Introduction

Gas-assisted injection molding demonstrates clear advantages in HDPE product manufacturing by addressing issues such as uneven wall thickness and surface defects. This process not only enhances product quality but also reduces material and energy costs for manufacturers.

With proper mold design and process control, gas-assisted molding is especially effective for hollow, thick-walled, or complex HDPE structures. For customers seeking lightweight solutions combined with high strength, this technology is a key driver of competitiveness.

How does gas-assisted injection improve HDPE product quality?

By introducing internal gas to form hollow channels, stress within the HDPE product is evenly distributed. This technology eliminates common defects like sink marks and warpage, ensuring excellent surface and structural performance.

- Sink mark reduction: Prevents visible surface defects.

- Dimensional stability: Ensures uniformity in complex geometries.

- Lightweight strength: Uses less material without compromising durability.

- Smooth surface: Delivers a clean and appealing product finish.

By solving defects, gas-assisted molding makes HDPE products more market-ready.

How does gas-assisted injection help reduce HDPE production costs?

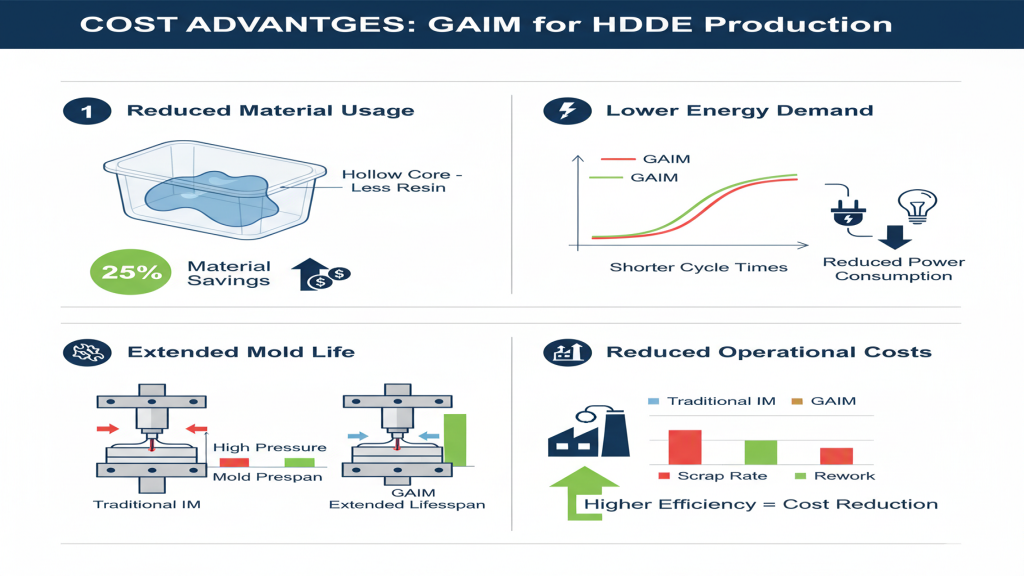

During production, gas-assisted injection lowers material usage and injection pressure. This allows companies to save on resin consumption while cutting energy usage and reducing equipment wear.

- Material savings: Significantly reduces resin usage.

- Lower energy demand: Shorter injection and cooling cycles.

- Extended mold life: Minimizes high-pressure damage to molds.

- Reduced operational costs: Lowers scrap rate and rework frequency.

Cost reductions provide businesses with strong price and efficiency advantages.

How does gas-assisted injection enhance design flexibility in HDPE products?

This process makes it possible to achieve product geometries that are difficult with traditional molding, such as hollow handles or reinforced ribs. The resulting design freedom enables products that combine strength, reduced weight, and attractive aesthetics.

- Complex shapes: Meets challenging geometry requirements.

- Hollow structures: Balances lightweight properties with strength.

- Structural optimization: Enhances functional performance.

- Design innovation: Enables customized, market-differentiated products.

Design freedom gives HDPE products broader application possibilities.

Gas-Assisted vs. Traditional Injection in HDPE

|

Feature |

Gas-Assisted Injection |

Traditional Injection |

Customer Benefits |

Typical Applications |

| Material Use | High efficiency | Average | Lower production cost | Pipes, appliance housings |

| Surface Finish | Smooth and clean | Prone to sink marks | Stronger market appeal | Automotive interiors |

| Structural Performance | Lightweight, strong | Heavy and less efficient | Longer product lifespan | Industrial containers |

| Design Flexibility | Ideal for hollow/complex parts | Limited | Competitive differentiation | Handles, grips |

Why Gas-Assisted Injection Drives HDPE Innovation

Gas-assisted molding is not just a production method—it is a pathway for product innovation. It enables HDPE products to achieve a unique balance of strength, aesthetics, cost efficiency, and design freedom.

1.Industry trend: Green and energy-efficient production is a buyer priority.

2.Market demand: HDPE applications are expanding in appliances, automotive, and packaging.

3.Customer focus: Customization and lightweight designs are in high demand.

4.Business opportunity: We deliver complete solutions with proven expertise.

Conclusion

Gas-assisted injection molding for HDPE products delivers threefold value: improved quality, reduced cost, and enhanced design flexibility. This technology removes the limitations of traditional injection molding while enabling our clients to stand out in competitive markets. With our expertise and tailored services, every HDPE solution is engineered for both performance and efficiency.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-15-2025