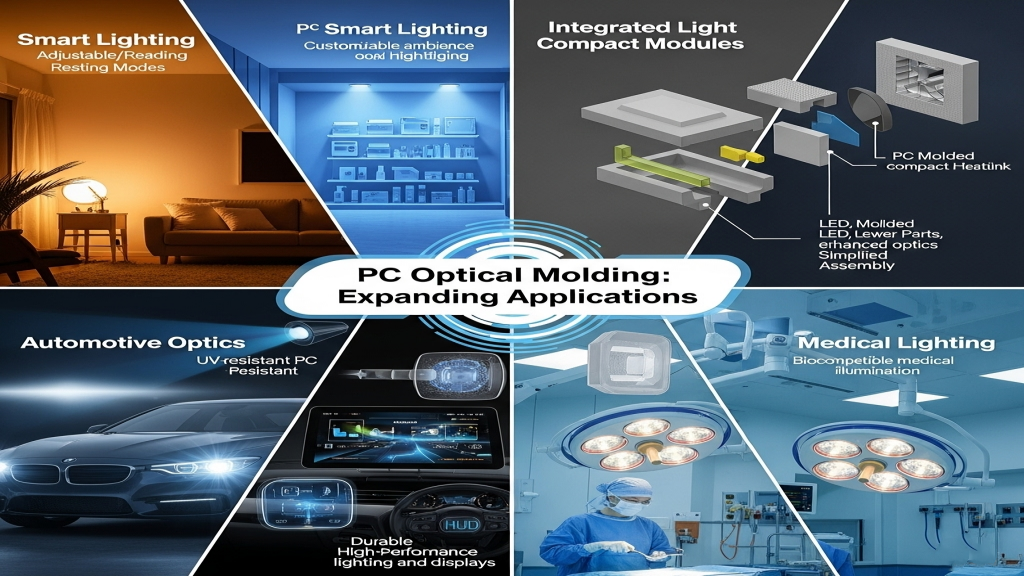

Expansion

PC optical molding is expanding into smart lighting, automotive optics, and medical light-guiding systems. It enables integrated light diffusion and mechanical structure for next-gen product designs.

1.Smart Light Customization: Scene-specific brightness and beam shapes.

2.Integrated Light Modules: Fewer parts, better optics.

3.Automotive Optics Trends: UV-resistant, high-bright PC molding.

4.Medical Lighting: Soft, accurate illumination for procedures.

Conclusion

With superior optics and process control, PC injection molding offers a pathway to softer and more uniform light output. Amid growing demand for efficient and eye-friendly lighting, its adaptability and technical value continue to rise. Custom injection strategies help companies boost product innovation and accelerate time-to-market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-03-2025