Polypropylene (PP) is widely used in injection molding for automotive, household, and consumer goods due to its excellent chemical resistance and processability. In long-term outdoor or high-temperature environments, PP products are prone to surface discoloration. The visual quality of plastics directly affects brand perception and market competitiveness.

To counter discoloration, companies must focus on raw material ratios, additive choices, and mold design in production. A correct technical approach effectively extends product lifespan and maintains surface aesthetics.

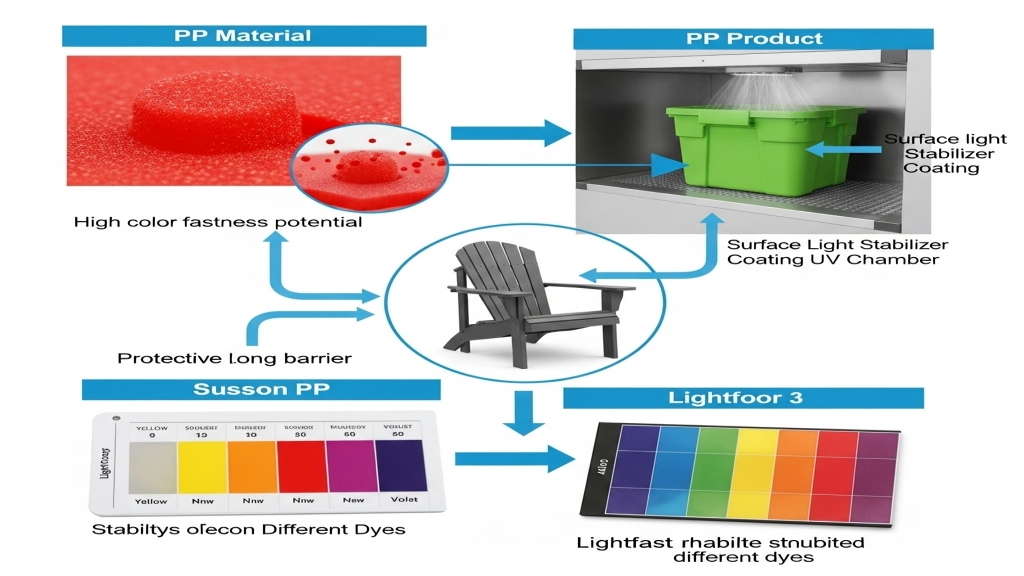

Is Color Fastness the Core Factor?

In PP injection molding, poor dispersion of color masterbatch and insufficient lightfastness of dyes are key causes of fading. Color fastness is not only a visual standard but also reflects product reliability and customer satisfaction.

- High-dispersion Masterbatch: Ensures color consistency and stability.

- Surface Light Stabilizer Coating: Enhances UV resistance after molding.

- Lightfast Dye Systems: Better UV-resistant dyes reduce fading.

- Raw Material Consistency Control: Prevents batch-to-batch color variation.

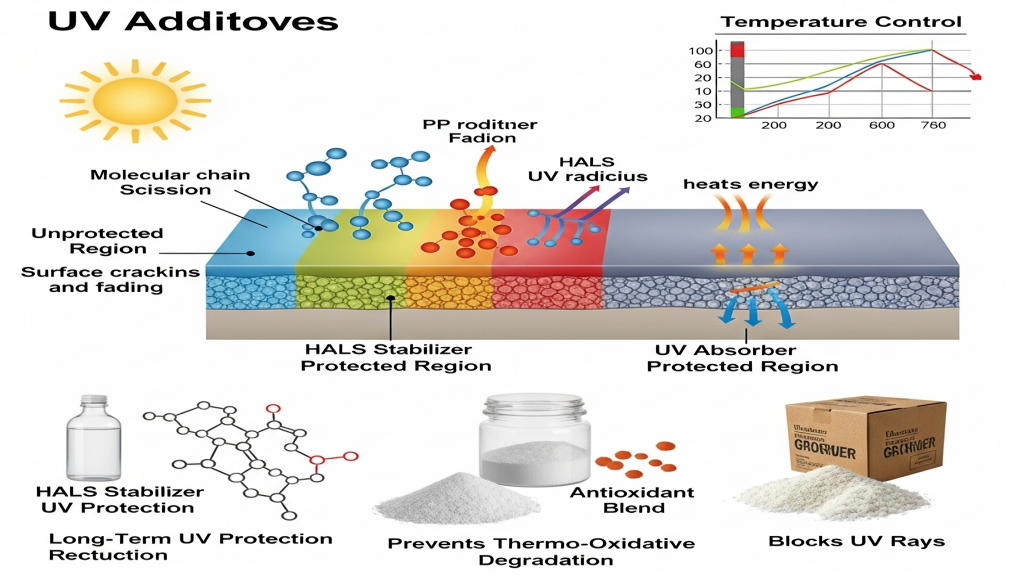

How to Choose UV Additives?

UV degradation significantly impacts color retention of PP products, especially in outdoor use. Proper UV additive selection is key to improving weather resistance.

- HALS Stabilizers: Provide long-term UV protection.

- Antioxidant Blends: Prevent discoloration caused by thermo-oxidative degradation.

- UV Absorbers: Block UV rays and protect colorants.

- Accurate Process Temperature Control: Prevents additive breakdown from overheating.

Does Injection Molding Process Affect Discoloration?

Temperature, time, and shear rate in injection molding affect the bonding between pigments and the PP matrix. Proper process control is fundamental to maintaining product color stability.

- Precise Temperature Control: Ensures uniform melt consistency.

- Accurate Masterbatch Dosing: Prevents color deviation.

- Optimized Screw Design: Enhances mixing and pigment dispersion.

- Effective Mold Venting: Reduces defects like burn marks and bubbles.

Weather Resistance Comparison Table

|

Material Type |

UV Resistance |

Cost Control |

Color Deviation |

Application Fit |

| Regular PP | Low | Excellent | Unstable | Indoor short-term |

| UV-Modified PP | High | Moderate | Stable | Long-term outdoor |

| Masterbatch-Filled PP | Moderate | Moderate | Good | General industrial |

| Weather-Grade Alloy PP | Very High | High | Very Stable | Premium appliance |

Material application

PP is no longer limited to traditional household products; its usage has expanded into automotive interiors, outdoor projects, and medical packaging. As functionality demands grow, so do requirements for weather resistance and color retention.

1.Automotive Components: Must resist heat and sunlight with color consistency.

2.Outdoor Furniture: UV protection and colorfastness are key.

3.Medical Packaging: Requires tight control over color uniformity.

4.Construction Pipes: Needs stress resistance and color durability.

Conclusion

Discoloration in PP injection products is preventable with proper design, process control, and material selection. UV systems, dye choices, and temperature regulation are the three pillars of stable product performance.

In commercial practice, companies should define product application scenarios early in R&D to determine optimal additive and process combinations. Through technical advancement and precise management, greater market success can be achieved.

For expert assistance in implementing solutions for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: May-26-2025