Introduction

PS injection molding has become a preferred choice in household appliances, consumer goods, and packaging due to its excellent transparency, low cost, and easy processability. In a highly competitive market, adopting PS injection molding helps companies quickly enhance product value and gain stronger market acceptance.

Through process optimization and innovative mold design, PS injection molding not only ensures a premium appearance but also enables efficient mass production. This allows enterprises to capture market opportunities faster and build best-selling products.

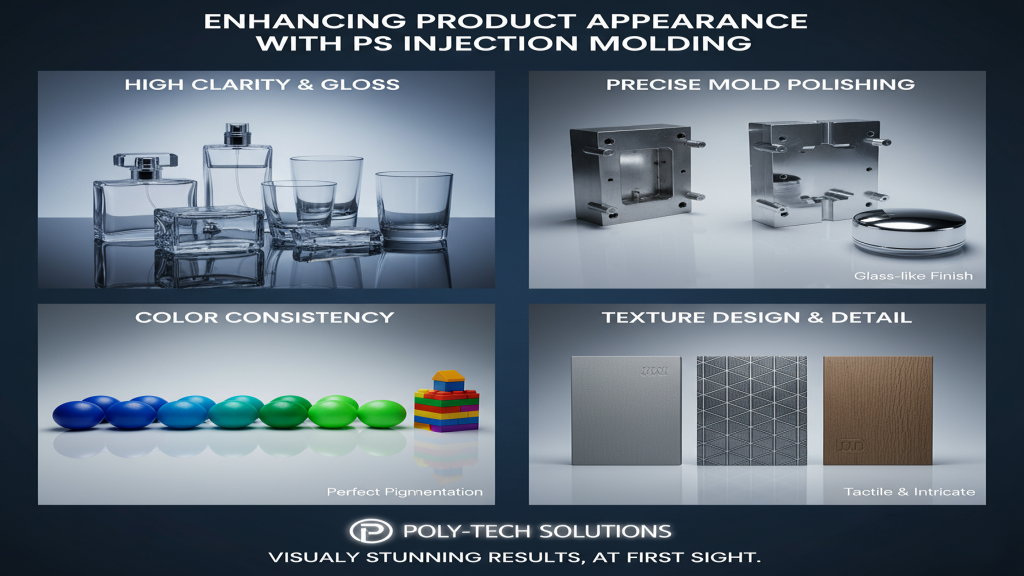

How to Enhance Product Appearance with PS Injection Molding?

In product design, appearance plays a decisive role in customer preference. With high clarity and gloss, PS injection molding allows products to achieve a visually attractive finish. By combining precise mold polishing techniques, products can achieve a glass-like look and elevate their perceived quality.

- Surface treatment: Improves gloss and clarity of transparent parts

- Color consistency: Precise pigmentation avoids color deviation issues

- Mold precision: Ensures sharp and consistent detail quality

- Texture design: Adds premium feel through surface texturing

PS injection molding makes products visually appealing at first sight

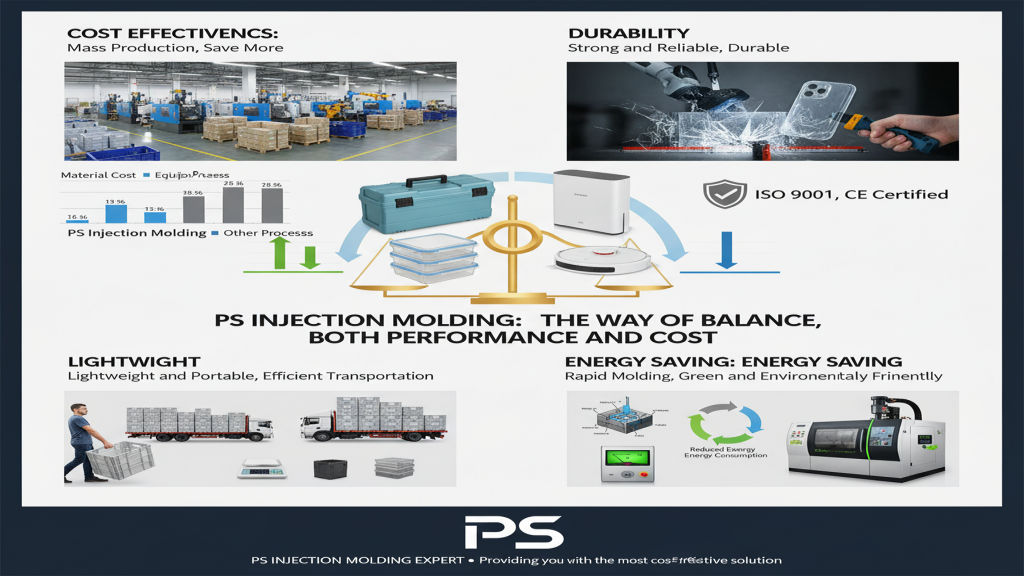

How to Balance Performance and Cost with PS Injection Molding?

The benefits of PS injection molding go beyond material affordability, as it also offers short molding cycles and high productivity. By controlling process parameters effectively, companies can reduce costs while maintaining reliable performance.

- Cost efficiency: Bulk production leads to significant savings

- Durability: Provides reliable impact resistance in daily use

- Lightweight: Reduces product weight, supporting transport and handling efficiency

- Energy savings: Faster cycles reduce overall energy demand

PS injection molding ensures cost efficiency without sacrificing performance

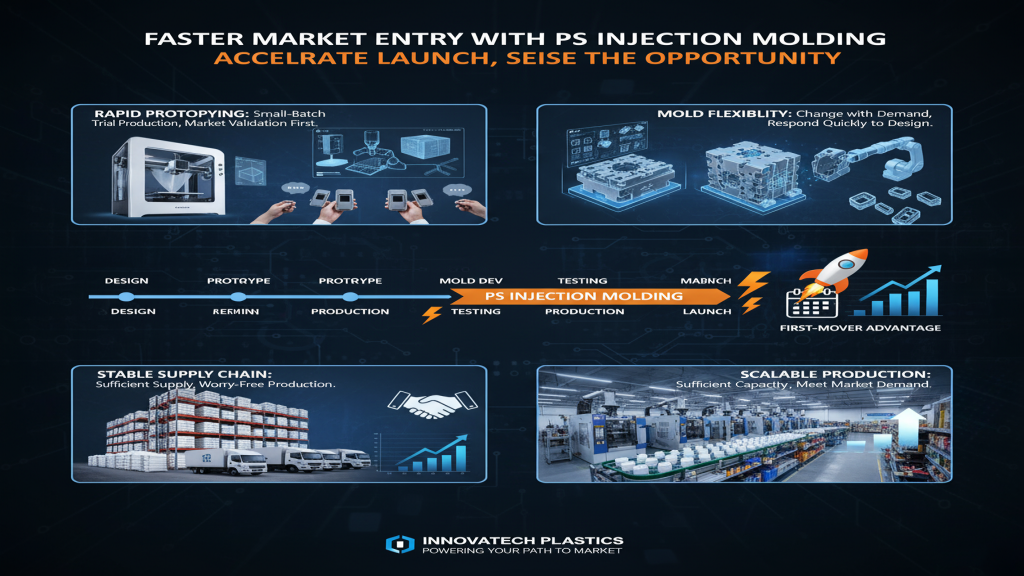

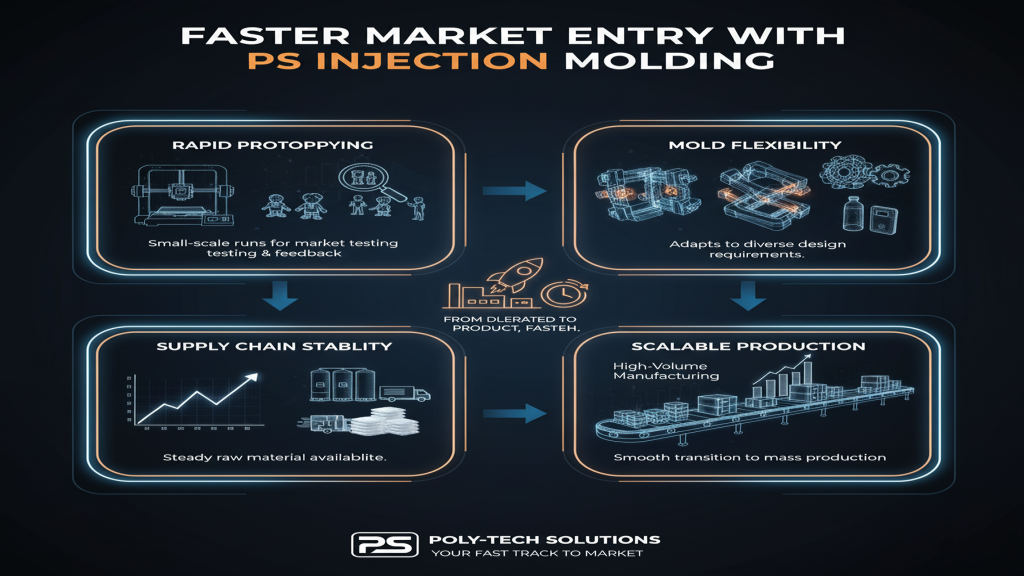

How to Enter the Market Faster with PS Injection Molding?

Speed is crucial in today’s markets, and enterprises must accelerate product launch cycles. With its mature molding process and flexible mold development, PS injection molding allows rapid validation and scalable production. This shortens the path from design to market launch, helping brands gain first-mover advantage.

- Rapid prototyping: Small-scale runs suitable for market testing

- Mold flexibility: Adapts easily to diverse design requirements

- Supply chain stability: Steady raw material availability reduces supply risk

- Scalable production: Smooth transition to high-volume manufacturing

PS injection molding enables faster time-to-market

Comparative Advantages of PS Injection Molding

|

Category |

PS (Polystyrene) |

ABS (Acrylonitrile Butadiene Styrene) |

PP (Polypropylene) |

PC (Polycarbonate) |

| Optical clarity | 88–92% light transmittance | ~70% light transmittance (mostly opaque) | Opaque, structural uses | 89–90% light transmittance |

| Material cost | ~1.2–1.6 USD/kg | ~1.8–2.2 USD/kg | ~1.0–1.3 USD/kg | ~3.5–4.0 USD/kg |

| Molding cycle | 20–40 sec | 25–50 sec | 20–30 sec | 30–60 sec |

| Typical uses | Consumer goods, packaging, clear housings | Automotive interiors, appliance housings, toys | Household items, medical consumables, pipes | Optical lenses, phone covers, industrial parts |

The Process Logic Behind Best-Selling Products

The secret behind best-selling products is not just marketing, but the material and process that back them. With its transparency, cost-efficiency, and easy moldability, PS injection molding becomes a powerful enabler across industries. Through scientific design and process refinement, companies can maximize the commercial value of PS injection molding.

1.Material benefits: Meets transparency and visual appeal demands

2.Cost control: Helps reduce total manufacturing expenses

3.Proven process: Minimizes trial-and-error costs and accelerates launches

4.Market adaptability: Supports diverse and customized needs quickly

Conclusion

PS injection molding is more than just a material option—it is a strategic tool for companies to win in fast-moving markets. It enables cost savings while delivering both performance and design appeal, ensuring faster market response. In the future, enterprises mastering PS injection molding will be more likely to launch star products.From a business perspective, PS injection molding drives not only production advantages but also product differentiation and brand competitiveness.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-11-2025