Introduction

CNC drilling and tapping play a crucial role in modern manufacturing, especially in applications requiring extremely tight tolerances. Our equipment supports multi-axis synchronization, enabling micron-level precision. The alignment between tapping and drilling is nearly flawless, forming the foundation of our consistent quality.

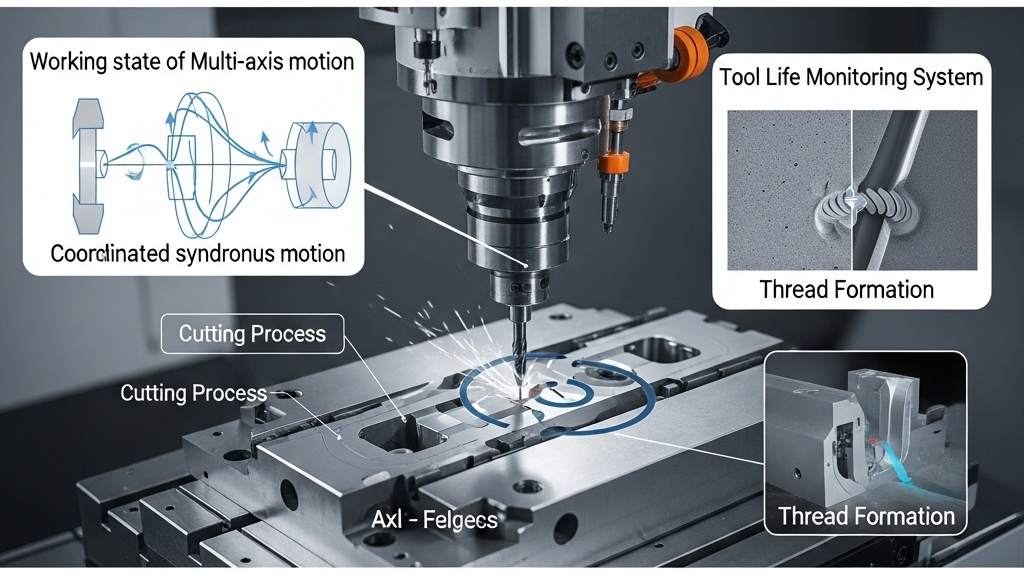

Precision comes not only from hardware but also from process control and operational experience. We utilize tool life monitoring systems to ensure hole repeatability. Paired with real-time data feedback, we continuously optimize feed-in and withdrawal parameters.

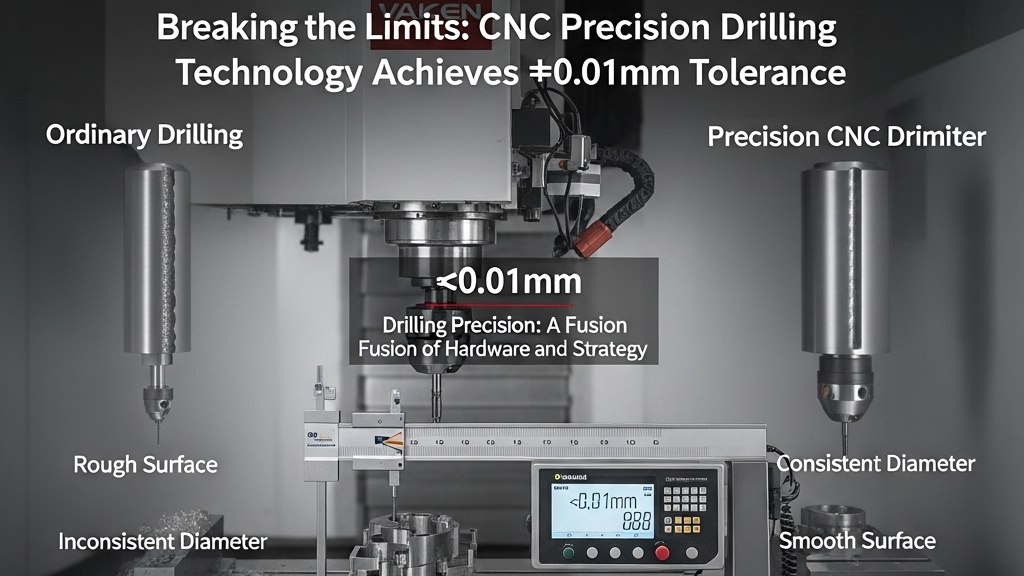

How precise can CNC drilling be?

Drilling accuracy is not only about position but also about diameter consistency and surface smoothness. All our machines are equipped with high-precision spindles and cooling systems to prevent thermal deformation during long runs. In aerospace and medical components, our drilling tolerance reaches ±0.01mm.

- Hole Position Accuracy: Auto-compensation systems correct deviations in real time.

- Spindle Rigidity Assurance: High-rigidity spindles maintain consistent RPM and torque.

- Tool Cooling Management: Temperature-controlled liquid cooling reduces heat diffusion.

- Bore Consistency Optimization: Tool wear and performance are dynamically monitored.

The essence of drilling precision lies in a fusion of hardware and strategy.

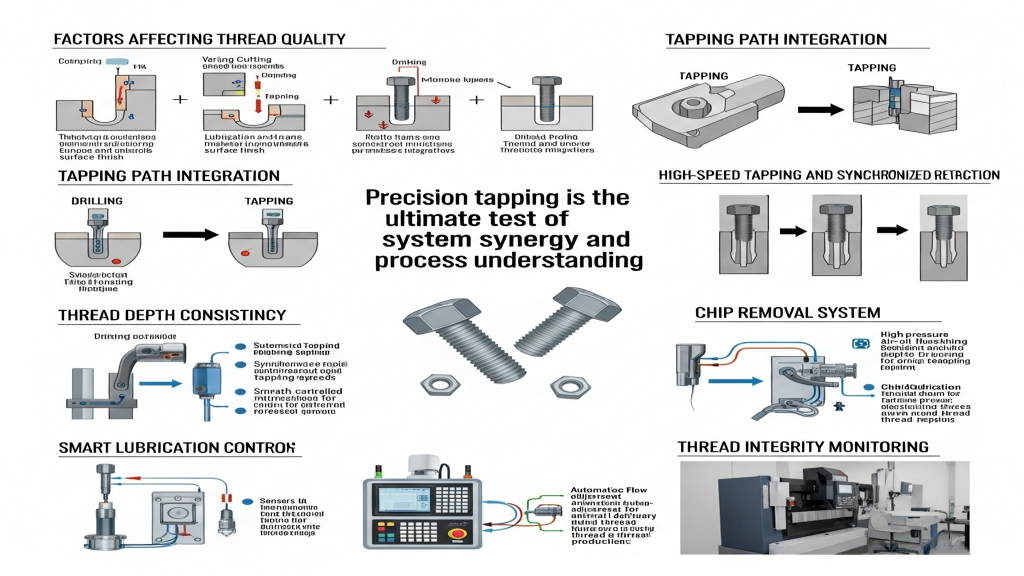

How do we ensure tapping thread consistency?

Thread quality depends on factors like cutting speed, lubrication, and material. We integrate the tapping path directly into the drilling process in our programming to ensure uniformity. With high-speed tapping and synchronized retraction, we guarantee clean threads without edge cracks.

- Thread Depth Consistency: Controlled tapping depth with auto-feedback.

- Chip Removal System: High-pressure air-oil flush clears debris efficiently.

- Smart Lubrication Control: Lubrication flow adjusts automatically by material.

- Thread Integrity Monitoring: Post-process inspection ensures no tooth defects.

Precision tapping is the ultimate test of system synergy and process understanding.

How do we position micro-holes with multi-axis systems?

For micro-holes, especially on complex parts, multi-axis coordination is key. Our zero-point correction and coordinate transformation techniques significantly improve positional repeatability. Hole positioning errors are controlled within ±0.005mm—even under high-speed dynamic movement.

- 5-Axis Micro Drilling: Suited for all-angle micro-holes on irregular parts.

- Zero-Point Calibration: Auto-detects references to enhance accuracy.

- Profile Error Management: Simulated paths reduce trajectory deviation.

- High-Sensitivity Probes: Detect and correct pre/post-process deviations.

Drilling micro-holes isn’t about luck—it’s precise, calculated execution.

Performance Comparison of CNC Drilling and Tapping Equipment

|

Feature |

High-Speed CNC |

5-Axis CNC |

Standard 3-Axis |

Manual Tapping |

| Hole Accuracy | ±0.01mm | ±0.005mm | ±0.05mm | ±0.2mm |

| Thread Consistency | Very High | Very High | Medium | Low |

| Micro-Hole Capability | Strong | Excellent | Weak | None |

| Tool Cooling Control | Yes | Yes | Limited | None |

How Do We Integrate Multiple Machining Strategies?

We follow an integrated process-standard-equipment model to ensure cohesion. Each stage is pre-designed with holes, threads, materials, and post-treatment in mind—avoiding rework and error accumulation.Integration isn’t just stitching steps; it’s understanding interference and workflow logic. We use a CAD/CAM unified platform to keep every link under digital control.

1.Multi-Process Fusion: Drilling, tapping, chamfering completed in one go.

2.Auto Tool Library Sync: Reduces tool change time and boosts efficiency.

3.Digital Simulation: Simulates sequence and interference in virtual space.

4.Intelligent Parameter Deployment: Each step runs with optimal parameters.

Conclusion

By combining high-precision CNC drilling and tapping, we meet the ultra-tight tolerance needs of medical, aerospace, and precision electronics industries. Whether it’s hole position, threads, or geometric fit—we ensure consistency and repeatability. Beyond machines, we focus on how each process influences the final result for complete quality assurance.Precision manufacturing is not about equipment alone—it’s about integrated system harmony.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-28-2025