Introduction

Mold pins are the core precision components in connector molding, and their surface quality directly affects product dimensions and mold release. Poor polishing can lead to deformation or tolerance issues in connector cavities, affecting downstream assembly.

Connectors demand strict insertion force and mating precision. The finish and geometry of mold pins are critical to this. High-quality pin polishing enhances product consistency and yield, reducing rework costs.

What processing risks does surface roughness bring to mold pins?

Surface scratches or unpolished tool marks can cause rough inner bores, flash, or poor insertion life. This is especially critical for high-frequency connectors, where bore consistency is essential.

- Surface roughness affects release: Rough pins increase risk of sticking or deformation.

- Dimensional drift: Uneven flow causes eccentricity or tolerance stack-up.

- Reduced fatigue life: Burrs concentrate stress during use.

- Unstable molding cycle: Requires higher pressure or temp due to surface friction.

High-precision connectors require flawless pin surfaces for reliable performance.

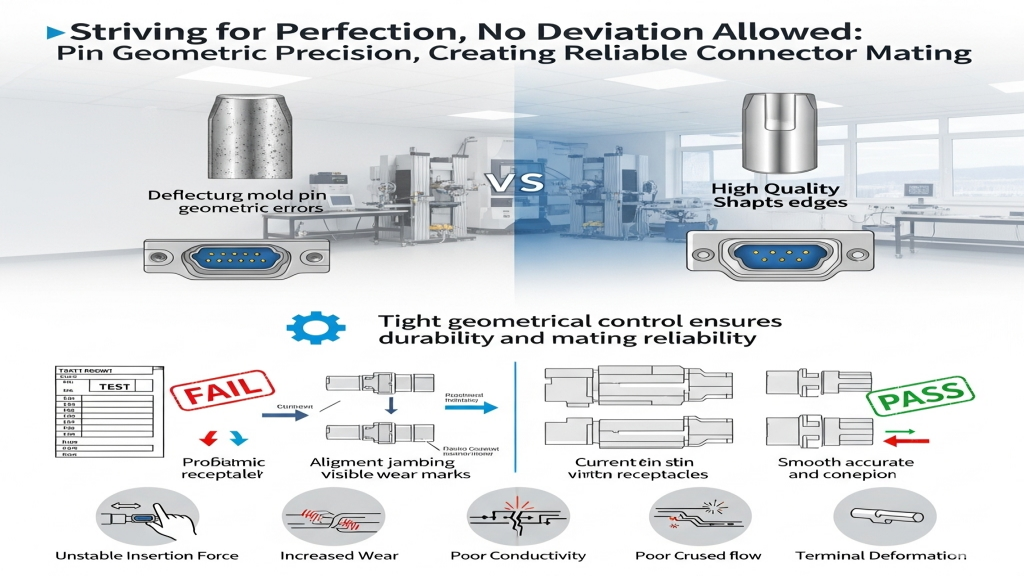

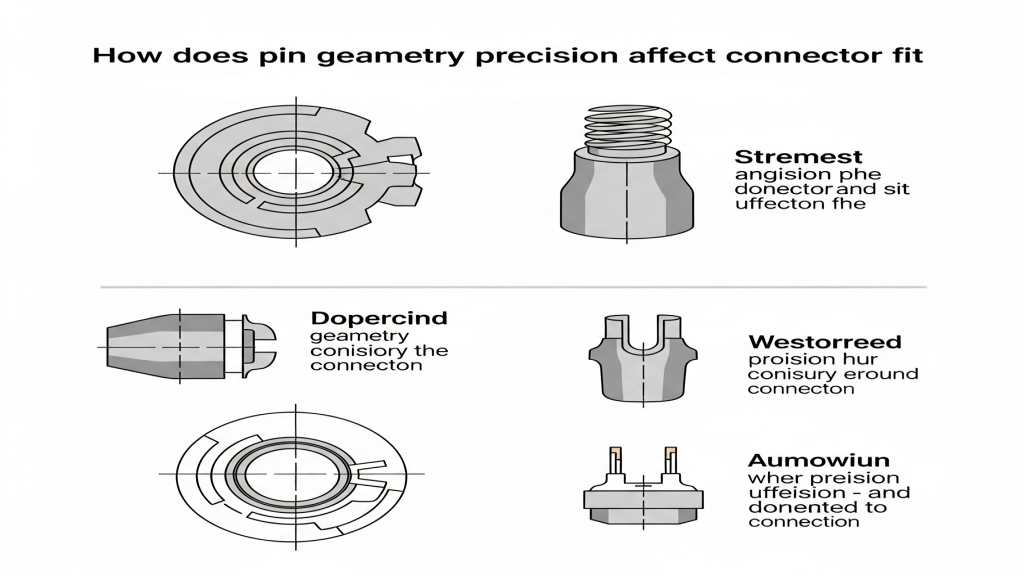

How does pin geometry precision affect connector fit?

Deviations such as ovality, taper, or eccentricity cause inconsistent mating force in terminals. Maintaining pin axial precision is key to tolerance control.

- Insertion force instability: Eccentricity leads to jamming or shallow seating.

- Increased wear: Misfit causes frictional damage during use.

- Poor conductivity: Misalignment leads to poor electrical contact.

- Terminal deformation: Uneven fit stresses metal components.

Tight geometrical control ensures durability and mating reliability.

How does polishing improve demolding and product consistency?

Polishing enhances micro-surface smoothness, reduces mold friction, and minimizes deformation or scratches during ejection. Higher polishing grades lead to smoother and more consistent bores.

- Less demolding force required: Mirror finish reduces friction.

- Minimized batch deviation: Uniform finish improves repeatability.

- Balanced stress release: Reduces residual molding stress.

- Better visual quality: Inner surfaces stay clean and undamaged.

Smooth pin finishes guarantee high-quality connector molding.

Impact of Pin Grinding Quality on Connector Products

|

Comparison |

Polished Pin |

Rough Pin |

Precise Pin |

Eccentric Pin |

| Mold Release Ease | High | Low | High | Low |

| Terminal Fit Accuracy | Excellent | Fair | Precise | Poor |

| Insertion Life | Long | Medium | Long | Short |

| Appearance Consistency | Excellent | Poor | High | Low |

How do we ensure pin grinding accuracy?

Mold pin grinding affects both mold life and product performance. We use CNC + mirror polishing to reach Ra0.2 or better for every pin.

1.High-end grinding equipment: Swiss precision 5-axis grinders.

2.ISO Process Management: Certified under ISO9001 standards.

3.Complete test coverage: CMM, profilometers, and projectors.

4.Experienced engineering team: Over 10 years in pin mold production.

Conclusion

The polishing quality of mold pins directly affects injection accuracy, mold release, and assembly performance of connectors. Precision pin grinding ensures consistent quality and reduces defect risks.

As connectors become smaller and faster, pin finishing will be even more critical. Manufacturers must improve mold details to stay competitive.

We build quality from the core, delivering precision with every mold pin we produce.

For expert assistance in implementing precision mold pin grinding for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-04-2025