Introduction

In injection molding, static buildup can cause surface dust attraction, discharge damage, and reduced product performance. By introducing electrostatic dissipative (ESD) technologies, manufacturers can enhance both safety and functional stability. ESD modification not only improves surface cleanliness but also strengthens the protection of electronic components.

As industries demand more functional materials, manufacturers are turning to modified plastics to counteract static-related risks. Whether in automotive interiors, medical devices, or electronic housings, static control has become a key element of quality optimization. Mastering ESD modification technology is the key to achieving performance breakthroughs in high-end injection molded parts.

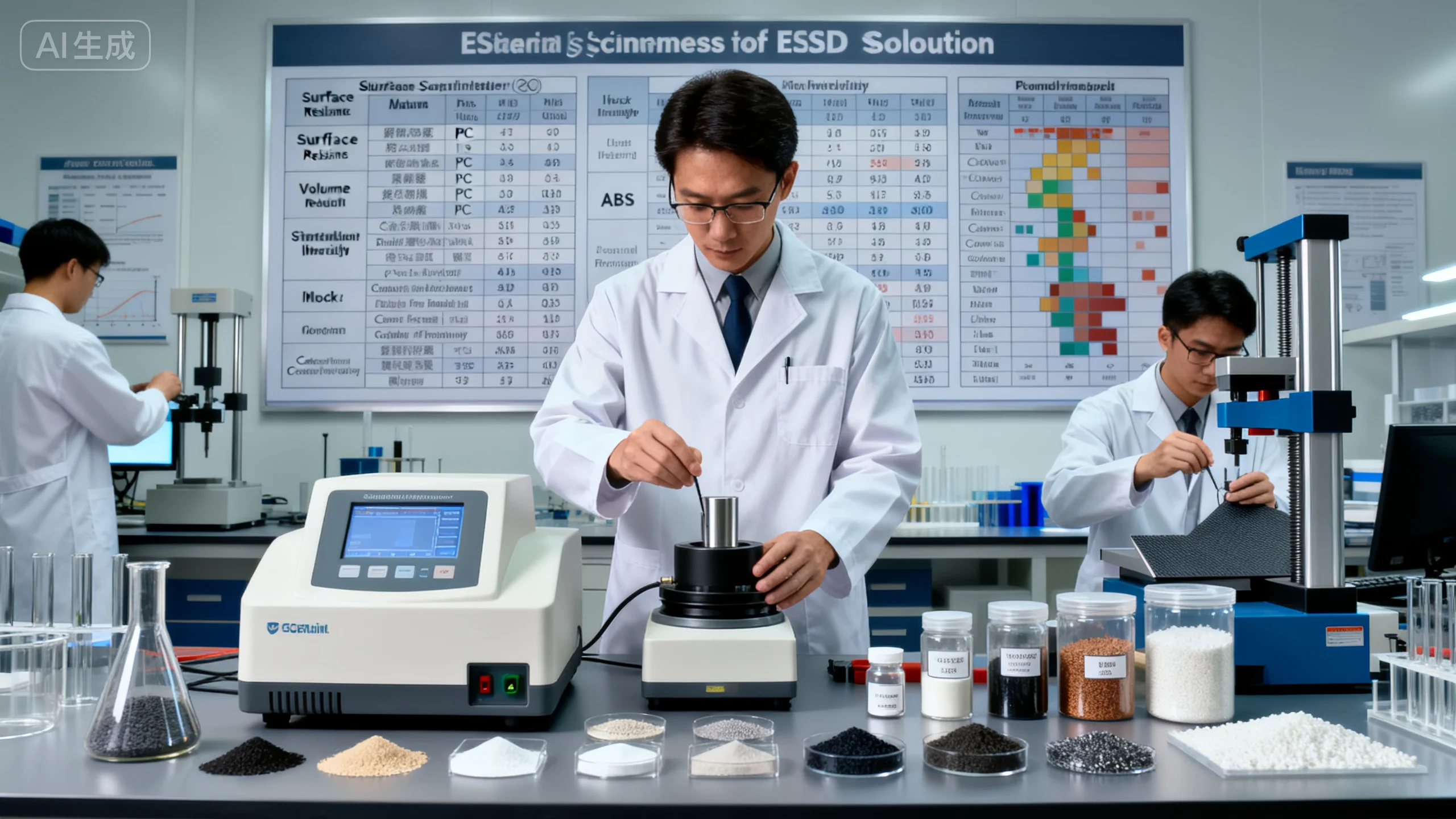

How Can Electrostatic Dissipative Modification Be Achieved in Injection Molding?

ESD modification is realized by incorporating conductive fillers, antistatic agents, or carbon nanomaterials into the plastic matrix. This technology effectively prevents static accumulation and extends product lifespan. Selecting proper material systems and processing methods ensures stable and consistent dissipation performance.

- Conductive Filler Application (Learn more): Adding carbon black, graphene, or carbon nanotubes to create conductive networks.

- Antistatic Agent Modification: Using permanent or migratory antistatic agents to improve surface conductivity.

- Carbon-Based Reinforcement (Technical Paper): Balancing dissipation performance with mechanical properties using carbon-based nanocomposites.

- Blending Process Optimization: Controlling mixing uniformity to prevent filler agglomeration.

ESD modification is an efficient approach combining functionality and safety.

How to Choose the Right Dissipative Material System?

Material selection depends on environmental conditions, resistance requirements, and processing compatibility. Finding the right balance between performance and cost is the foundation of any ESD solution. By selecting optimal filler ratios and base polymers, manufacturers can achieve stable dissipation effects while maintaining mechanical strength.

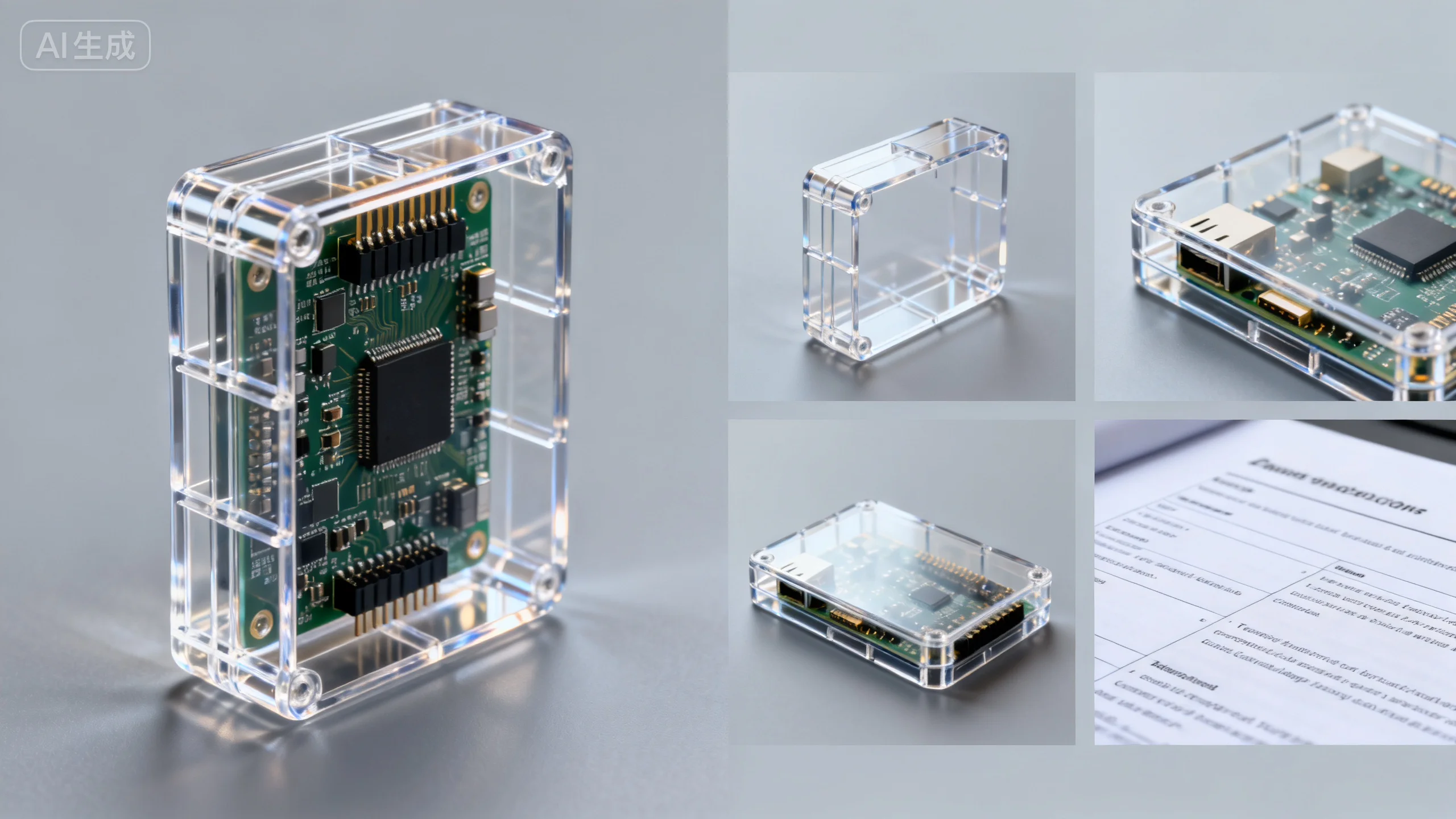

- Polycarbonate-Based Systems (Reference Case): Ideal for electronic housings with high transparency and impact resistance.

- Conductive ABS: Commonly used for automotive dashboards and home appliances, balancing processability and dissipation.

- Polyolefin Blends (Technical Insight): Excellent cost efficiency for packaging and medical applications.

- Carbon Fiber Reinforcement: Enhances conductivity and mechanical strength in high-performance structural parts.

Scientific material selection is the starting point for balanced performance.

What Are the Effects of ESD Modification on Injection Performance?

ESD modification influences not only conductivity but also flowability, mechanical strength, and appearance. The compatibility between material design and molding process determines the final product quality. In production, both dissipation efficiency and molding stability must be optimized together.

- Flow Behavior Changes (Technical Reference): Conductive fillers increase melt viscosity, requiring parameter adjustments.

- Mechanical Property Balance: Carbon fillers raise modulus but may reduce ductility.

- Surface Finish Control: Filler dispersion affects gloss and coating adhesion.

- Durability & Aging: Migratory agents may lose performance over time.

Balancing dissipation and molding quality begins at the design stage.

Comparison Table of Common Dissipative Materials

|

Material Type |

Surface Resistance (Ω) |

Cost Level |

Weatherability |

Transparency |

Processability |

Typical Application |

Recyclable |

| Carbon Black PC | 10⁶ | Medium | High | Low | Good | Industrial Housings | Yes |

| Graphene PP | 10⁵ | High | Excellent | Medium | Fair | Electronic Casings | No |

| Antistatic ABS | 10⁸ | Low | Medium | High | Excellent | Automotive Interiors | Yes |

| CNT-Modified PA | 10⁴ | High | Excellent | Medium | Medium | Medical Components | No |

Want to know which solution best fits your needs? Click contact us for technical consultation.

The Future of Functional ESD Integration

With the progress of intelligent manufacturing, ESD materials are increasingly merging with EMI shielding and thermal management functions. Advanced composite systems will become the key to competitive product performance. By integrating conductive and structural properties, manufacturers can achieve lightweight and multifunctional designs.

1.Nanomaterial Applications: Enhancing both dissipation and mechanical strength.

2.Smart Conductive Polymers: Enabling self-sensing and environmental response.

3.Eco-Friendly Formulations: Reducing the use of permanent additives for sustainability.

4.Functional Injection Integration: Combining multi-cavity molds for dual-purpose designs.

Conclusion

Electrostatic dissipative modification makes injection molded parts safer, more reliable, and more versatile. Through scientific material design and precise molding control, it is possible to achieve a perfect balance between functionality and appearance. Looking ahead, ESD modification is evolving toward intelligent and sustainable solutions, unlocking new potential for the plastics industry.

For expert assistance in implementing electrostatic dissipative modification for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-13-2025