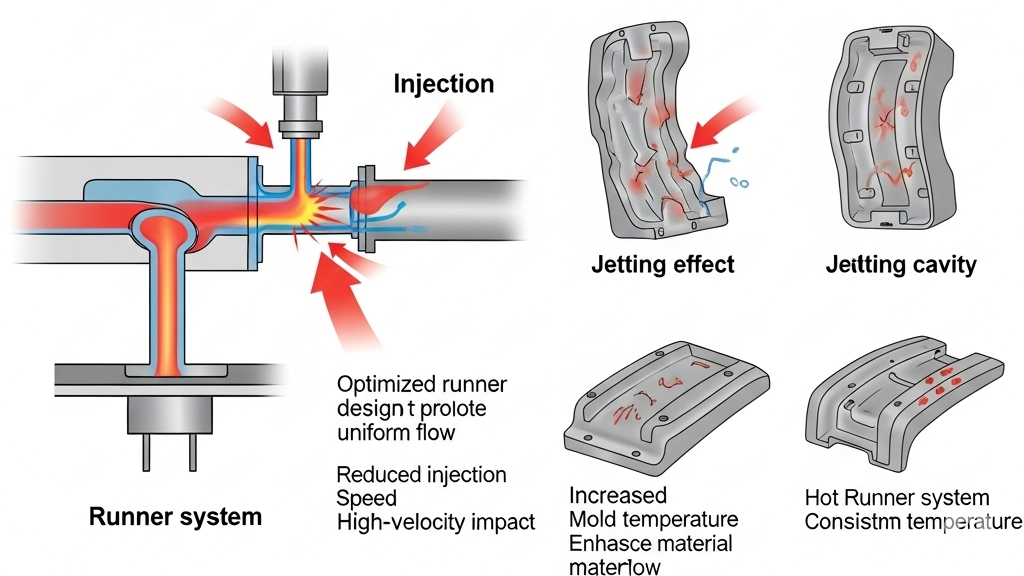

Jetting often occurs during the rapid filling phase of ABS injection molding, leading to surface defects such as snake lines, silver streaks, and uneven gloss. This is particularly problematic for thin-walled parts or poorly designed runners.Jetting directly affects the appearance and structural integrity of the product.

To enhance product quality, optimization must be carried out from multiple aspects, including material properties, process settings, and mold structure. Only through coordinated control can ABS parts maintain good aesthetics under high efficiency. Solving jetting issues is key to improving surface quality and process stability.

How to Effectively Suppress Jetting in ABS?

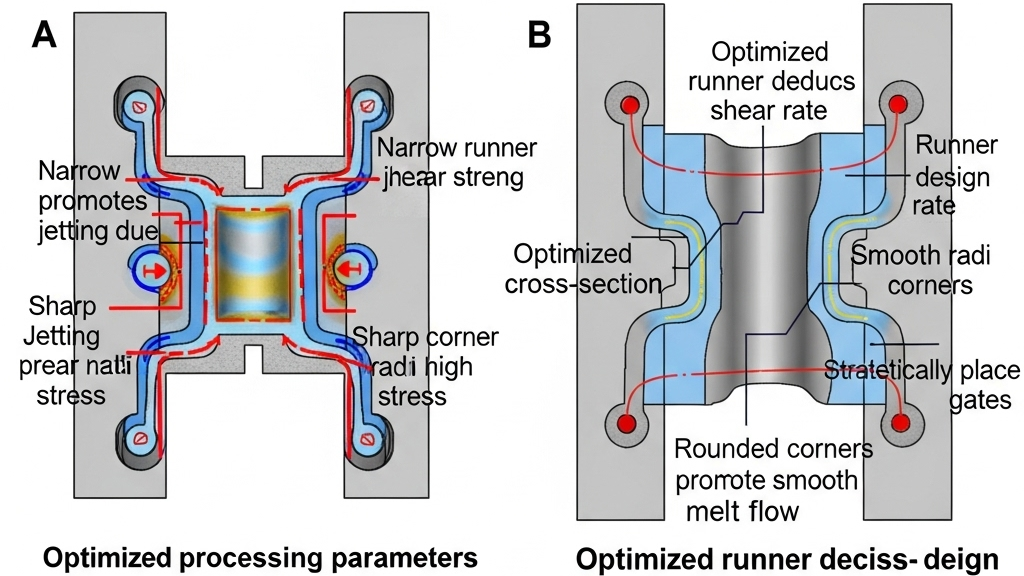

Without proper cushioning design, ABS melt may whip into the mold cavity at high speed, causing visible defects. Key influencing factors include gate design, injection speed, and mold temperature.Proper control of injection speed and back pressure helps reduce jetting.

- Lower Initial Injection Speed: Controls the melt’s entry speed to prevent snake-like flow.

- Reduce Nozzle and Gate Size: Slows down melt impact and improves stability.

- Optimize Mold Temperature: Avoids cooling-induced jetting by keeping temperature consistent.

- Fine-Tune V/P Switch Point: Reduces sudden flow changes by precise pressure transition.

How Can Mold Design Prevent Jet Marks?

Improper mold design, such as deep gates, lack of cushion zones, or straight runners, often leads to jetting. The mold structure greatly determines the melt flow path. Optimizing gate location and buffer zones is crucial to minimizing jetting.

- Use Submarine Gate Design: Controls entry angle to avoid direct impingement.

- Create Melt Buffer Zones: Reduces impact force on cavity surfaces.

- Redirect Gate Positioning: Angle or side gate breaks high-speed jetting.

- Improve Runner Layout: Balanced hot runners promote even flow.

Does ABS Material Formula Affect Jetting?

ABS’s flowability and shear sensitivity have a direct impact on jetting. High-flow grades may lead to snake marks, especially when additives are misused.Using medium-flow ABS helps maintain controllable jet behavior.

- Use Medium Flow ABS Pellets: Reduces melt impact with slower filling.

- Avoid Overusing Additives: Excess lubricants may trigger jet formation.

- Proper Release Agent Application: Poor handling alters speed and direction.

- Use ABS Alloys: ABS/PC blends offer more stable flow characteristics.

Process Strategy Comparison for Jetting Control

|

Strategy |

Injection Speed |

Mold Temp |

Flow Grade |

Gate Design |

Jetting Control |

Cost Impact |

Best Use Cases |

| High-Speed Injection | High | Low | High | Standard | Poor | Low | General housing parts |

| Slow Start + Boost Fill | Low | Stable | Medium | Optimized | Excellent | Medium | High-appearance products |

| ABS Alloy Application | Medium | Medium | Stable | Standard | Good | High | High-strength structures |

| Mold Optimization | Medium | Medium | Any | Customized | Excellent | Medium | Precision custom parts |

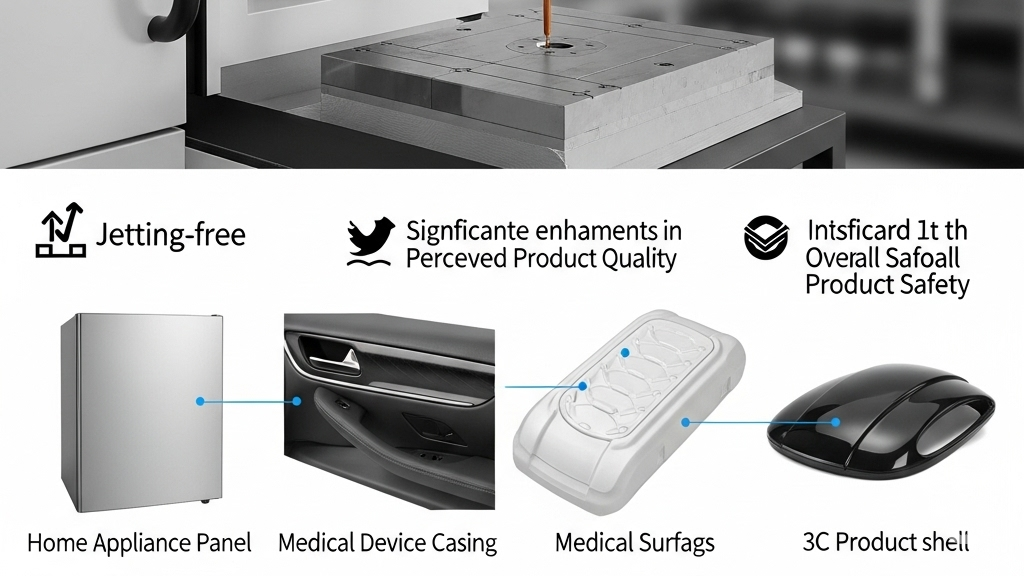

Application Expansion

With the advancement of ABS molding, jetting control becomes critical in home appliances, automotive interiors, and medical casings. Companies that upgrade design and materials gain a competitive edge.Mastering jet control is becoming a key driver of product competitiveness.

1.Home Appliance Panels: Jet-free surfaces raise acceptance rate.

2.Automotive Interiors: Glossy surfaces require zero jet marks.

3.Medical Device Casings: Jetting compromises safety and aesthetics.

4.3C Product Shells: Compact structures demand stable flow control.

Conclusion

Solving ABS jetting requires comprehensive optimization across material choice, processing parameters, and mold engineering. Establishing standardized response systems allows manufacturers to compete in high-end markets.Effective jetting control defines the visual grade and brand value of the final product.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-11-2025