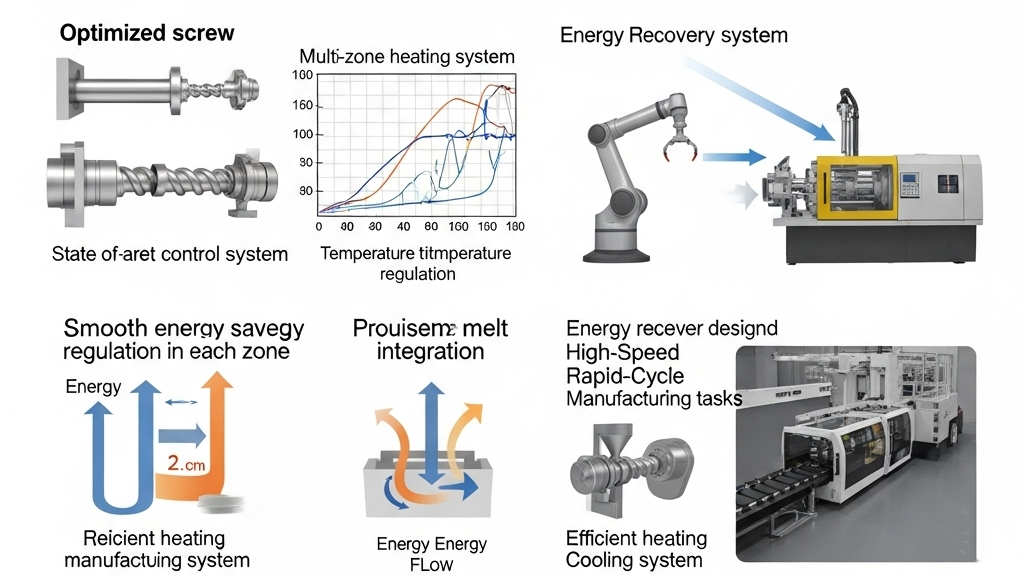

The screw structure of an injection molding machine directly determines plasticizing efficiency and product quality, making it a core component of the molding system. A well-designed screw shortens cycle times while reducing energy consumption and material waste.Efficient screw design is the fundamental base for improving molding performance.

In industrial applications, more companies are turning to custom screw designs tailored to material types and product geometry. By optimizing geometry and heating zone layout, melt quality can be improved and defect rates minimized.Custom screw structures help ensure stable output under varying processing conditions.

How Can Structural Design Improve Screw Plasticizing Efficiency?

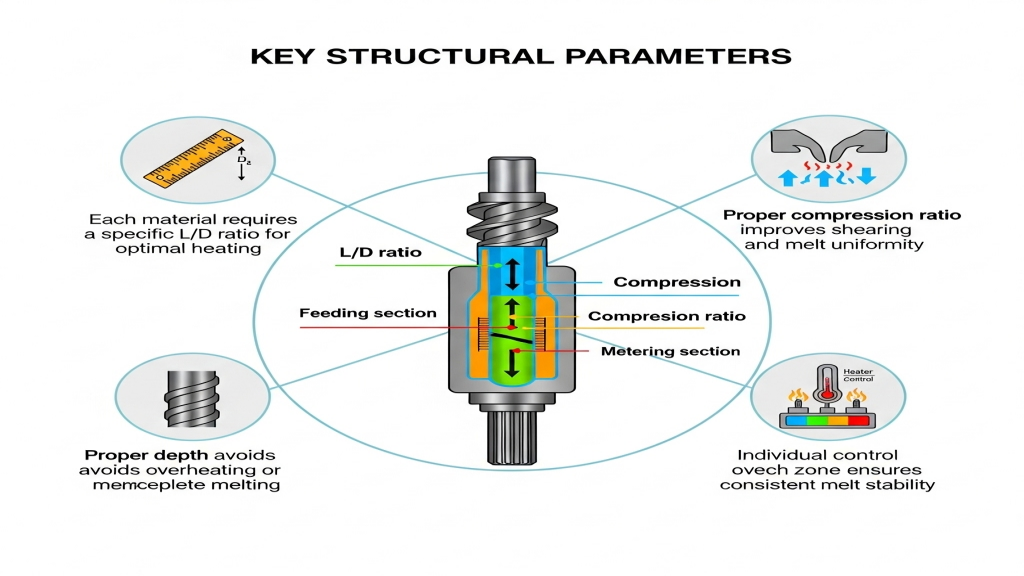

Optimizing L/D ratio, compression ratio, and thread depth in each zone enhances material feed and melting quality. Good melting efficiency is a prerequisite for molding stability. Choosing the right screw type for different materials is also crucial.

- Compression Ratio Selection: Proper compression ratio improves shearing and melt uniformity.

- L/D Ratio Adjustment: Each material requires a specific L/D ratio for optimal heating.

- Thread Depth Optimization: Proper depth avoids overheating or incomplete melting.

- Segmented Heating Control: Individual control over each zone ensures consistent melt stability.

How to Evaluate Screw Compatibility with Different Materials?

Materials vary greatly in heat sensitivity, shear response, and viscosity behavior. Material-specific screw design helps prevent over-shearing and material degradation. Customizing screw zone geometry for each plastic type improves melt consistency.

- Heat-Sensitive Material Matching: Lower shear zones are suitable for PVC, POM, etc.

- High-Flow Materials Adaptation: PP, PE need optimized feed zone taper for consistency.

- Filled Materials Consideration: Glass-fiber or mineral-filled plastics need reinforced mixing zones.

- High-Viscosity Design: Materials like PC and PMMA require strong shear mixing zones.

How Does Screw Design Affect Product Appearance and Performance?

Screw design affects surface uniformity, internal density, and mechanical strength of molded parts. Shear uniformity of the screw plays a decisive role in transparency and surface gloss. Mold filling consistency also depends on melt homogeneity.

- Optical Clarity Design: For transparent PC, PMMA, mixing zone must reduce air entrapment.

- Thin-Walled Part Forming: Screw must respond quickly to ensure proper melt at short cycles.

- Mechanical Strength Balance: Consistent melt minimizes residual stress and boosts durability.

- Color Consistency: Uniform melt helps avoid color streaks and ensures appearance quality.

Screw Type vs. Material Matching Table

|

Screw Type |

Suitable Materials |

Compression |

L/D Ratio |

Typical Use |

Strengths |

Weaknesses |

Heating Zones |

| General Purpose | ABS/PP/PE | 2.2:1 | 20:1 | Appliance Housings | Low cost, high versatility | Color variation | 3 zones |

| Barrier Screw | PA+GF/PC | 3.0:1 | 24:1 | Structural Parts | Enhanced shear/mixing | Wear sensitivity | 4 zones |

| Separation Screw | PVC/POM | 1.6:1 | 18:1 | Pipes, Components | Low degradation risk | Slower melt | 3 zones |

| Mixing Screw | PMMA/PC+GF | 2.8:1 | 22:1 | Light Covers | Uniform melt, better optics | Higher cost | 4 zones |

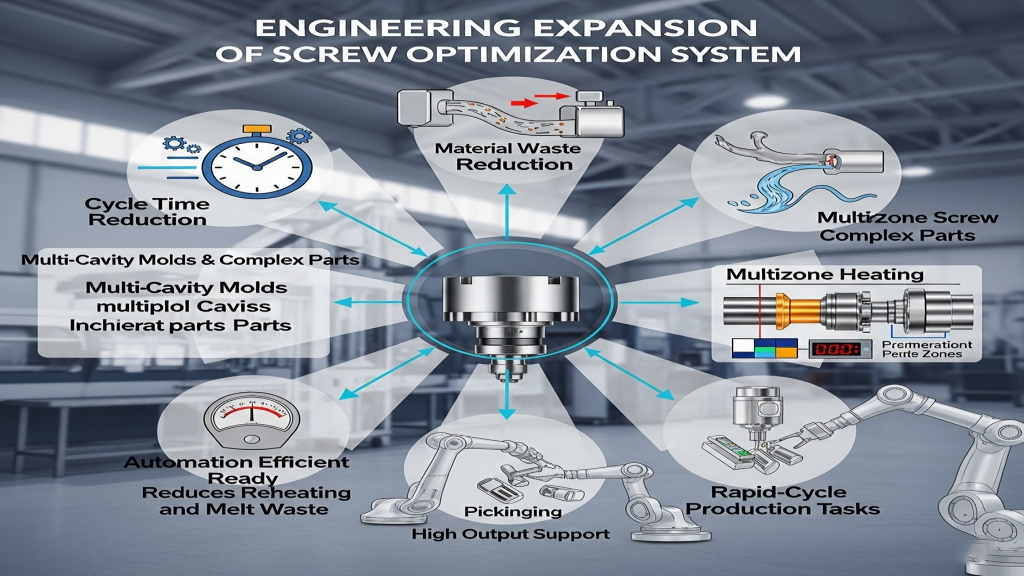

Engineering Expansion of Screw Optimization

Optimizing screws goes beyond plasticizing—it extends to cycle time, energy use, and automation compatibility. A well-engineered screw system significantly reduces molding cycle and material waste. For multi-cavity molds and complex parts, high-response screw structures are essential.

1.Precision Control: Multizone heating ensures melt stability.

2.Automation Ready: Easily integrates with robotic systems.

3.Energy Efficient: Reduces reheating and melt waste.

4.High Output Support: Suitable for rapid-cycle production tasks.

Conclusion

Optimizing screw structure is not only essential for plasticizing efficiency, but also the basis for achieving consistent product quality. When facing diverse materials and complex geometries, manufacturers must pay close attention to screw system matching and refinement. With scientific selection, thoughtful design, and closed-loop feedback, overall production efficiency can be significantly improved.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-09-2025