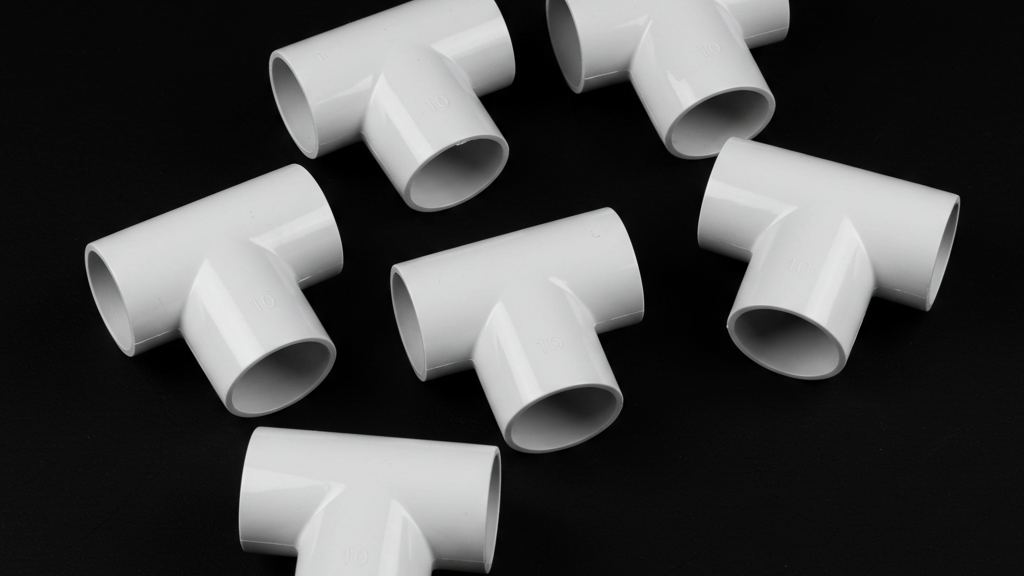

PC and TPU are widely used due to their excellent properties, but the warpage problem of injection molding is common. This defect affects product quality and assembly. It is important to understand the warpage mechanism and master the control methods.

We will discuss strategies for mold design, process parameter optimization, material selection, and post-processing. By applying these methods together, the occurrence of warpage can be significantly reduced.

What is the root cause of warpage deformation?

Warpage is like an “invisible killer” of injection molded parts, which silently changes the shape and size of the product. Exploring the root cause is like looking for the root cause of a disease, and only by finding the cause can we prescribe the right medicine and solve the problem completely.

- Uneven shrinkage: The difference in cooling rate of each part of the injection molded part leads to inconsistent shrinkage and internal stress.

- Residual Stress: The pressure and shear forces generated during the injection molding process create uneven residual stresses inside the injection molded part.

- Mold design: Unreasonable mold design affects cooling and shrinkage, resulting in warpage.

- Material properties: The crystallinity and thermal expansion coefficient of the material affect the degree of warpage and deformation.

What are the key factors that affect warping?

From mold design to process parameters to material selection, every step can have a profound impact on warpage. Understanding these key factors is like having a “baton” in our hands, allowing us to navigate injection molding production and effectively control warpage.

- Material properties: The inherent properties of the material, such as shrinkage, coefficient of thermal expansion, and water content, directly affect the deformation tendency of the injection molded part.

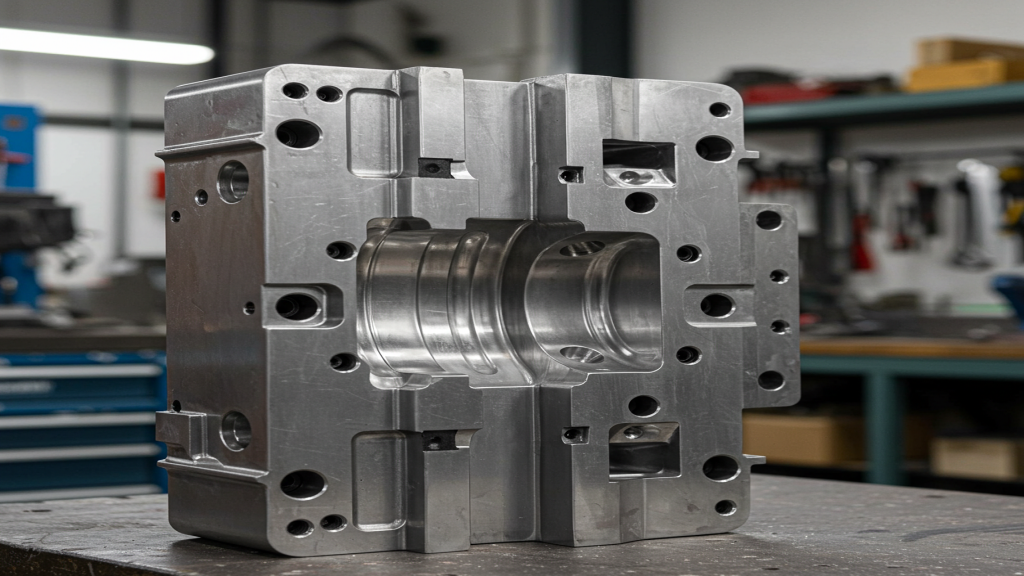

- Mold design: Design details such as the gating system, cooling system, and mold structure determine the flow and cooling uniformity of the molten plastic, which affects the warpage.

- Injection molding process parameters: The setting of process parameters such as injection temperature, pressure, speed, holding pressure and cooling time directly affects the flow state and internal stress distribution of the material.

- Post-treatment: Subsequent treatments such as annealing, fixture correction and surface coating can help eliminate residual stresses and restore the shape of the product.

What role does material selection and post-processing play in controlling warpage deformation?

The control of warpage deformation not only depends on precise mold design and strict process parameters, but also material selection and post-processing.

- Material property influence: By selecting a material with the right shrinkage and coefficient of thermal expansion, the possibility of warpage is reduced at the source.

- Material modification: Optimize material properties by enhancing material rigidity and flowability, further reducing the risk of warpage.

- Eliminate internal stress: Use post-treatment methods such as annealing to release the residual stress inside the injection molded part and effectively reduce the deformation.

- Correction of deformation: Correction of fixtures and other methods is used to physically correct the warpage deformation that has occurred and restore the size of the product.

Table of deformation control factors of injection molded parts

|

Control Factors |

Key Influences |

Specific Measures |

Effectiveness Evaluation |

| Material Selection | Shrinkage rate, coefficient of thermal expansion, hygroscopicity | Select low shrinkage rate materials, material modification (reinforcement), drying treatment | Reduced warpage deformation, improved dimensional stability |

| Mold Design | Gating system, cooling system, mold structure | Reasonably design gate position and size, optimize cooling water channels, improve mold structure | Uniform melt flow, uniform cooling, reduced demolding deformation |

| Injection Molding Process | Injection temperature, pressure, speed, holding pressure, cooling | Optimize injection parameters, reasonably set holding pressure and cooling time | Reduced residual stress, uniform shrinkage, improved product quality |

| Post-processing | Residual stress, deformation correction | Annealing treatment, fixture correction, surface coating | Eliminate internal stress, restore product shape, improve appearance |

A solution for controlling warpage and deformation of injection molded parts

Controlling the warpage and deformation of injection molded parts is a systematic project, which requires comprehensive consideration of multiple factors such as materials, molds, processes and post-processing. In actual production, a reasonable control plan should be formulated according to the specific situation, and constantly optimized and adjusted to achieve the best results.

1.Material selection and handling: By selecting the right material and carrying out the necessary treatment, the possibility of warpage deformation is reduced at the source.

2.Mold Design Optimization: Optimize the mold structure and system to ensure uniform flow and cooling of molten plastics, and reduce internal stress.

3.Injection molding process parameter control: Finely adjust the process parameters to control the material flow state and cooling process to avoid uneven shrinkage.

4.Post-processing: Eliminate residual stresses and restore or improve the shape of injection molded parts by means of annealing or fixture correction.

conclusion

The integrated control strategy is the key, and the effect of a single optimization is limited. Material selection, process optimization, and post-processing need to work in synergy. In the production process, continuous optimization and improvement should be made to improve product quality. Data analysis and experimental validation help to refine the control strategy.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-19-2025