5-axis CNC technology has become essential in modern manufacturing for handling complex surfaces, especially in high-precision countersinking. This demand is rising in sectors like aerospace and high-end tooling. Accurate positioning on complex surfaces far exceeds the requirements of standard flat surface machining.

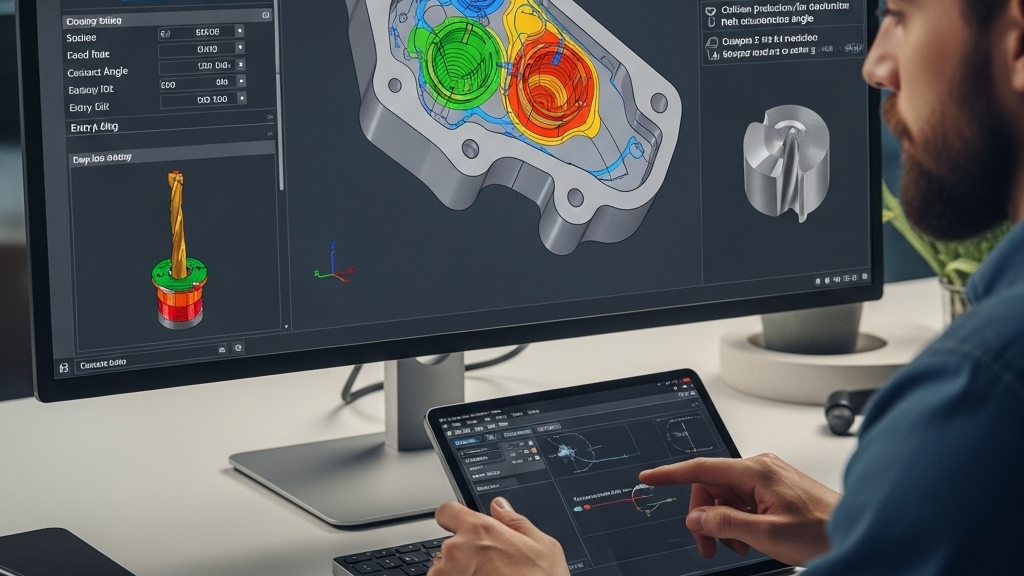

To overcome these challenges, manufacturers are integrating high-performance software and automation systems. Multi-axis control and dynamic tool compensation are becoming industry standards. Balancing high precision and efficiency is the development direction of 5-axis CNC.

How does 5-axis CNC handle countersink positioning errors?

Irregular 3D geometries make traditional positioning ineffective for precision machining. The flexibility of 5-axis motion provides multi-angle entry points, allowing closer-to-ideal access. With accurate CAM simulation, path deviations can be predicted and corrected effectively.

- Multi-angle fixturing: Increases positioning stability.

- Laser or probe calibration: Improves initial zero-point accuracy.

- Optimized CAM paths: Identifies collisions before they occur.

- Live tool offset correction: Dynamically eliminates displacement errors.

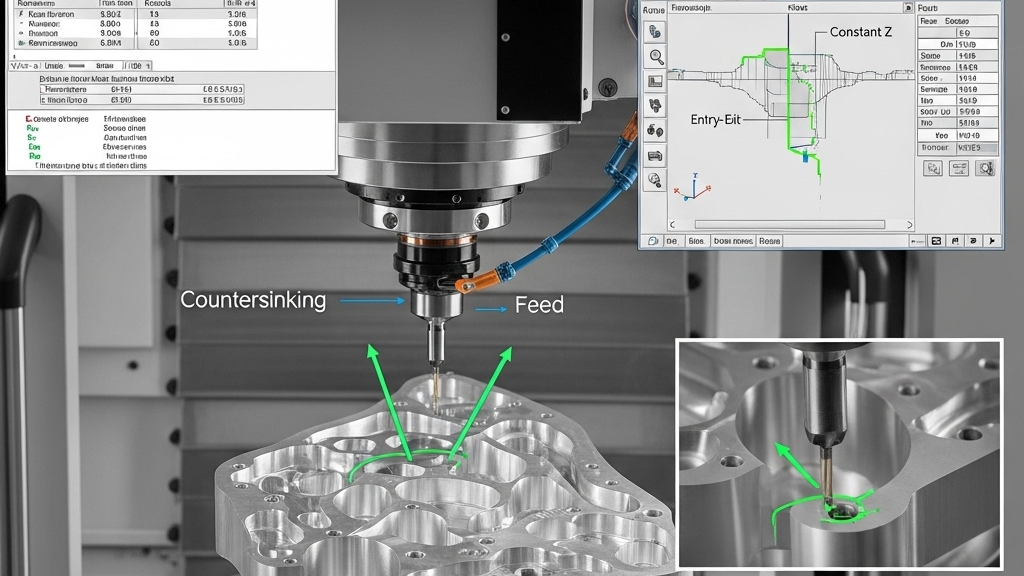

How to plan toolpaths for irregular surfaces?

When working on irregular surfaces, contact angles, depth, and entry-exit vectors are critical. The path not only affects surface quality but also determines the uniformity of the countersink. Avoiding overlap or deflection is key to maintaining hole consistency.

- Use constant-Z strategies: Ensures uniform cutting.

- Maintain vertical tool entry: Minimizes burrs and distortion.

- Simulate to prevent interference: Enhances operational safety.

- Use short overhang tools: Increases structural rigidity.

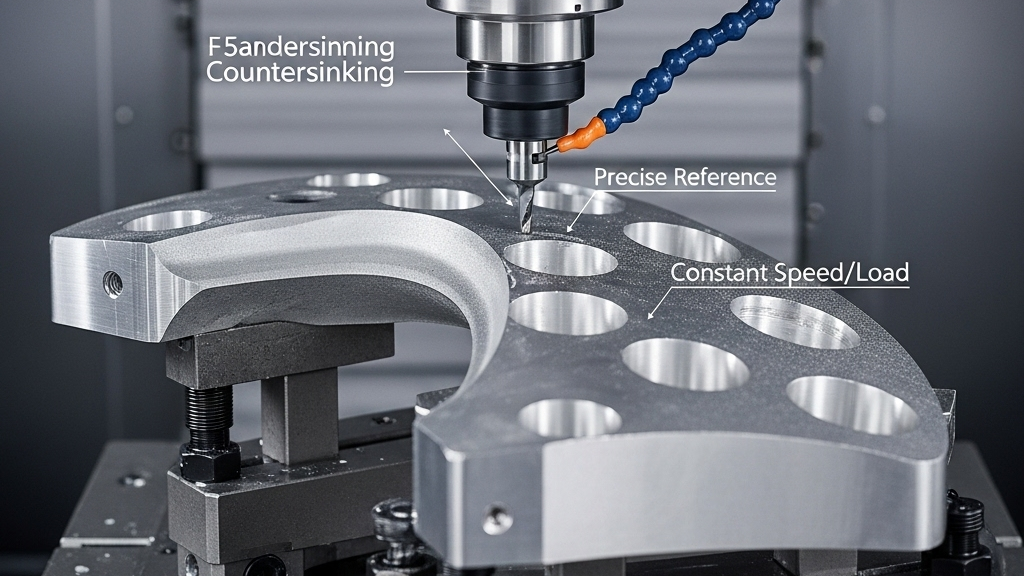

How to control surface errors and avoid hole distortion?

Complex surfaces are prone to vibration and thermal deformation, causing hole contour errors. Adjusting cutting parameters and using stable fixtures can significantly reduce error propagation. Minor surface ripples may magnify into notable deviations in hole roundness.

- Constant speed/load strategy: Stabilizes material removal rate.

- High-accuracy reference transfer: Reduces source propagation.

- Thermal deformation suppression: Controls environmental impact.

- Finishing pass with fine tools: Guarantees roundness.

Comparison of Common 5-Axis Countersink Methods

|

Item |

High-Speed Milling |

Mirror Finishing |

Multi-Axis Drilling |

EDM Assisted |

| Accuracy Level | ★★★ | ★★★★ | ★★ | ★★★ |

| Cost | Medium | High | Low | High |

| Time | Fast | Slow | Fast | Slow |

| Application | Wide | Narrow | Wide | Niche |

| Surface Finish | Medium | High | Low | Medium |

| Programming | Medium | High | Low | High |

| Equipment | Standard 5-Axis | Precision 5-Axis | Regular 5-Axis | Special EDM |

| Best Use | General Machining | Aesthetic Surfaces | Batch Holes | Ultra-Fine Holes |

How Enhances 5-Axis Countersinking

Automated metrology and digital twin modeling are revitalizing 5-axis processing. Closed-loop feedback links modeling, simulation, and machining seamlessly. Smart compensation systems significantly lower error rates and improve overall yield.

1.AI Parameter Recognition: Auto-tunes feed and spindle speeds.

2.Digital Twin Modeling: Prevents interference pre-production.

3.Closed-Loop Control: Enables adaptive correction.

4.Remote Job Scheduling: Accelerates multi-part workflow.

Conclusion

5-axis CNC showcases unique flexibility and high accuracy in countersinking complex surfaces. Proper toolpath design and strict error control allow manufacturers to meet multidimensional machining challenges. Adopting smart tools is essential for boosting countersink yield. As CAM algorithms and automation evolve, 5-axis CNC will further unlock process potential.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: May-27-2025