Introduction

Coordinate grinding and EDM (Electrical Discharge Machining) each have their place in modern manufacturing, but in high-precision mold and component machining, coordinate grinding stands out for its stability and micron-level accuracy. Especially in applications requiring repeatable positioning and tight geometric tolerances, it outperforms.It ensures machining accuracy while significantly shortening processing cycles.

As advanced manufacturing pushes for “zero-error” tolerances, demands like non-thermal impact, mirror-level surfaces, and micro-gap control are becoming new benchmarks. Coordinate grinding avoids thermal distortion and electrode preparation, making it ideal for meeting these needs.Its cold machining approach offers a reliable solution for heat-sensitive material processing.

Why does coordinate grinding achieve higher precision?

Coordinate grinding utilizes a precision CNC system, micro-grinding head, and XYZ-axis movement to control deviations within microns. It is especially suited for complex contours and intersecting holes. Its non-contact nature eliminates mechanical stress typically found in conventional machining.

- Precision Control: Coordinate measuring systems enable 0.001mm repeatability.

- Low Thermal Impact: No heat input during grinding, minimizing material deformation.

- No Electrodes Required: Saves time on electrode design and replacement.

- Great for Hard/Brittle Materials: Ceramic grinding methods allow precise machining of non-metals.

Coordinate grinding excels in micron-level dimensional control.

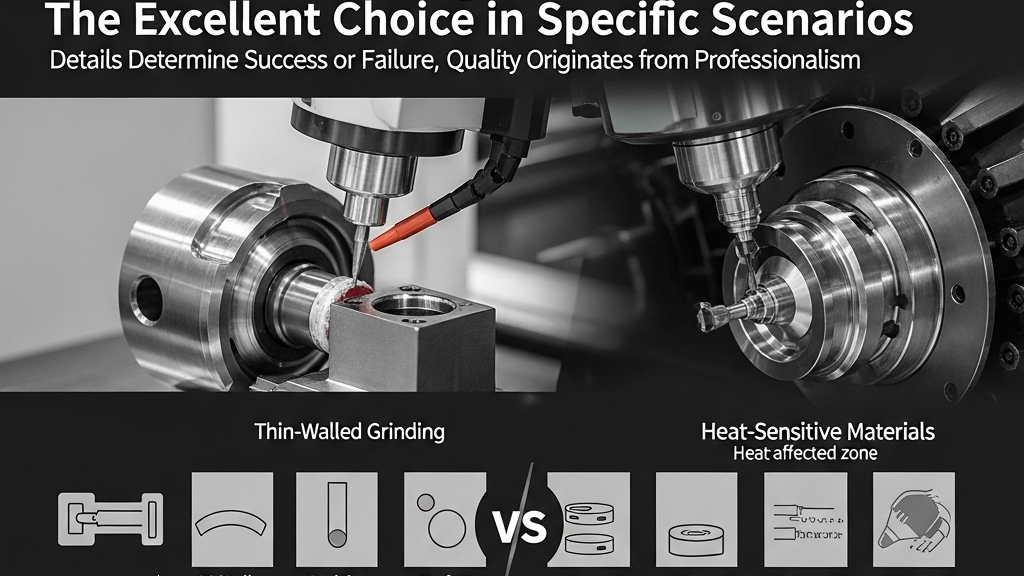

In which scenarios is coordinate grinding better than EDM?

In cases involving thin walls, precision holes, or complex surfaces, coordinate grinding provides superior control due to its non-thermal, non-eroding approach. For critical surfaces that cannot tolerate spark erosion, coordinate grinding is the top choice.

- High-Precision Holes: Micro-hole applications demand excellent tolerance control.

- Heat-Sensitive Materials: Materials like titanium and nickel alloys are better suited for grinding.

- Avoids Secondary Processes: No need to remove recast layers like in EDM.

- Mirror-Like Finishes: Achievable in a single grinding pass.

Coordinate grinding meets stricter surface and tolerance demands.

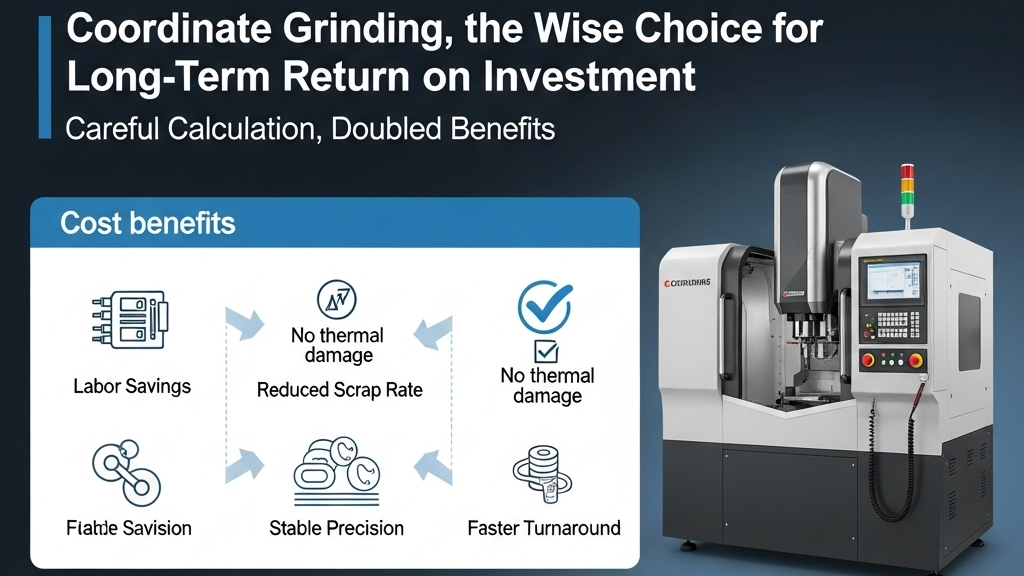

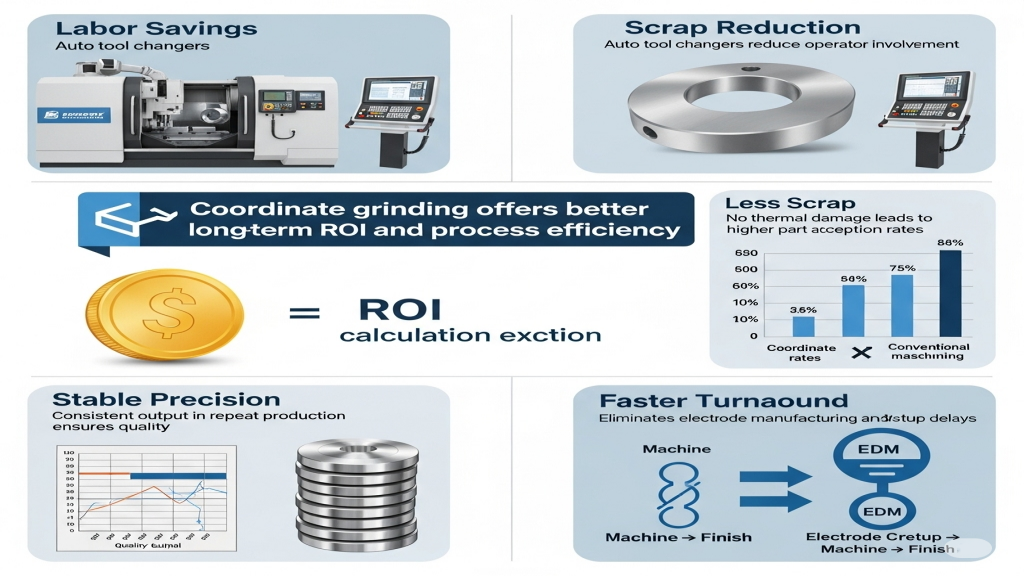

How do you evaluate the cost-effectiveness of coordinate grinding?

Though coordinate grinding equipment may cost more upfront, it offers long-term savings in labor, process steps, and rework—especially in small batch and custom part manufacturing. Considering cycle time and scrap rate, its per-part cost is often more competitive.

- Labor Savings: Auto tool changers reduce operator involvement.

- Less Scrap: No thermal damage, leading to higher part acceptance rates.

- Stable Precision: Consistent output in repeat production.

- Faster Turnaround: Eliminates electrode manufacturing and setup delays.

Coordinate grinding offers better long-term ROI and process efficiency.

Coordinate Grinding vs. EDM

|

Comparison Criteria |

Coordinate Grinding |

EDM (Electrical Discharge Machining) |

| Thermal Effect | No thermal effect, ideal for heat-sensitive materials | Thermal input present, may cause deformation |

| Surface Roughness | Ra 0.1~0.3, mirror-like finish | Ra 0.4~1.6, relatively rough |

| Precision Level | ±1μm ultra-high precision | Typically ±5~10μm |

| Electrode Requirement | No electrode needed | Requires design and replacement of electrodes |

| Material Compatibility | Wide range, especially for hard/brittle materials | Performs better with conductive metals |

| Micro-hole Capability | Excellent, high hole precision | Easily deformed due to spark erosion |

| Cost Efficiency | High efficiency, low rework rate | Higher cost due to electrode manufacturing |

| Processing Time | One-pass shaping, shorter cycle | Multi-step, longer lead time |

How does coordinate grinding affect mold design strategy?

In high-end mold development, EDM often requires compensation for thermal distortion and electrode loss, leading to lengthy processes. Coordinate grinding, however, allows direct final-shape machining. This simplifies mold structure and reduces the fitting and adjustment period.Its direct machining capability enables more simplified and accurate mold designs.

1.Simplified Design: No need to reserve electrode profiles.

2.Structural Optimization: Enables finer, more compact features.

3.Tighter Tolerances: Better mating between mold inserts.

4.Faster Processing: No secondary finishing or corrections needed.

Conclusion

As the industry pushes for tighter tolerances and consistent part quality, coordinate grinding is becoming a cornerstone of advanced CNC machining. Its cold machining nature unlocks capabilities not achievable through thermal methods.From quality and versatility to cycle speed, coordinate grinding outperforms EDM in many critical scenarios.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-22-2025