Polycarbonate is widely used in high-performance injection-molded parts for its high transparency and toughness. It is gaining attention for its reliability in electronics, automotive, and medical industries. Enhancing structural impact resistance is a critical challenge under complex impact environments.

In real-world applications, impact loads come from collision, drops, or assembly misalignment. Only by considering materials, structures, and processes can we maximize performance. Preventive design saves cost more effectively than post-failure repairs.

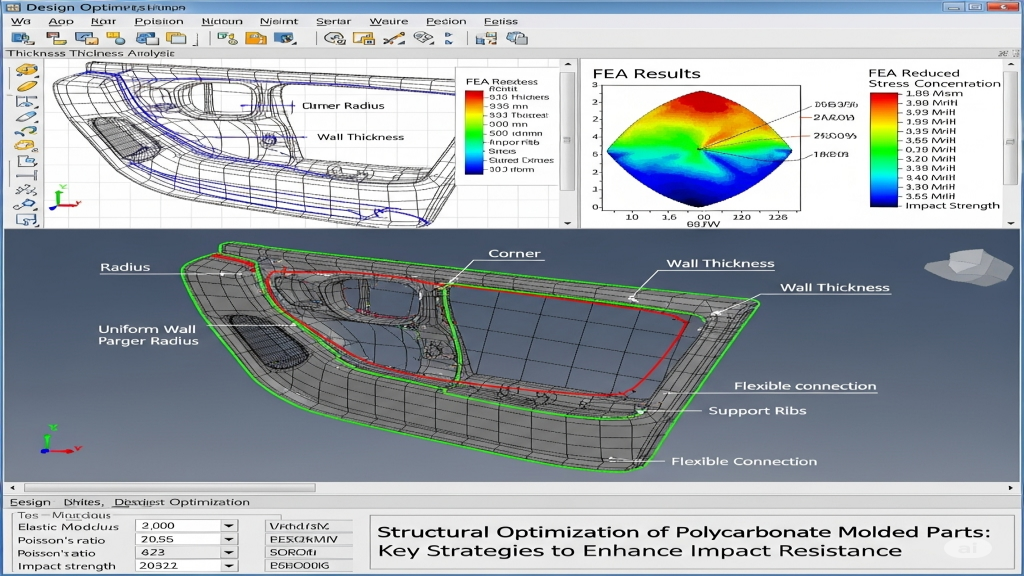

How to optimize the structure for better impact resistance?

Reasonable structural design of polycarbonate injection parts can effectively reduce stress concentration. Reinforced ribs, radiused corners, and consistent wall thickness are typical strategies. Local structure optimization significantly enhances overall impact resistance.

- Increase corner radius: Reduce stress concentration from sharp angles.

- Optimize wall thickness: Uniform walls reduce deformation risk.

- Add support ribs: Improve impact resistance through reinforcement.

- Avoid abrupt connections: Flexible joints reduce impact transmission.

How can processing control reduce the effect of impact load?

PC has a narrow molding window. Slight parameter fluctuations during processing may lead to internal stress and cracking. Control over molding temperature, injection speed, and cooling time is crucial. Accurate parameter control ensures impact performance.

- Optimize injection speed: Moderate speed balances flow and orientation.

- Control mold temperature: Stable mold temp reduces internal stress.

- Extend holding time: Ensure density and part integrity.

- Choose proper cooling method: Improve crystallinity and mechanical strength.

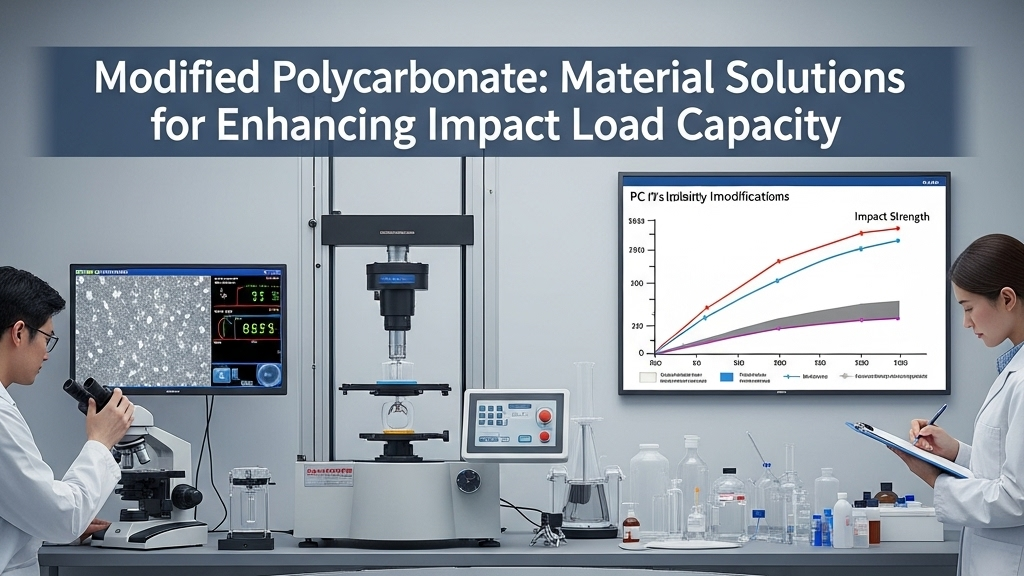

Can modified materials enhance impact load tolerance?

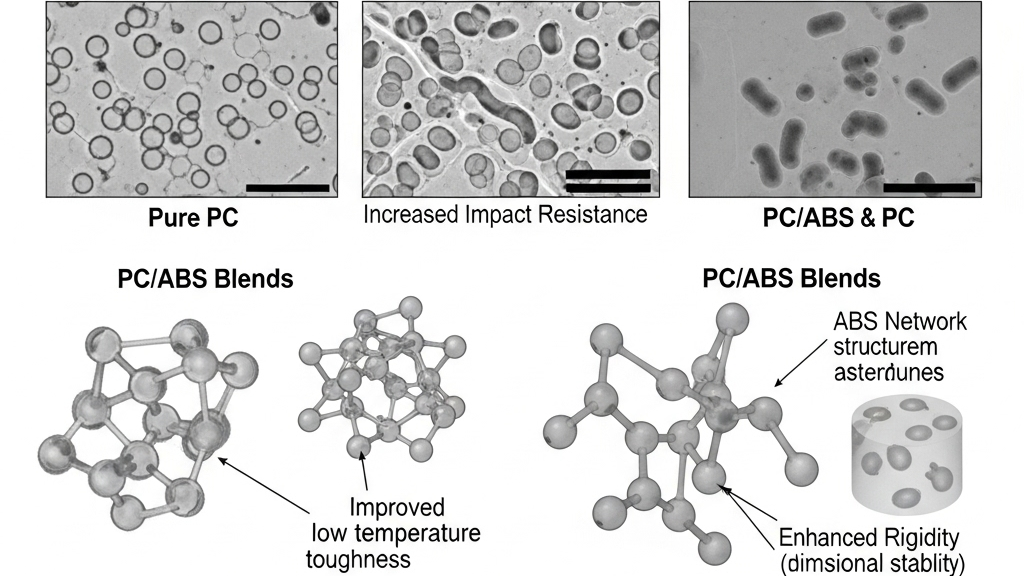

Adding elastomers or modifiers into PC improves impact resistance and processing stability. Glass fiber reinforcement and blending techniques are also commonly used. Proper material selection balances performance and cost.

- ABS blends: Improve low-temperature toughness.

- Elastomer modification: Enhance ductility and reduce brittleness.

- Glass fiber reinforcement: Improve rigidity and dimensional stability.

- Add anti-stress cracking agents: Extend service life.

Comparison of PC Injection Impact Designs

|

Item |

Standard PC Part |

Modified PC (ABS) |

Rib-Reinforced PC |

Elastomer-Blend PC |

| Impact Resistance | Medium | High | High | Very High |

| Processing Difficulty | Low | Medium | Medium | High |

| Cost Efficiency | Excellent | Moderate | Moderate | High |

| Cycle Time | Fast | Medium | Medium | Slow |

| Stress Risk | High | Medium | Low | Low |

| Transparency | High | Medium | Medium | Medium |

| Equipment Need | Standard | Standard | Standard | High |

| Recommended Use | Basic housings | Engineering parts | Protective shells | Drop-resistant parts |

Application potential

As a high-performance injection material, PC has wide potential for impact-related applications. With advancing modification tech and simulation tools, its possibilities are expanding. PC parts will face higher performance demands in EVs, 5G and smart devices.

1.Structure: Multi-cavity design reduces stress points.

2.Application: From industry to medical and consumer.

3.Technology: Simulate impact analysis in design phase.

4.Product: Add functional fillers or nanomaterials.

Conclusion

To handle impact loads, PC injection parts must be optimized in structure, processing, and materials. Managing stress sources and structure details improves impact durability. Companies should focus on long-term performance and application flexibility to gain market edge.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: May-23-2025