Introduction

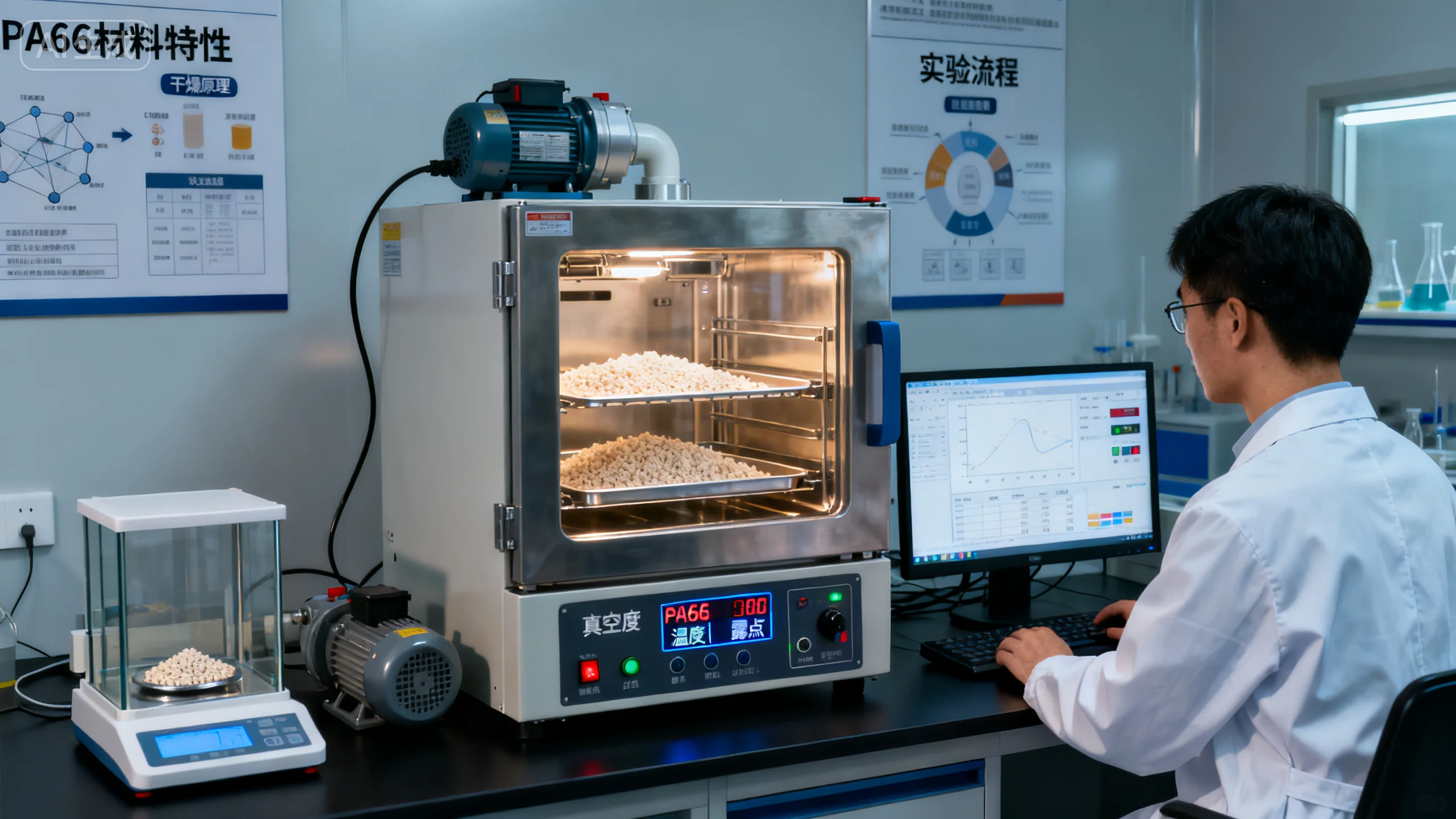

Moisture-sensitive materials are highly prone to defects such as bubbles, splay marks, or dull surfaces during injection molding, caused by humidity variations. Controlling material moisture content is the key to ensuring product stability and surface quality. Neglecting proper drying or storage often results in higher scrap rates during mass production.

In high-performance polymers like PA, PC, and PET, moisture absorption is particularly critical. A systematic drying and environmental control plan helps prevent hydrolysis and property loss. A well-designed pretreatment process significantly enhances mold life and product consistency.

Why do moisture-sensitive materials easily produce defects during molding?

Moisture absorbed by the material vaporizes during high-temperature melting, creating voids, silver streaks, and surface unevenness. The presence of moisture breaks polymer chains, reducing mechanical strength and transparency. Without proper control, these issues magnify in continuous production.

- Drying Temperature Control: Accurate drying temperature prevents thermal degradation.

- Vacuum Dehumidification: Speeds up moisture removal in low-pressure environments.

- Dew Point Monitoring: Tracks air quality to ensure consistent dryness.

- Hopper Insulation Design: Reduces moisture reabsorption risk.

Accurate drying management effectively prevents defect formation.

How can reabsorption of moisture be prevented during production?

Production humidity, exposure time, and storage conditions determine the risk of reabsorption. Even well-dried materials can quickly regain moisture in a humid environment. Therefore, closed storage and quick transfer are essential for maintaining dryness.

- Sealed Storage System: Use airtight bins with dry-air circulation.

- Quick Feeding System: Shortens exposure and preserves dryness.

- Climate-Controlled Workshop: Keeps relative humidity below 40%.

- Moisture-Proof Packaging: Use aluminum or multilayer film bags.

Post-drying protection is the second defense against quality loss.

How can mold design minimize the impact of moisture defects?

Mold structure and venting systems are crucial when processing moisture-sensitive materials. Proper temperature control and venting greatly reduce trapped gas and surface flaws. Optimizing gate location and runner size also improves filling uniformity.

- Mold Venting Design: Improves air escape and reduces gas trapping.

- Runner Smoothness Optimization: Minimizes melt retention and bubbles.

- Localized Temperature Control: Ensures balanced cooling zones.

- Vacuum-Assisted Mold: Enhances density and surface clarity.

A well-engineered mold design tackles moisture defects at the source.

Comparison Table of Drying Methods for Hygroscopic Materials

|

Material Type |

Drying Temp (℃) |

Drying Time (h) |

Recommended Equipment |

Post-Drying Time Limit |

| PA6 | 80–90 | 4–6 | Hot Air Dryer | Use within 6 hrs |

| PC | 110–120 | 3–4 | Dehumidifying Dryer | Use within 8 hrs |

| PET | 160–170 | 4–5 | Vacuum Dryer | Use within 4 hrs |

| TPU | 90–100 | 2–3 | Hot Air/Rotary Dryer | Use within 5 hrs |

Drying is just the beginning — want to eliminate moisture-related defects for good? contact us today for a customized solution!

Environmental Optimization Strategies

The production environment is a hidden yet critical factor for molding stability. High humidity and poor air circulation can cause reabsorption during material transfer. Continuous humidity control and automated dehumidification systems are vital for consistent quality. With digital environmental monitoring, manufacturers can reduce human error and achieve process stability.

1.Humidity Monitoring: Use automatic dew point sensors.

2.Airflow Management: Improve ventilation to prevent condensation.

3.Dedicated Drying Zones: Isolate humid air sources.

4.Online Data Logging: Build a trackable environmental record.

Conclusion

Controlling moisture-sensitive materials in injection molding requires a holistic approach covering materials, equipment, molds, and environment. A balanced combination of precise drying, sealed storage, and optimized mold design can eliminate most moisture-related defects. Continuous environmental improvement will further enhance product consistency and competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-17-2025