Introduction

During silicone injection molding, the uniformity of the vulcanization reaction directly affects the mechanical strength and surface quality of molded parts. Uneven temperature distribution, incomplete material mixing, or poor mold design may cause partial under-curing. Ensuring uniform vulcanization is the key to improving yield rate and extending mold life.

In practical production, precise mold temperature control, optimized venting design, and proper catalyst ratio can significantly reduce the risk of uneven curing. The flow behavior of silicone is closely tied to its reaction rate, and balancing these two factors ensures stable molding results. Mastering the synergy between material properties and equipment parameters is the foundation of process consistency.

What are the effects of uneven vulcanization temperature?

Temperature inconsistency across the mold is a major cause of uneven vulcanization. Areas with higher temperatures may crosslink prematurely, while cooler zones remain under-cured, leading to poor mechanical strength and visual defects. Controlling temperature precision is crucial for achieving consistent product quality.

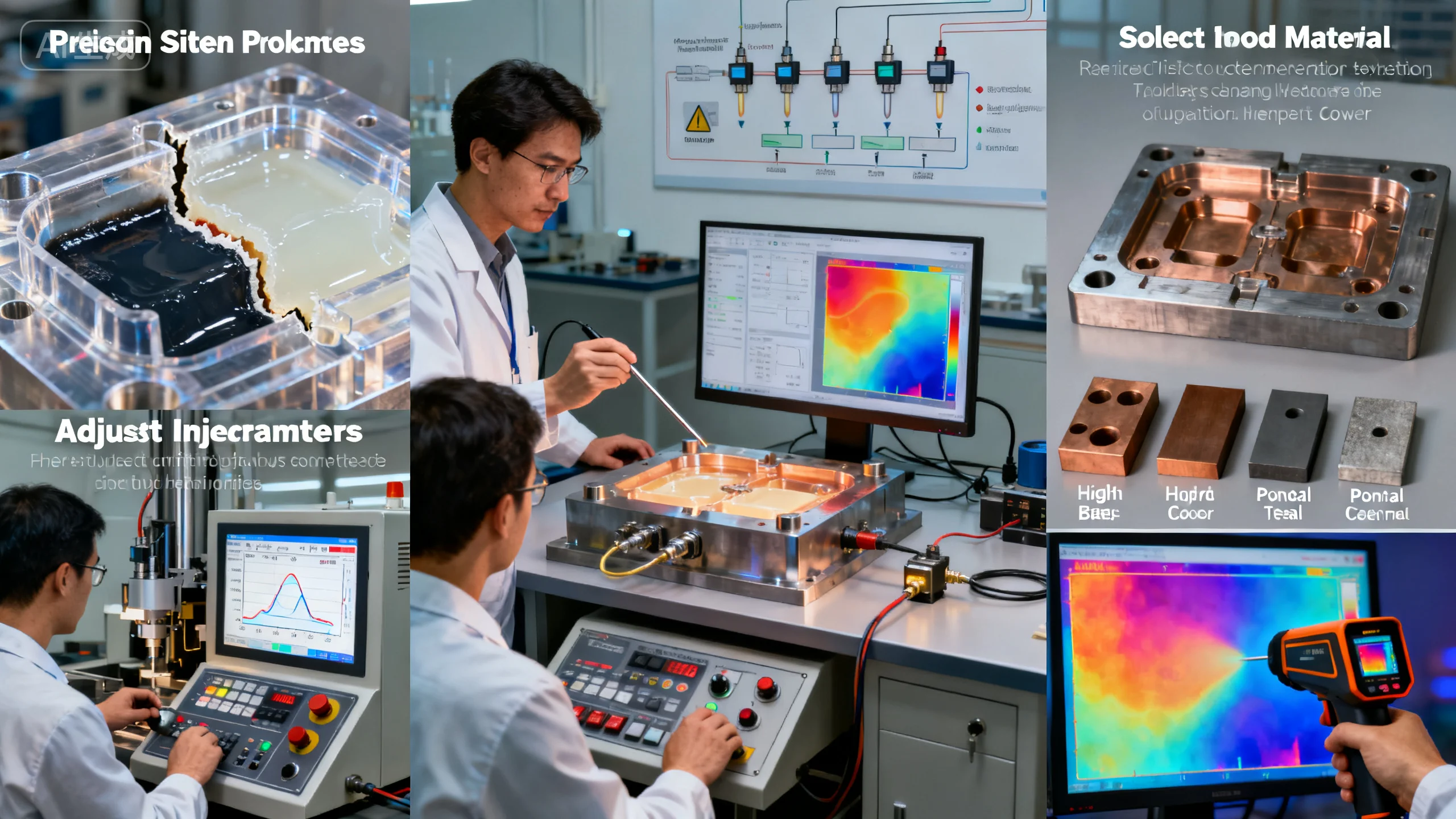

- Optimize mold temperature system: Use zone-controlled heating and thermal balancing for uniform vulcanization.

- Adjust injection parameters: Optimize injection speed and pressure to reduce thermal lag.

- Select proper mold materials: High thermal conductivity materials ensure even heat distribution.

- Use real-time temperature monitoring: Maintain stable temperature across mold zones.

Stable temperature is the first step toward eliminating uneven vulcanization.

How does improper material ratio lead to uneven vulcanization?

The ratio and uniform mixing of curing agents determine the completeness of the crosslinking reaction. Inaccurate dosing or incomplete mixing can cause over-curing in some regions and under-curing in others. Accurate measurement and thorough blending are essential for stable vulcanization results.

- Automated dosing system: Reduces human error and ensures consistent curing agent ratio.

- Efficient mixing process: Improves homogeneity within the silicone compound.

- Proper material storage: Keep materials dry and temperature-controlled to prevent degradation.

- Raw material inspection: Use viscosity and reactivity tests to detect quality variations.

Precise formulation is the foundation of uniform vulcanization.

How does mold design affect vulcanization uniformity?

Mold design elements such as runner layout, venting, and part thickness directly affect vulcanization consistency. Poor runner balance can cause material stagnation and localized overheating, leading to uneven curing. Balancing flow and venting through mold optimization is essential to eliminate vulcanization variations.

- Optimize runner design: Use simulation analysis to ensure balanced vulcanization flow paths.

- Enhance venting system: Prevent trapped gas that disrupts localized reactions.

- Adjust part thickness: Avoid thickness differences that alter curing speed.

- Improve thermal management: Promote even heat distribution throughout the mold.

Smart mold design is the structural foundation for uniform vulcanization.

Silicone Vulcanization Optimization

|

Factor |

Traditional Control |

Optimized Solution |

Performance Gain |

Cost Impact |

| Temperature Control | Manual setup | Smart temperature controller | High | Medium |

| Material Mixing | Manual blending | Automatic dosing & mixing | High | High |

| Mold Conductivity | Standard steel mold | High-conductivity alloy mold | Medium | High |

| Venting Efficiency | Single-point venting | Multi-point distributed vents | High | Medium |

Want to achieve more stable silicone molding results? contact us for tailored process optimization solutions!

From Vulcanization Control to System Integration

Uniform vulcanization is not only a matter of product quality but also reflects the integration level of your production system. From equipment configuration to data feedback, system-wide control improves predictability and reliability. Integrating vulcanization control with smart manufacturing will define the next generation of silicone injection molding.

1.Intelligent mold temperature control: Real-time data feedback enables dynamic thermal regulation.

2.Material traceability: Ensures consistent curing characteristics across all production batches.

3.Optimized mold structures: Minimizes heat concentration zones.

4.Data-driven analysis: Uses AI to predict potential vulcanization defects.

Conclusion

Controlling vulcanization uniformity in silicone injection molding is essential for producing high-quality components. Comprehensive optimization of temperature, formulation, and mold design can effectively reduce defects and extend equipment life. Digitalized and system-based control methods will become the core advantage in future silicone molding production.

For expert assistance in implementing vulcanization control for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Oct-16-2025