Polycarbonate (PC) is widely used in impact-resistant outdoor and industrial applications due to its excellent properties. In low-temperature environments, reduced molecular mobility significantly increases the risk of brittle fracture, posing potential hazards. Through formula optimization and precise processing, the service window of PC parts can be extended effectively.

With the rise of cold chain logistics, polar equipment, and frigid zone infrastructure, PC injection parts are facing severe impact and drop challenges. Companies that can systematically address low-temperature brittleness will stand out in high-value markets. Material modification and strict quality control are key to gaining customer trust.

Why does polycarbonate tend to crack in low temperatures?

Low temperatures reduce PC’s ability to absorb impact below its alpha-transition temperature, causing microcracks to rapidly propagate under residual stress. Rapid cooling or inadequate stress relief during processing exacerbates the risk of brittle failure. Cold-resistant additives, mold temperature control, and post-treatment help lower fracture rates.

- Material Modification: Rubber modifiers improve fracture elongation at low temperatures.

- Mold Temperature Control: Balanced thermal fields reduce internal stress.

- Stress Relief: Annealing eliminates residual stress and prevents microcracks.

- Batch Monitoring: Cold-drop testing screens out defective parts.

How to prevent cracking during production?

Proper screw shear and injection speed balance melt viscosity and avoid over-stretching of polymer chains. Optimized venting and runner designs reduce weak weld lines that cause cracks. Real-time monitoring of melt and mold temperature curves ensures consistent processing.

- Online Monitoring: Sensor data adjusts injection parameters in real-time.

- Shear Control: Prevents molecular degradation and retains toughness.

- Venting Optimization: Removes trapped air to prevent silver streaks and cracks.

- Melt Homogenization: Static mixers improve uniformity.

How to verify low-temperature reliability after delivery?

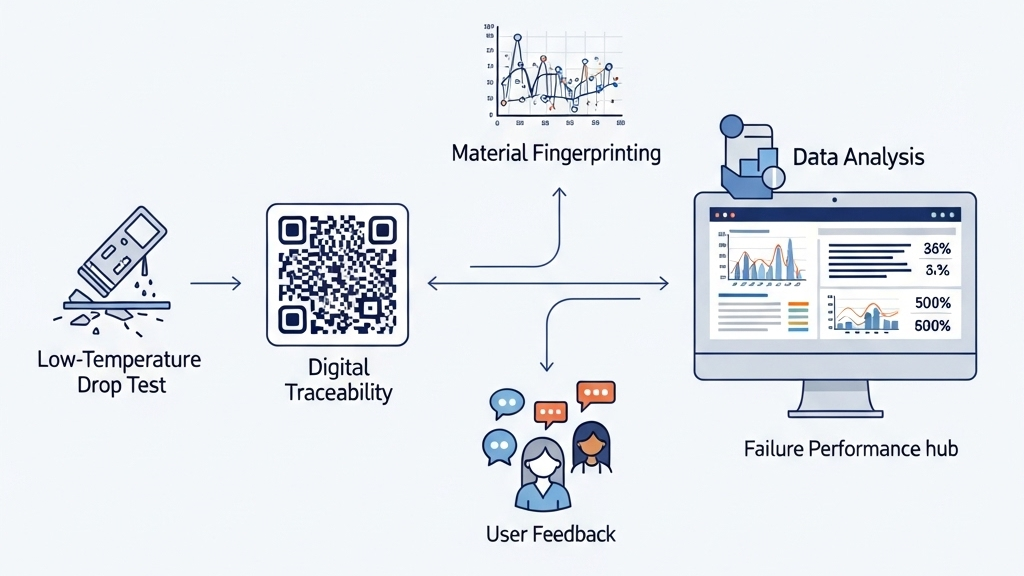

Post-delivery testing simulates real use by repeatedly impacting parts in cold conditions and tracking failure rates. Material fingerprinting helps trace failures back to specific batches. End-user feedback also enables ongoing improvements to formulation and processing.

- Drop Testing: Standardized tests to assess low-temp impact performance.

- Digital Traceability: QR codes link batch data and performance.

- On-Site Reviews: Gather real-world usage data.

- Data Analysis: Guides formulation improvements.

Low-Temperature Anti-Brittle Solutions Comparison

|

Item |

Modified PC |

Cold-Resistant PC |

Glass-Filled PC |

Blended PC |

| Impact Temp | -40 °C | -50 °C | -30 °C | -45 °C |

| Charpy Value | 18 kJ/m² | 22 kJ/m² | 25 kJ/m² | 20 kJ/m² |

| Flowability | Medium | Medium-High | Low | Medium |

| Cost | Medium | High | Medium | Low |

Expansion

In extreme climate applications, systematic coordination between materials and processes is the key to unlocking high-end markets. By offering technical output and customized services, companies can build competitive barriers. Reliability testing and post-sale solutions around low-temp toughness will increase brand loyalty and broaden adoption.

1.Market Opportunity: Cold-region infrastructure drives demand for tough PC.

2.Tech Licensing: Transfer formulas and processing standards to partners.

3.Service Value-Add: Provide rapid low-temperature impact testing.

4.Brand Advantage: Strengthen trust via traceability systems.

Conclusion

Low-temperature brittleness is not the “fate” of PC injection parts—it can be overcome through a triad of material, processing, and testing strategies. Those who lead in low-temp reliability will dominate pricing in cold-climate markets. Moving forward, high-toughness PC will become the preferred material for cold-chain and polar equipment. Ongoing innovation and service improvements will drive sustained success.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-13-2025