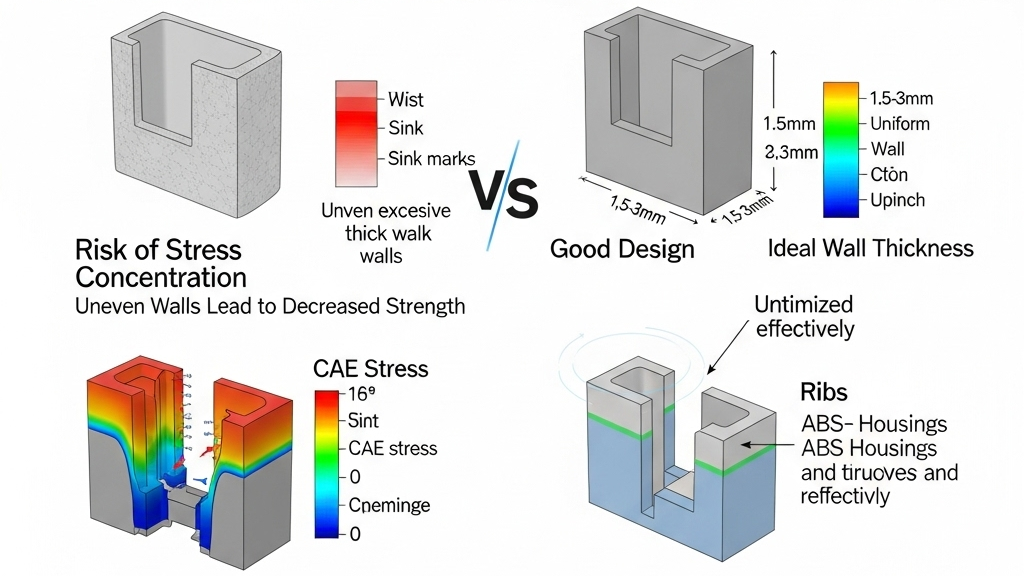

In the design of ABS injection molded parts, wall thickness is often misunderstood. Many believe that increasing the thickness means stronger structure, but reality is more complex. Improper wall thickness may lead to internal stress buildup, sink marks, and deformation.

In practical applications, wall optimization is more about structure, flow path, cooling speed, and end-use environment. Balancing functionality with manufacturability is the true design intelligence.

Does Thicker Wall Always Mean Stronger ABS?

ABS offers good rigidity and toughness, but that doesn’t mean thicker equals better. Overly thick regions in molding often result in uneven cooling, causing internal flaws.

- Design Optimization Tips: Ideal wall thickness is usually 1.5–3mm.

- Reduced Molding Efficiency: Thick walls increase cooling time and cycle.

- [Strength Misconception](- **CAE Simulation: Analyze flow and cooling in software.)**: Strength comes from ribs and structures, not just thickness.

- Risk of Stress Concentration: Sudden thickness changes lead to defects.

How to Determine Whether Wall Thickness Is Reasonable?

Molded part design quality depends heavily on the control of wall thickness. Different use cases demand different thicknesses; excessive “safety margins” often introduce defects.

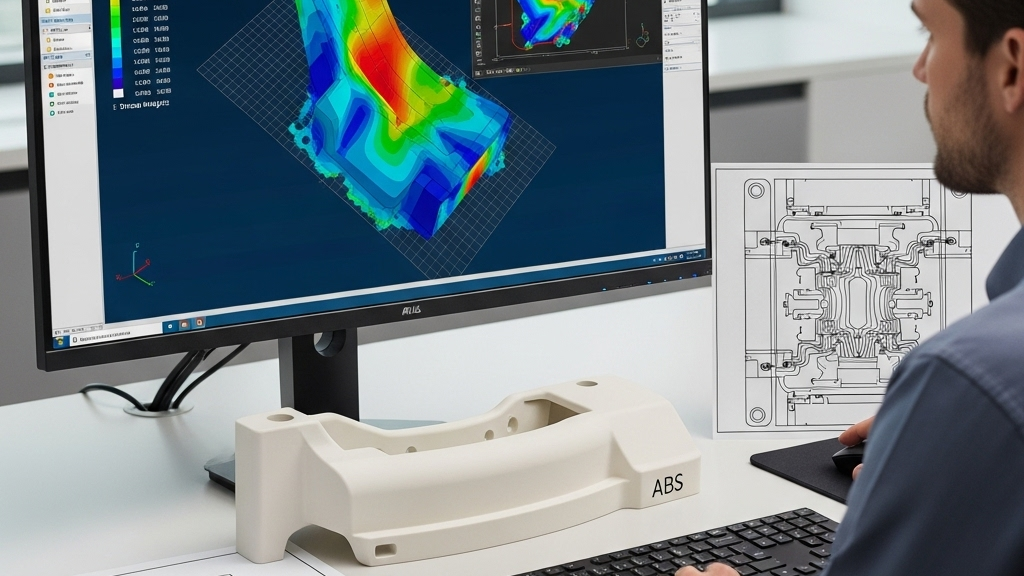

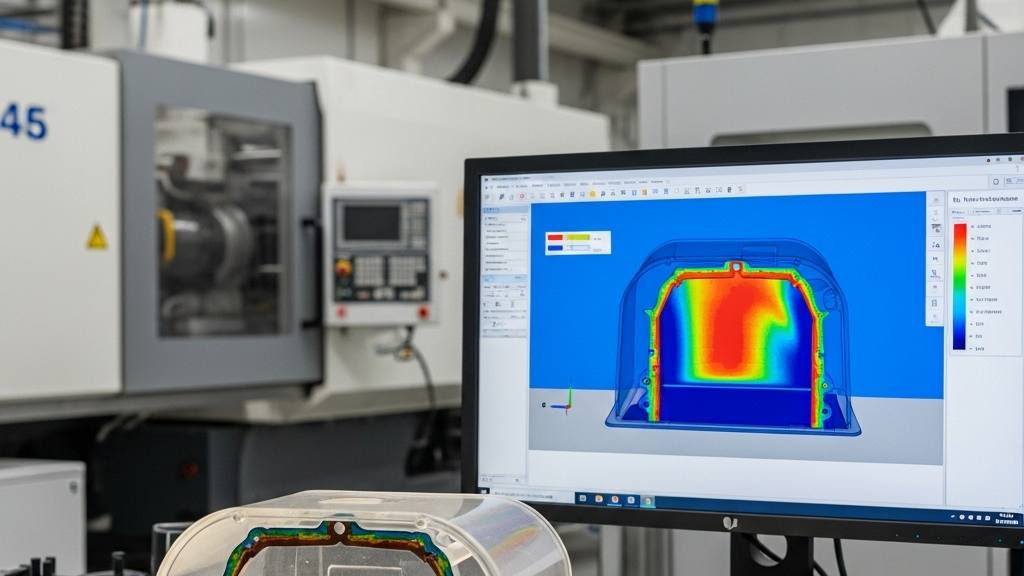

- CAE Simulation: Analyze flow and cooling in software.

- Moldflow Assistance: Use moldflow to reduce trial-and-error.

- Structural Rib Reinforcement: Strengthen with ribs rather than thicker walls.

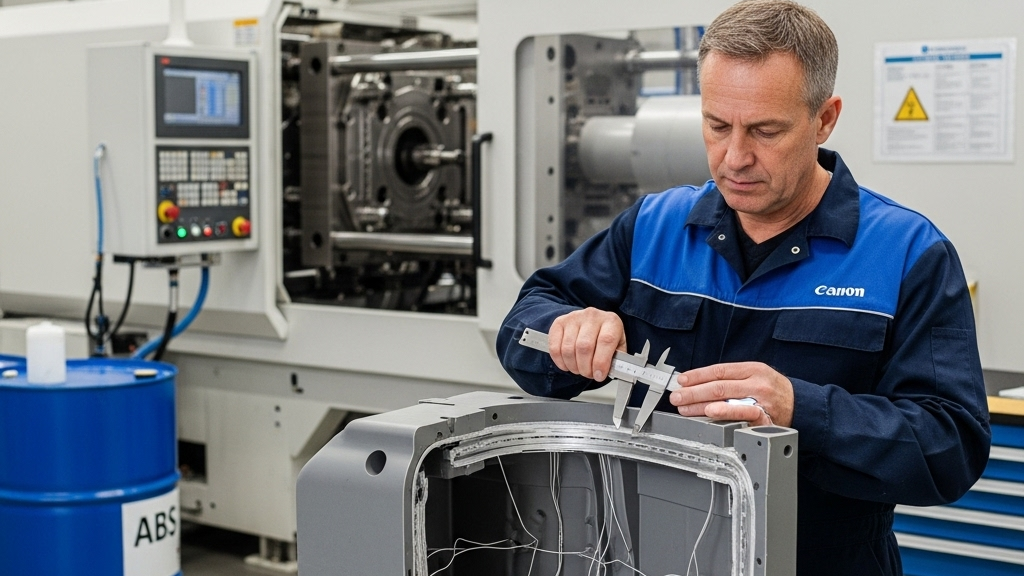

- Experience-Based Benchmarking: Compare with similar products.

Is There a Universal Wall Thickness for ABS Parts?

There’s no one-size-fits-all rule for ABS part thickness. Wall thickness should be customized based on functionality, process constraints, and environmental use.

- Industry Guidelines: ~2mm is recommended in most cases.

- Dimensional Control: Proper thickness improves fit and assembly.

- Functionality First: Structural components may require special adjustment.

- Avoid Thickness Jumps: Sudden transitions create weld lines and stress points.

There’s no one-size-fits-all rule for ABS part thickness. Wall thickness should be customized based on functionality, process constraints, and environmental use.

- Industry Guidelines: ~2mm is recommended in most cases.

- Dimensional Control: Proper thickness improves fit and assembly.

- Functionality First: Structural components may require special adjustment.

- Avoid Thickness Jumps: Sudden transitions create weld lines and stress points.

Wall Thickness Impact on ABS Molding

|

Parameter |

Too Thin |

Recommended (2mm) |

Too Thick |

Very Thick (>4mm) |

| Cycle Time | Fast but shrinks | Balanced | Longer | Much longer |

| Surface Quality | Warps easily | Excellent | Sink marks | Severe sink marks |

| Structural Integrity | Brittle | Stable | Internal stress | Voids/cracks risk |

| Cost Control | Low but high scrap | Economic | Higher cost | Very high cost |

Other Key Considerations in Wall Design

Wall thickness is just one of many critical design factors in ABS molding. Proper flow channels, ejection angles, venting, and cooling systems are equally essential. Integrated mold design is key to part quality and production efficiency.

1.Flow Balance: Uniform thickness helps maintain even melt flow.

2.Draft Angle Reserve: Thick walls may require extra draft angle.

3.Venting Optimization: Thick regions trap gas—need proper vents.

4.Enhanced Cooling: Thick zones need dedicated cooling channels.

Conclusion

Wall thickness is not simply “the thicker the better.” It’s a critical design variable that requires balance among strength, manufacturability, and cost. Precise control of wall thickness is central to better product performance and efficient production.

For expert assistance in implementing wall thickness optimization for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jun-23-2025