Introduction

Overmolding technology helps companies validate designs during the R&D stage and accelerate time-to-market. This service not only saves valuable time but also provides customers with a competitive edge. By optimizing mold design and processing parameters, repetitive trial-and-error steps are significantly reduced.

In today’s competitive market, Overmolding provides flexibility and enables multi-functional integration. This means manufacturers can respond quickly to market needs and deliver higher-value products.

How Does Overmolding Shorten Development Cycles?

In injection molding, Overmolding allows multiple functions to be integrated into one part, reducing the need for additional assembly steps. This not only improves production efficiency but also significantly lowers development risks. As a result, customers can transition from design to mass production much faster.

- Efficiency Boost: Integrated steps streamline pilot runs to full production

- Cost Optimization: Fewer molds and parts reduce overall expenses

- Quality Control: Eliminates errors caused by repeated assembly

- Flexible Design: Enables structural and aesthetic combinations across materials

Overmolding accelerates development and helps businesses capture market opportunities.

How Does Overmolding Balance Function and Appearance?

Overmolding not only enhances part strength but also elevates surface texture and visual appeal. By selecting suitable overmolding materials, products can meet functional requirements while increasing aesthetic value. This ensures stronger differentiation in competitive markets.

- Aesthetic Upgrade: Greater variety in surface textures and color choices

- Function Integration: Mechanical and protective performance improved simultaneously

- Improved Tactility: Soft-touch materials create a more comfortable experience

- Brand Value: Enhances product recognition and premium feel

Overmolding combines function and beauty, creating products with greater competitiveness.

How to Ensure Strong Bonding in Overmolding?

Selecting the right substrate and overmolding material is critical. If material compatibility is insufficient, bonding strength may drop, affecting product performance. With precise mold design and process control, consistency and reliability can be greatly improved.

- Process Optimization: Accurate control of molding temperature and pressure

- Material Selection: Pairing highly compatible substrates and overmold materials

- Structural Design: Mechanical interlocks boost bonding strength

- Surface Treatment: Improves adhesion between substrate and overmold

Strong bonding is the cornerstone of successful Overmolding.

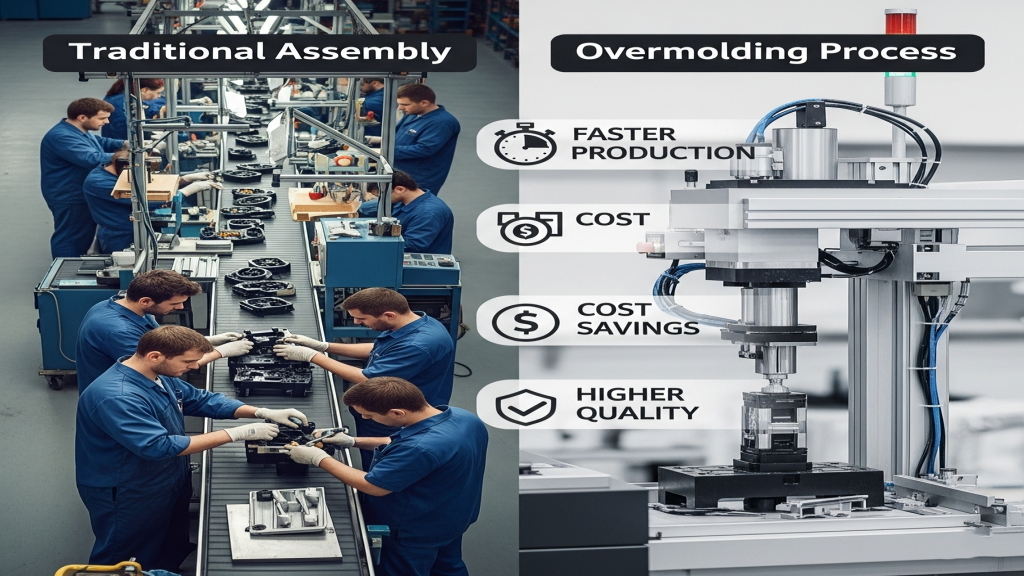

Overmolding vs. Traditional Injection Molding Development

|

Item |

Overmolding Development |

Traditional Injection |

Cost Advantage |

Speed to Market |

| Process Steps | Fewer | More | High | Fast |

| Design Flexibility | High | Medium | High | Moderate |

| Assembly Risk | Low | High | High | Slow |

| Aesthetic Integration | Strong | Medium | High | Moderate |

How Does Overmolding Support Rapid Mass Production?

Overmolding services not only streamline early-stage development but also bring strong advantages in mass production. During batch production, consistency and efficiency reduce defect rates and stabilize production lines. This allows companies to meet diverse market demands with lower overall costs.

1.Consistent Output: Ensures reliable parts in large-scale production

2.Cost Sharing: Economies of scale reduce per-unit cost

3.Supply Chain Efficiency: Fewer assembly steps shorten lead times

4.Adaptability: Enables quick design adjustments for customization

Conclusion

Overmolding services have become a vital enabler of fast development and efficient manufacturing. They not only accelerate R&D cycles but also add value through design flexibility and material optimization. For companies aiming to stay ahead in a crowded market, partnering with a professional Overmolding provider is essential. Looking ahead, as materials and technologies evolve, Overmolding will continue to unlock greater potential across industries.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-02-2025