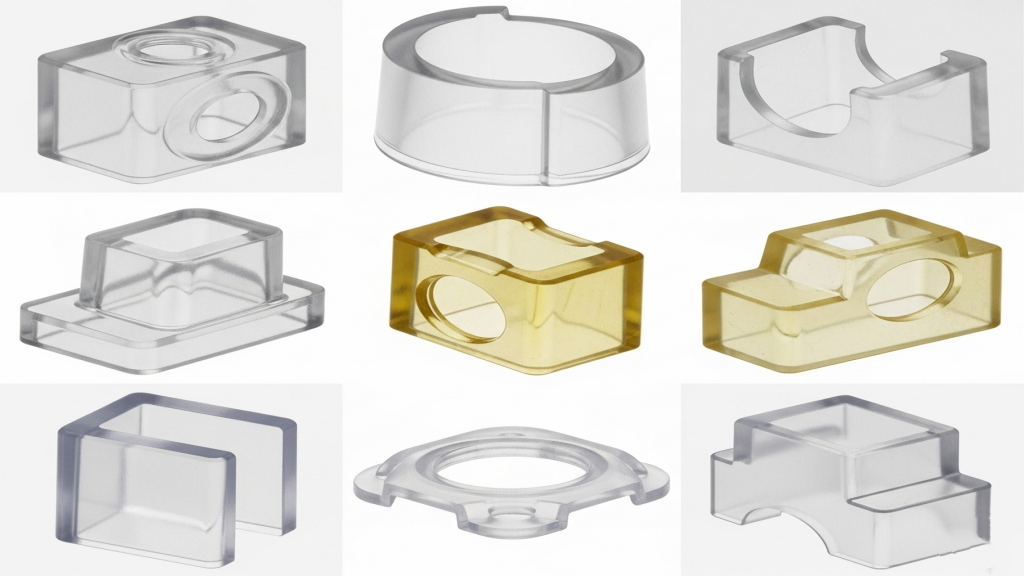

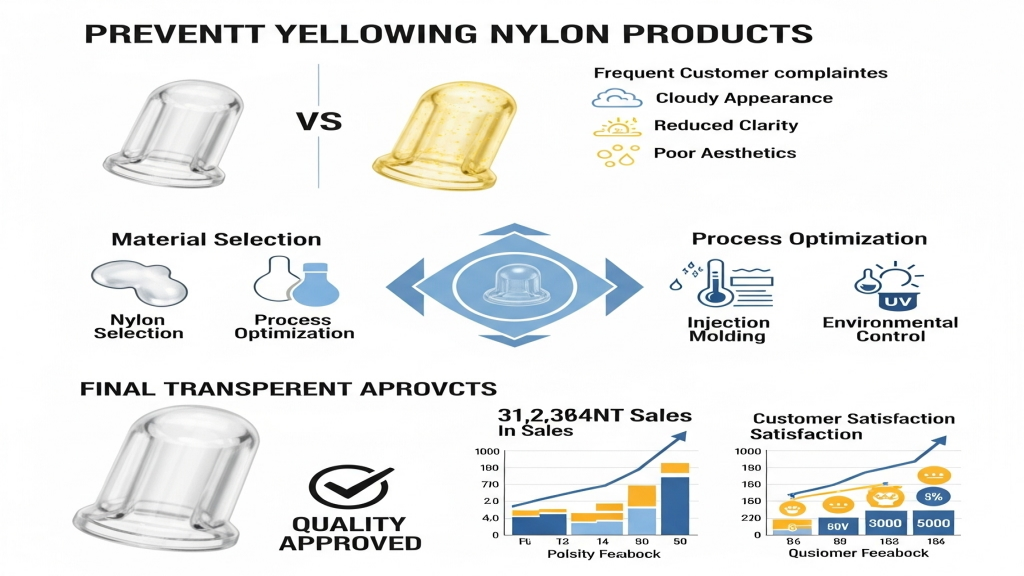

Transparent nylon is highly favored in premium sectors like medical devices and LED optics for its toughness and light transmittance. However, yellowing risks often discourage brands during mass production. Yellowing not only damages appearance but also triggers complaints and returns. Success depends on coordinated control across materials, processes, and environment.

With the rise of sustainability and high-value products, consumers are demanding stricter color clarity standards. Brands that eliminate yellowing early gain differentiation and pricing power. Through end-to-end precision management, we’ve helped clients keep yellow index within ΔYI ≤ 2, enhancing both product value and customer loyalty.

Why Is Transparent Nylon Prone to Yellowing?

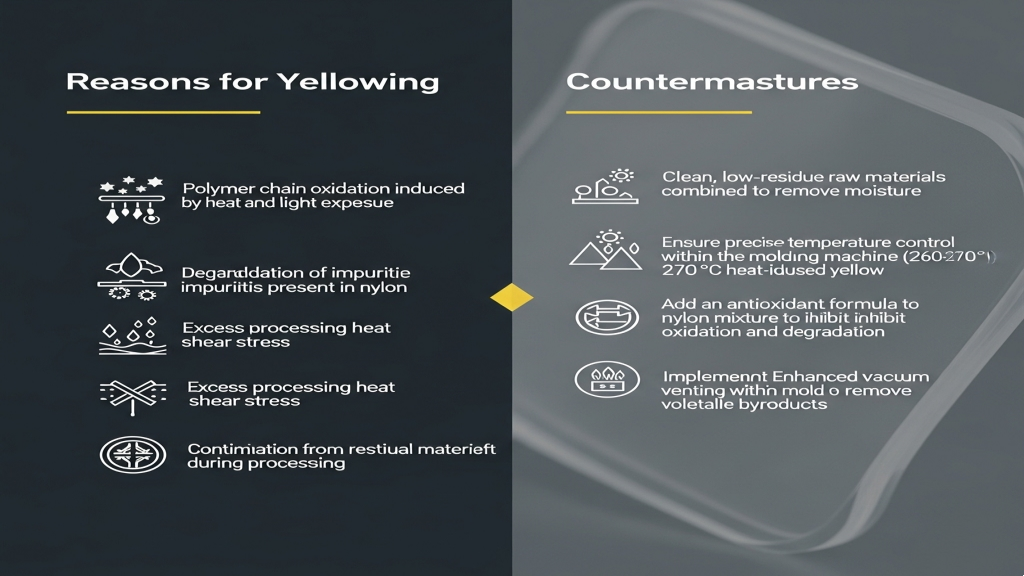

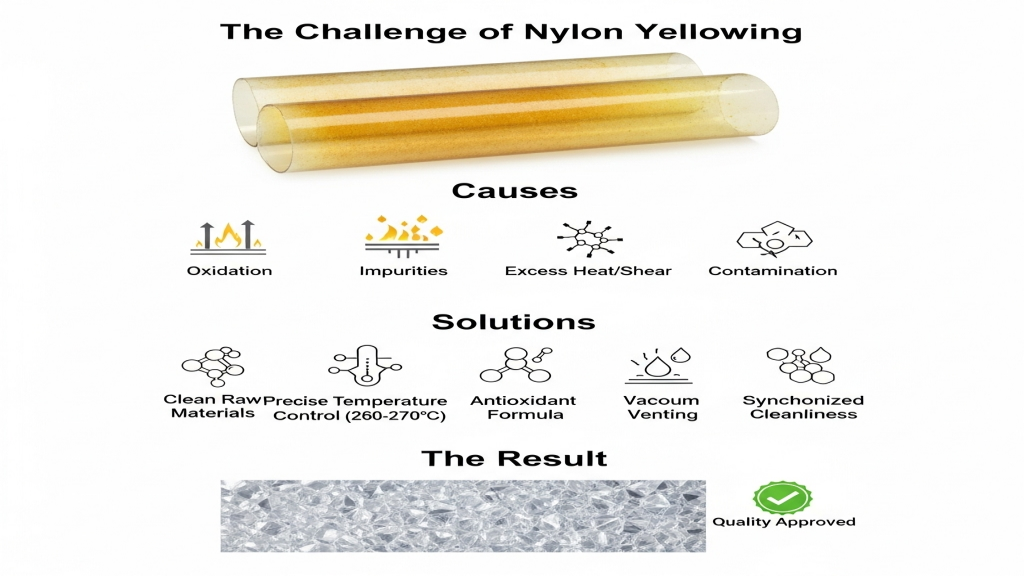

Yellowing mainly results from oxidation of polyamide chains and degradation of trace impurities. Excess heat history or high shear generates radicals around nitrogen atoms that rapidly trigger discoloration. Residual degraded material from uncleaned machines can also cause color shifts. Synchronized material and equipment cleanliness is key to yellowing prevention.

- Clean Raw Material: Use low-residue grades and vacuum-dry to reduce initial yellow tint.

- Precise Temp Control: Keep barrel zones between 260–270 °C to avoid thermal cracking.

- Antioxidant Formula: Add 0.2% hindered phenol + 0.1% phosphite to block radical chains.

- Vacuum Venting: Enhanced mold venting removes volatiles and suppresses yellowing.

How Can Mold and Process Optimization Reduce Yellowing?

Temperature control sensitivity directly affects thermal exposure time. Using multi-zone cooling with quick mold exchange can shorten cycle time by 8–12%. Lowering back pressure and screw speed helps prevent polymer degradation. Mirror-finished cavities reduce local overheating that causes color shifts.

- Multi-Zone Cooling: Maintain area temp differences within ≤ 5 °C.

- Low-Shear Injection: Set screw speed to 80–120 rpm to lower heat buildup.

- Shorter Holding Time: Optimize V–P switch to reduce melt residence time.

- Mirror Mold Surface: Achieve Ra ≤ 0.05 µm to prevent color shadows.

Can Modification and Post-Treatment Eliminate Yellowing?

Chemical modification integrates UV and antioxidant synergy for long-term weathering. Nano light stabilizer masterbatches can cut yellow index by 30% without affecting clarity. Post-mold annealing and nitrogen packaging further suppress late-stage yellowing. With lifecycle-wide quality control, outdoor clarity can be maintained crystal clear.

- Surface Coating: Solvent-free coatings form a 0.5 µm protective layer.

- Nano UV Stabilizers: Synergest® masterbatches effectively block UV-B.

- Low-Temp Annealing: 80 °C for 4 hrs rearranges internal stress and stabilizes color.

- Nitrogen Packaging: Low-oxygen packaging delays oxidation onset.

Solution Comparison Table

|

Solution |

Cost |

Yellowing Control |

Clarity Impact |

Business Value |

| Clean Raw Material | ★★☆☆ | ΔYI ≈ 3 | No Impact | Medium |

| Precise Temp Ctrl | ★☆☆☆ | ΔYI ≈ 2 | No Impact | High |

| Antioxidant Blend | ★★★☆ | ΔYI ≈ 1 | Slight Haze ↑ | High |

| UV Stabilizer | ★★★★ | ΔYI ≤ 1 | No Impact | High |

Expansion

Though the root of yellowing is chemical, the solution reflects systematic production control. For enterprises planning automated lines, integrating online color detection with MES allows real-time alerts and closed-loop tuning. When digital control meets material science, yellowing prevention evolves into value creation. This opens a path for revenue multiplication through technological leverage.

1.Online Color Monitoring: CM-700d + AI algorithm for parameter correction.

2.Smart Storage Dehumidifying: Keep dew point ≤ –40 °C to block moisture oxidation.

3.Closed-Loop Packaging: Reduce packaging costs per unit by 30%.

4.Global Tech Partnerships: Co-develop custom transparent nylon with suppliers.

Conclusion

Yellowing in transparent nylon injection molding is not unavoidable—it demands coordinated efforts in materials, processing, and post-treatment. Data-backed systematic solutions turn quality barriers into business advantages. Breaking the yellowing limit is both a technical breakthrough and a leap into the premium market. Transforming theory into scalable production is what we pursue together with our clients.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-17-2025