Introduction

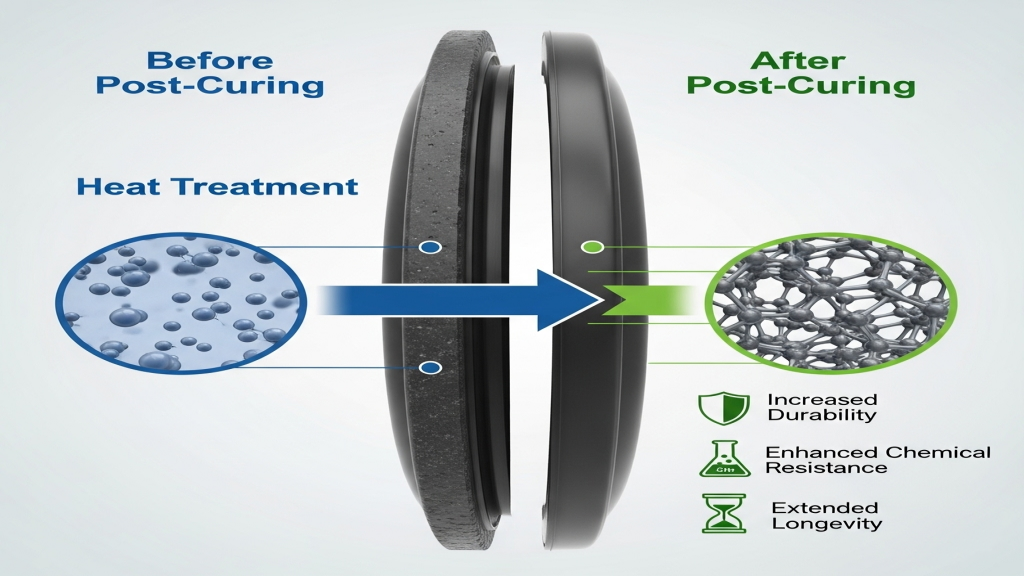

The performance of rubber parts can still be enhanced after initial processing. Post-curing is a key step that thermally treats already-vulcanized rubber, refining its molecular structure, improving density, and enhancing mechanical strength and aging resistance.Post-curing significantly increases the wear resistance and service life of rubber lips.

In lip seal applications, maintaining both abrasion resistance and elasticity is essential. A proper post-curing process not only improves the shape recovery of the lip but also boosts its media resistance, minimizing early-stage wear.Refined structure and hardness distribution at the lip are direct benefits of post-curing.

How does post-curing improve the wear resistance of rubber lips in metal contact?

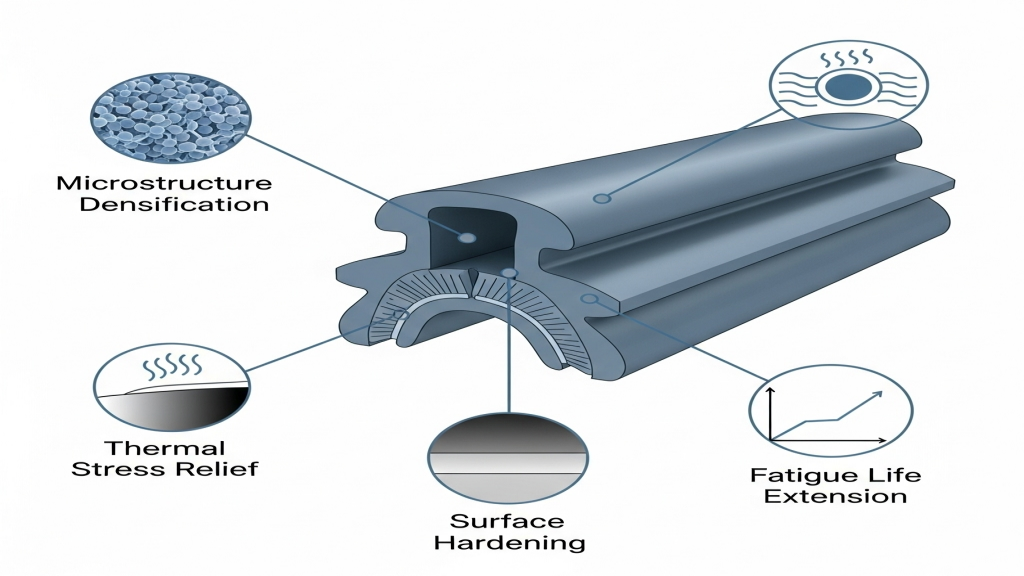

When in contact with metal shafts, lips endure both friction and pressure, leading to localized heat and fatigue damage. Post-curing rearranges rubber chain segments and strengthens cross-linking density, enhancing thermal tolerance.This treatment effectively reduces particle detachment and structural weakening during operation.

- Microstructure Densification: Polymer crosslinking enhancement increases abrasion resistance

- Thermal Stress Relief: Releases residual stress from primary vulcanization, improving dimensional stability

- Surface Hardening Effect: Post-vulcanization equalization improves surface hardness gradient

- Fatigue Life Extension: Enhances sealing performance under continuous operation

Post-curing optimizes structure to greatly improve rubber lip wear resistance against metal surfaces.

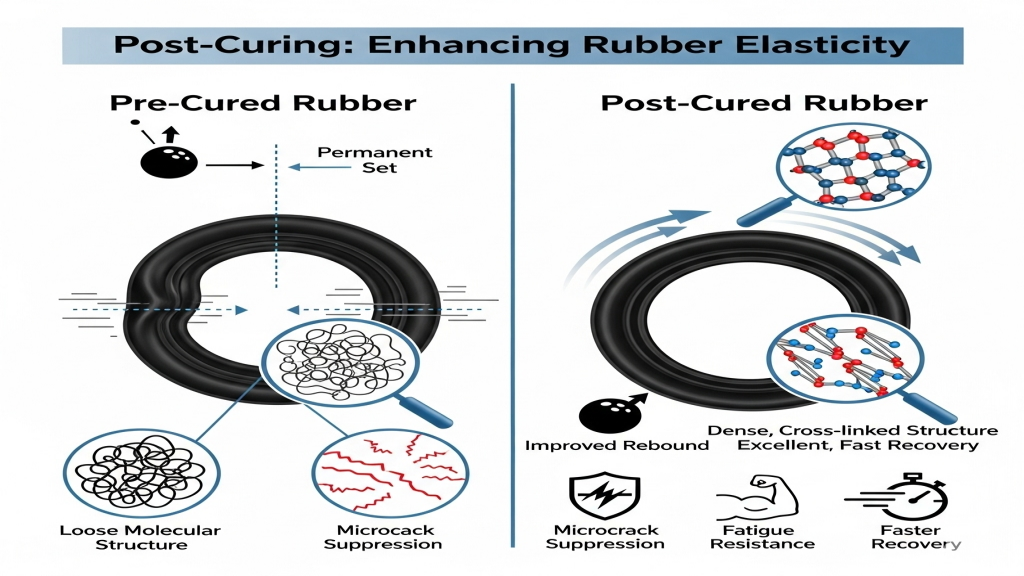

Why does post-curing enhance elasticity and recovery in rubber?

Rubber components frequently undergo compressive deformation and dynamic loading, especially in lip regions. Post-curing balances cross-linking between segments, supporting repeated energy release and reducing permanent deformation.This reinforcement enables lips to better adapt to high-speed or reciprocating motion.

- Improved Rebound Performance: Elastic recovery treatment reduces permanent set

- Microcrack Suppression: Denser structure inhibits initial crack formation

- Enhanced Compression Fatigue Resistance: Withstands cyclic compressive loads better

- Faster Deformation Recovery: Optimizes hysteresis, improving response time

Post-curing boosts rubber recovery ability after deformation, crucial for sealing reliability.

How does post-curing optimize rubber lip formulations and stability?

Post-curing is more than a physical process—it also promotes uniform redistribution of additives in rubber compounds. For seals containing carbon black, sulfur agents, and antioxidants, post-curing enhances synergistic reactions and material stability.Formulation stability and anti-aging performance are fundamental to consistent lip behavior.

- Additive Redistribution: Migration control technology improves aging resistance

- Molecular Chain Stabilization: Reduces volatility-induced instability

- Hardness Gradient Control: Balances surface-core property distribution

- Process Adaptability Enhancement: Improves compatibility with overmolding or plastic-injection procedures

Improved compound stability makes lips more durable under high-temperature and high-pressure conditions.

Post-curing Methods and Their Effects

|

Post-curing Method |

Suitable Rubber Types |

Crosslinking Effect |

Wear Resistance |

Cycle Time |

Injection Molding Compatibility |

Surface Finish |

Cost Efficiency |

| Hot Air Circulation | NBR/EPDM | Medium | Medium | Medium | Good | Medium | Medium |

| Microwave Post-curing | FKM/VMQ | High | High | Fast | Excellent | High | High |

| Hot Oil Immersion | NR/CR | Low | Medium | Slow | Fair | Low | Low |

| Hot Press Sealed Cavity | HNBR/EPDM | High | High | Medium | Excellent | High | Medium |

How does post-curing benefit seal quality in injection molding?

In rubber-plastic hybrid parts, post-curing not only strengthens the rubber but also ensures a more stable interface with molded plastic parts. Especially in overmolded products, controlled post-curing prevents lip tearing or dislocation.Post-curing reinforces interface strength, ensuring reliability of injection-molded assemblies.

1.Overall Seal Structure Optimization: Improves interface bonding

2.Rubber-Plastic Integration Enhancement: Extends dual-material part life

3.Mold Fit Precision Boost: Improves conformity between lips and cavities

4.Reduced Rework Rate: Lowers complaints from early wear failures

Conclusion

Post-curing technology addresses the high-wear challenge of rubber lips while offering stable sealing solutions for the injection molding industry. A well-designed post-curing process significantly improves rubber durability under dynamic loads. Striking a balance between performance, cost, and efficiency, post-curing is becoming a critical part of modern sealing technology. Integrating it into injection molding post-processes is a key to elevating product quality.

For expert assistance in implementing post-vulcanization for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-06-2025