Introduction

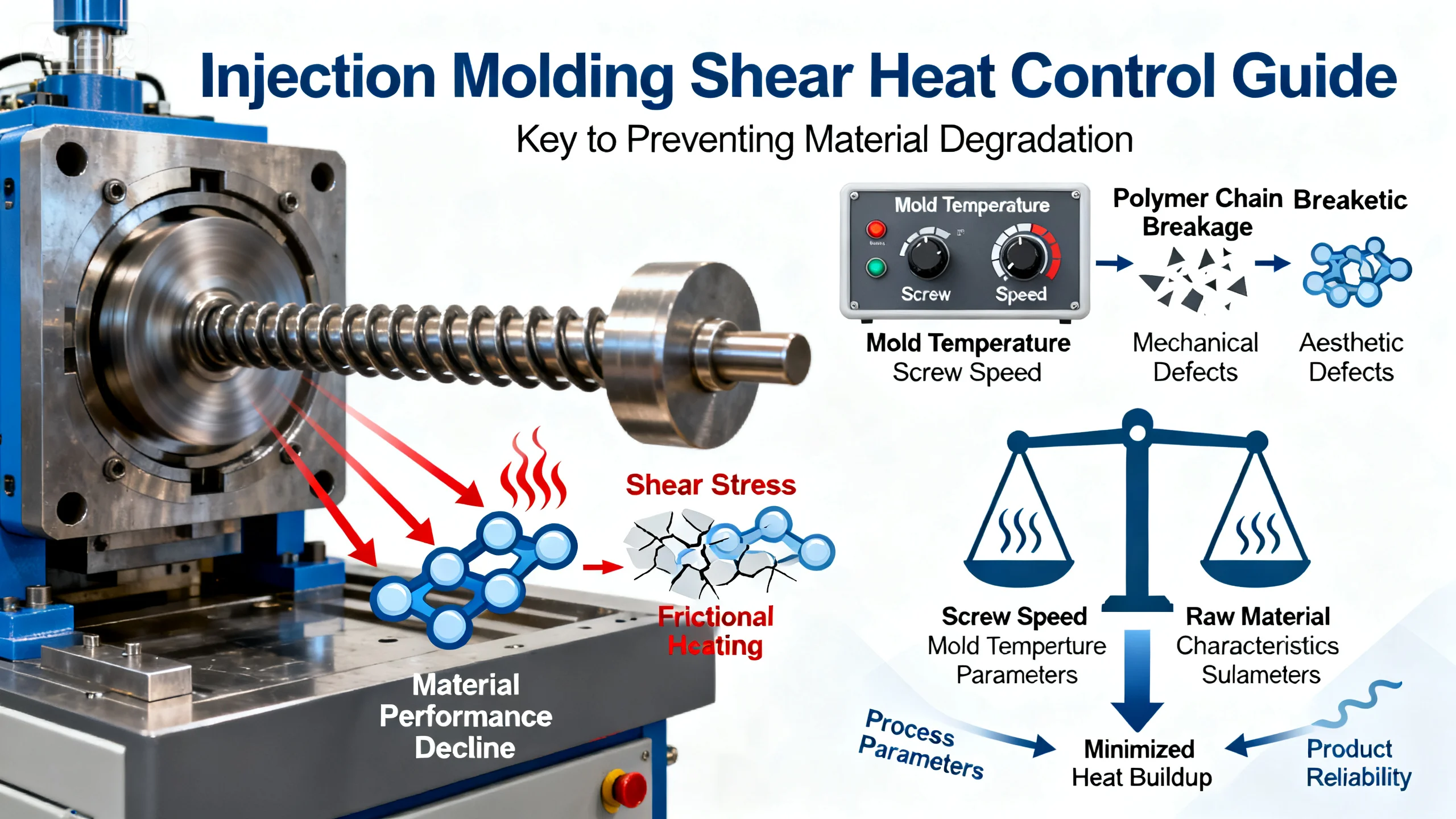

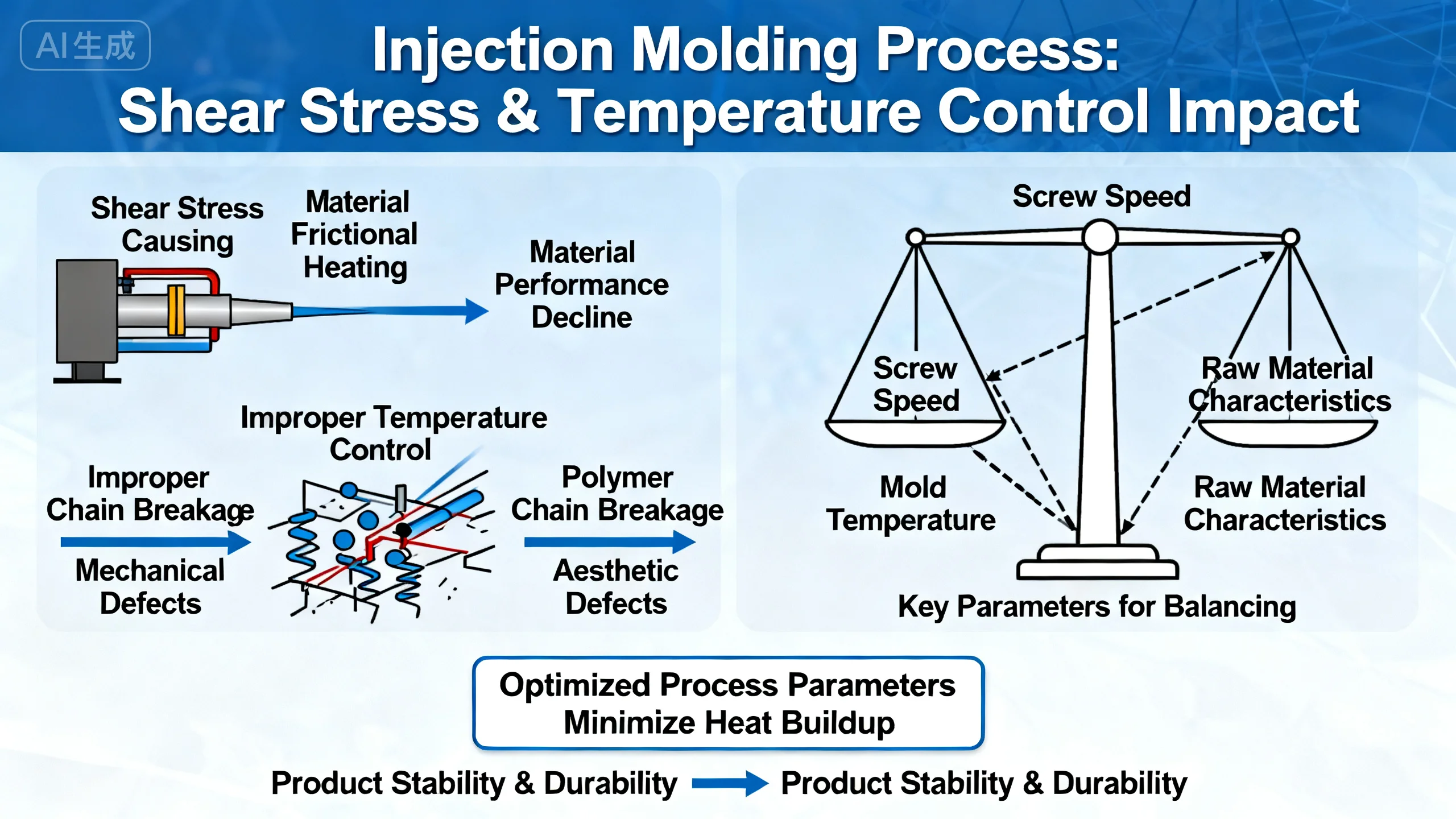

During injection molding, excessive shear stress can cause frictional heating, leading to a decline in material performance. Improper temperature control can break polymer chains, resulting in both mechanical and aesthetic defects. Controlling shear heat is directly linked to product stability and durability.

To maintain the polymer’s molecular structure during molding, it is essential to balance screw speed, mold temperature, and raw material characteristics. With optimized process parameters, heat buildup can be minimized, ensuring efficiency and product reliability. Accurate temperature management is the key to preventing material degradation.

How can process parameters be adjusted to reduce shear heat?

In injection molding, excessive screw rotation speed and injection velocity significantly increase shear heat. Proper parameter control ensures uniform plasticization, preventing overheating and oxidation. Reducing mechanical friction and optimizing flow channels are effective ways to limit heat buildup.

- Optimize Screw Speed: Keep within a safe range to reduce mechanical friction.

- Control Back Pressure: Stabilizes melt flow and prevents sudden temperature spikes.

- Improve Flow Channel Design: Smooth runner sections help reduce local shear.

- Minimize Residence Time: Shorter heating cycles prevent thermal aging.

Optimized process settings effectively reduce shear heat and prevent premature material aging.

How can equipment design help minimize shear heat impact?

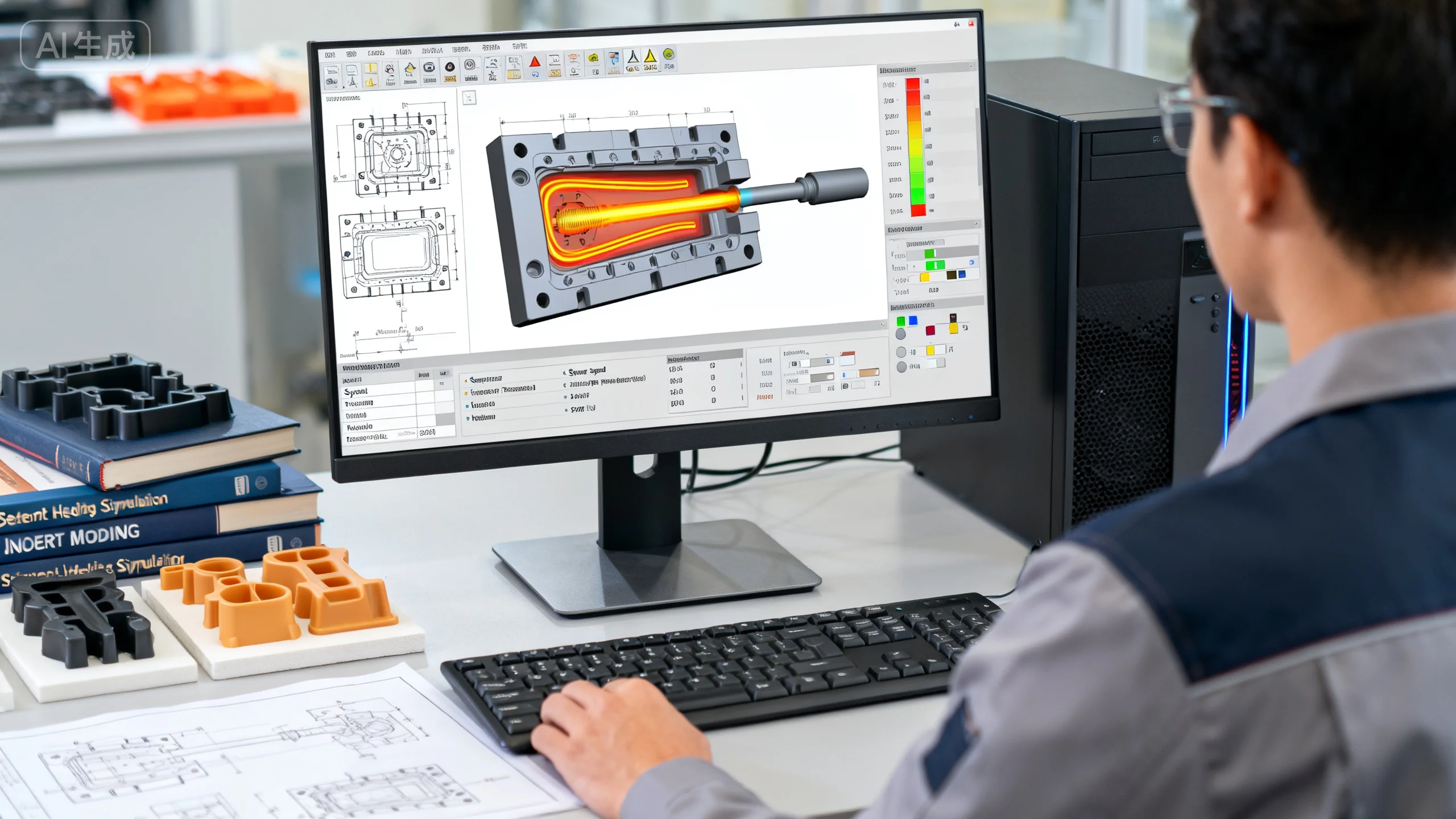

Equipment design plays a crucial role in temperature control. Screw geometry, barrel heating zones, and cooling systems all determine how uniformly the melt is heated. Using zoned temperature control and high-efficiency cooling minimizes thermal concentration risks.

- Improve Screw Design: Low-shear sections help reduce frictional heat.

- Upgrade Cooling Systems: Efficient water-cooling enhances thermal balance.

- Use Wear-Resistant Materials: Minimizes frictional heat and extends screw life.

- Implement Multi-Zone Temperature Control: Enables precise heating management.

Equipment optimization ensures stable molding and prevents localized thermal degradation.

How can material and additive selection resist shear heat degradation?

Beyond process and equipment optimization, material selection is equally vital. Choosing polymers with high thermal stability and incorporating antioxidants can prolong material lifespan under shear stress. Material modification is an effective defense against thermal stress and molecular chain breakage.

- Add Antioxidants: Prevents chain scission caused by heat and oxidation.

- Use High-Temperature-Resistant Resins: PPS, PEEK, and similar polymers show superior heat stability.

- Apply Heat-Stabilizing Coatings: Enhances resistance to thermal aging.

- Use Low-Friction Fillers: Improves flowability and reduces shear heating.

The right formulation and additive combination greatly enhances thermal stability and reduces degradation risk.

Comparison of Shear Control Strategies

|

Control Type |

Main Approach |

Effectiveness |

Suitable Materials |

Degradation Risk |

Cost |

Feasibility |

| Process Control | Adjust speed and pressure | Medium | General plastics | Medium | Low | High |

| Equipment Optimization | Zoned heating, advanced cooling | High | Engineering plastics | Low | Medium | Medium |

| Material Modification | Additives and high-heat polymers | High | Specialty plastics | Low | High | Medium |

| Mold Design | Balanced runners, polished surfaces | Medium | General plastics | Medium | Medium | High |

Want to enhance molding stability further? Learn more by contact us.

How to Monitor Shear Heat in Real Time on Production Lines?

Using temperature sensors and intelligent control systems enables real-time tracking of shear heat. Automated systems can adjust screw speed and back pressure dynamically, keeping the melt in an optimal temperature range. Smart monitoring not only prevents degradation but also optimizes energy use and production balance.

1.Install Thermocouple Networks: Monitor barrel and mold temperature at multiple points.

2.Use AI Predictive Algorithms: Detect abnormal temperature patterns early.

3.Adopt Closed-Loop Control Systems: Automatically adjust speed and temperature.

4.Build Process Databases: Record and analyze each batch for improvement.

Conclusion

Managing shear heat is not only a technical requirement but also a cornerstone of consistent injection molding quality. With a coordinated approach combining process control, equipment design, and material selection, polymer degradation can be effectively prevented. Comprehensive temperature control ensures reliable, high-performance molded parts.

For expert assistance in implementing precision temperature management for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-09-2025