Introduction

Anodizing is often regarded as a process exclusive to metal surfaces, but with the advancement of plastic injection molding, similar metallic effects can now be achieved through surface texturing and coating systems. This technology allows plastic parts to visually and functionally match aluminum components.

In automotive interiors, consumer electronics, and lighting housings, plastic parts simulating anodized finishes are increasingly popular. They offer cost reduction while maintaining flexible design and scalability. This is not just a surface innovation — it’s a commercial breakthrough in the injection molding industry.

How can injection molding achieve an anodized-like appearance?

The visual texture of anodizing can be reproduced through specialized mold surface textures, coating formulations, and post-processing techniques. Accurate replication of microstructures is the key to creating metallic reflections on plastic surfaces. Additionally, control over molding temperature and cooling rates determines the coating adhesion and gloss stability.

- Microtexture Mold Design: Achieved by EDM or laser engraving to replicate metallic reflection.

- Metalized Coating Process: Vacuum plating or PVD to enhance metallic luster.

- High-Temperature Injection Optimization: Fine-tuning melt temperature ensures smooth and shiny surfaces.

- Eco-Friendly Coating Alternatives: Water-based silver coatings for reduced VOC emissions.

The secret to achieving metallic aesthetics lies in the harmony between mold and process precision.

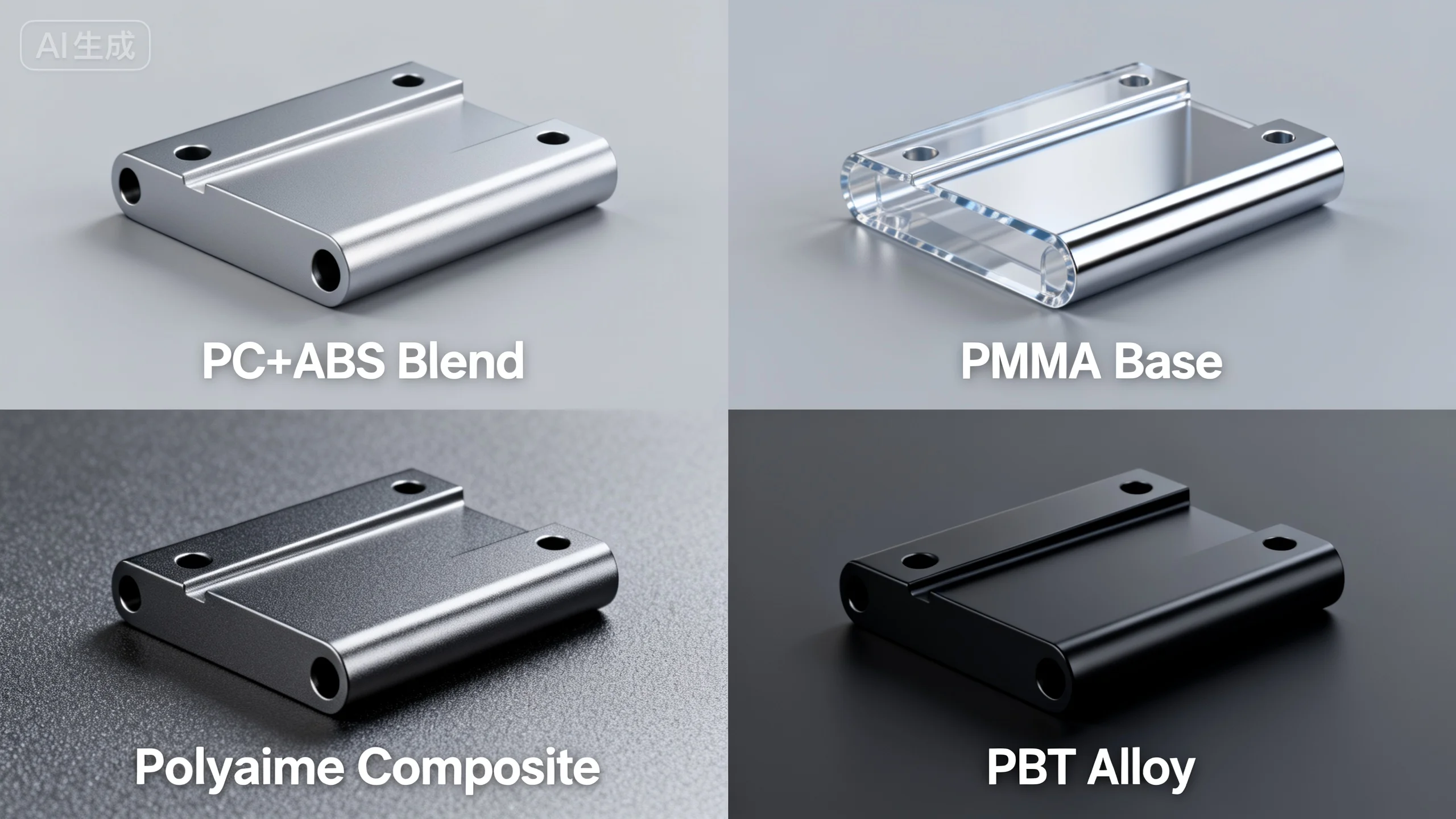

Which materials are best for anodized simulation?

Material selection directly affects coating adhesion and reflective performance. PC, ABS, and PMMA blends are widely used for plastic parts simulating anodized effects. These materials exhibit excellent optical clarity and thermal stability, ensuring strong bonding with post-coating layers.

- PC+ABS Blends: Combine strength and surface activity for better coating adhesion.

- PMMA Base: Excellent transparency and smooth surface for metallic gloss.

- Polyamide Composites: Improved rigidity and heat resistance.

- Modified PP: More cost-effective, suitable for mid-range decorative parts.

Material choice defines the realism and durability of anodized finishes.

How can plastic surfaces enhance the durability of anodized textures?

Even when the appearance matches metal, the surface durability and UV resistance of plastics must be improved. Using dual-layer coating systems or nano-enhanced paints is the main approach to strengthen surface endurance. Additionally, surface energy treatment enhances scratch resistance and maintains gloss during long-term use.

- Nano-Enhanced Coating: Increases scratch and corrosion resistance.

- UV-Cured Protective Layer: Guards against UV aging and fading.

- Ion Plating Base Layer: Enhances coating adhesion.

- Plasma Surface Pre-Treatment: Improves surface energy for better bonding.

Anodized aesthetics are not just visual art—they’re material engineering in action.

Plastic Solutions for Simulated Anodizing

|

Material System |

Surface Process |

Durability |

Cost |

Realism |

Eco-Friendliness |

Application |

| PC+ABS | Vacuum Plating + Spray | ★★★★☆ | ★★★ | ★★★★★ | ★★★ | Automotive Trim |

| PMMA | PVD Coating | ★★★★ | ★★★★ | ★★★★☆ | ★★★★ | Consumer Electronics |

| Modified PP | Electroplated Spray | ★★★ | ★★☆ | ★★★ | ★★★ | Appliance Housings |

| PA Composite | Nano Coating | ★★★★★ | ★★★★ | ★★★★ | ★★★★☆ | Industrial Components |

Want to create metallic realism for your injection projects? contact us now to explore custom anodized solutions!

Industrial Applications of Anodized Effects

Anodized-look plastics bring not only aesthetic innovation but also cost-effective manufacturing benefits. Their wide application across automotive, electronics, and architectural sectors is driving the replacement of metal components. By combining intelligent mold design with advanced surface engineering, manufacturers can flexibly control color, gloss, and tactile feel.

1.Automotive Interiors: Replace aluminum trims to reduce weight.

2.Electronic Housings: Enhance metallic texture and user experience.

3.Architectural Components: Offer both decorative and weather-resistant performance.

4.Lighting Modules: Ensure uniform reflection and soft visual tone.

Conclusion

Simulating anodized finishes through injection molding represents a perfect balance between material innovation and visual design. It delivers energy-efficient, flexible, and high-quality alternatives to metal components. With precise material selection, coating technology, and process optimization, plastics can perfectly reproduce metallic aesthetics.Looking forward, this technology will play a key role in lightweight automotive design and sustainable manufacturing, helping companies stand out in the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-11-2025