Introduction

In today’s precision manufacturing landscape, micro molds represent not just miniaturization but the convergence of technology, accuracy, and reliability. EEAT (Experience, Expertise, Authoritativeness, Trustworthiness) has become a key standard to evaluate manufacturing credibility and process transparency. By implementing high-precision micro molding, manufacturers can deliver consistent, trustworthy performance across every component.

In our one-stop injection molding solutions, micro molds achieve EEAT compliance through rigorous process control, digital design, and validation testing. This is not only a demonstration of technical capability but also a cornerstone of brand credibility and customer confidence.

How Do Micro Molds Achieve EEAT Assurance During Manufacturing?

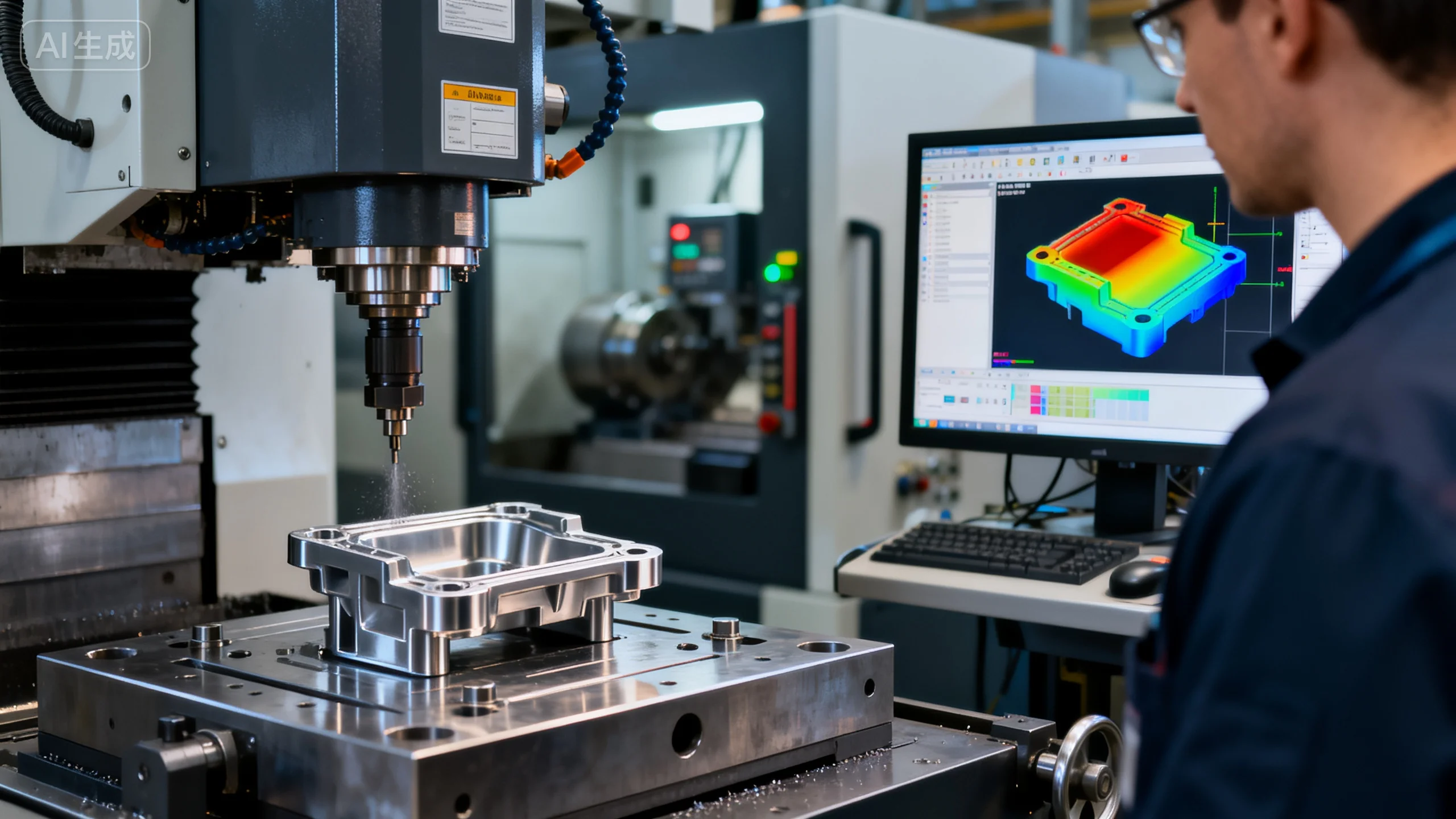

EEAT assurance in the manufacturing stage is achieved through digitalized production, dimensional precision, and process traceability. Using advanced CNC and EDM systems, manufacturers can maintain dimensional errors within microns. This standardized workflow ensures full data transparency and technical verification, forming a foundation of customer trust.

- Precision Manufacturing Control: High-precision CNC and EDM machining guarantee dimensional uniformity.

- Material Traceability System: Each material batch is traceable, ensuring performance stability.

- Smart Inspection Technology: 3D and microscopic inspection enhance mold accuracy.

- Production Data Logging: MES systems capture process data for complete traceability.

The core of EEAT in micro mold manufacturing lies in “precision, transparency, and verification.”

How Do Micro Mold Designs Demonstrate Expertise and Authority?

EEAT in the design stage is realized through expert engineering teams and CAE simulation tools. The complexity of micro molds demands deep technical knowledge and material insight. Through digital simulations, we predict flow channels, venting, and thermal behavior to ensure every design achieves functional and aesthetic precision.

- CAE Simulation Validation: Predicts molding flow and deformation to eliminate design flaws.

- Modular Design Philosophy: Enhances maintenance and interchangeability efficiency.

- Expert Review Team: Senior engineers with over 10 years of experience review each project.

- Client Co-Creation Model: Incorporates customer feedback for functional accuracy.

Establishing expertise and authority begins at the design stage — the foundation of EEAT assurance.

How Do Micro Molds Maintain Trust and Consistency During Mass Production?

EEAT during mass production focuses on process stability and product consistency. By maintaining strict control of injection parameters and preventive mold maintenance, variations between batches are minimized. Automated monitoring systems further ensure all production deviations remain within control limits, reinforcing long-term reliability and customer trust.

- Automated Monitoring System: Enables closed-loop control of temperature, pressure, and cycle time.

- Standardized Maintenance Plan: Preventive upkeep ensures mold lifespan stability.

- Regular Sampling Inspection: Verifies surface and dimensional consistency.

- Data-Driven Optimization: AI-based analysis enhances production stability.

Consistent quality in mass production is the strongest proof of EEAT trustworthiness.

EEAT Performance Comparison of Micro Mold Stages

|

Comparison Item |

Design EEAT |

Manufacturing EEAT |

Mass Production EEAT |

Customer Experience EEAT |

| Expertise Level | High | Mid-High | High | High |

| Process Transparency | Medium | High | High | High |

| Traceability | Medium | High | High | High |

| Customer Trust Index | Medium | Mid-High | High | Very High |

In the EEAT system of micro molding, every stage of optimization directly strengthens client trust and brand value. Want to learn more? contact us.

Expansion

EEAT in micro molds extends beyond manufacturing — it includes material innovation, data synergy, and customer engagement. By leveraging digital twin technology, we enable full-cycle visualization from design to delivery. This transparency empowers customers to monitor production progress and verify quality in real-time.

1.Digital Collaboration: Real-time data sharing across departments.

2.Customer Visualization Interface: Real-time project tracking dashboard.

3.AI Material Selection: Automatically recommends optimal resins for applications.

4.Sustainable Manufacturing Strategy: Green energy and recycling reduce carbon footprint.

Conclusion

EEAT compliance in micro molding represents the fusion of technology, process control, and trust. Through precision engineering, expert design, and transparent management, manufacturers build long-term credibility and customer confidence. In a competitive manufacturing world, EEAT is not just a framework — it’s a brand differentiator.

For expert assistance in implementing EEAT-ready micro molding for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-10-2025