Post-processing is crucial for polycarbonate (PC) injection molding, as it can enhance product appearance, improve performance, and meet specific application requirements. Common post-processing methods include surface treatment, heat treatment, and machining.

Surface treatment is a widely used method to improve the appearance and performance of PC products. It can impart various colors, gloss levels, and wear resistance to the products. Heat treatment is employed to relieve internal stresses and enhance dimensional stability. Machining enables precise control over dimensions and shapes.

Why is post-processing necessary after polycarbonate (PC) injection molding?

After polycarbonate (PC) injection molding, although the material itself possesses excellent properties, post-processing becomes particularly crucial to further enhance product quality and meet specific application requirements.

- Relieving Internal Stress: Post-processing, such as heat treatment, eliminates internal stresses generated during the injection molding process, improving the dimensional stability and service life of the product.

- Enhancing Surface Quality: Surface treatments, like polishing, painting, or electroplating, improve the appearance of the product, enhancing its aesthetics and durability.

- Improving Mechanical Properties: Certain post-processing methods, such as painting or electroplating, can enhance the wear resistance and corrosion resistance of the product.

- Meeting Specific Application Requirements: Post-processing enables PC products to meet the demands of various application fields, such as sterilization treatment for medical devices and anti-static treatment for electronic products.

What are the common post-processing methods for polycarbonate (PC) injection molding?

Common post-processing methods include surface treatment, heat treatment, and machining, each with its unique advantages and applications.

- Painting: Painting can provide PC products with rich colors and enhanced wear resistance.

- Electroplating: Electroplating significantly improves the surface hardness and corrosion resistance of PC products.

- Screen Printing: Screen printing offers intricate patterns and text on PC products.

- Polishing: Polishing makes the surface of PC products smoother and enhances their glossiness.

How to choose the appropriate post-processing method based on the product?

By gaining an in-depth understanding of the advantages, disadvantages, and applications of various post-processing techniques, we can select the most suitable post-processing solution for specific products to achieve optimal performance and appearance.

- Structural Components: Heat treatment (annealing) is crucial for relieving internal stresses and improving the stability and crack resistance of structural components.

- Aesthetic Parts: Painting, electroplating, and screen printing can effectively enhance the aesthetics and customization of appearance-focused parts.

- Industrial Components: Electroplating and sandblasting can improve the wear resistance and corrosion resistance of industrial components.

- Material Heat Resistance: When selecting heat treatment, the heat resistance of the PC material must be considered to avoid damage from high temperatures.

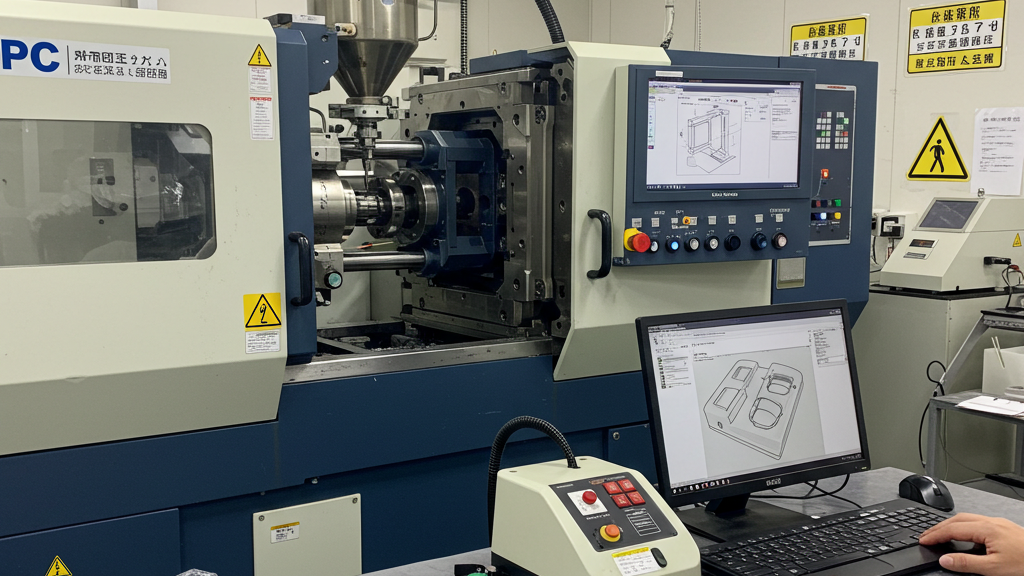

Overview of post-processing technology of PC injection molding

|

Post-processing Method |

Purpose & Effect |

Applicable Products |

Pros & Cons |

| Spraying | Change color & gloss, improve wear resistance | Appearance parts, electronic product shells | Pros: Diverse colors, significant effect; Cons: Potential for peeling |

| Electroplating | Enhance surface hardness & corrosion resistance | Electronic product shells, decorative parts | Pros: High surface hardness, corrosion resistant; Cons: High cost, potential pollution |

| Polishing | Improve surface finish & transparency | Optical lenses, transparent housings | Pros: Smooth surface, high transparency; Cons: Impacts dimensional accuracy |

| Annealing | Eliminate internal stress, improve dimensional stability | High-precision structural parts | Pros: Enhances dimensional stability; Cons: Time-consuming, high energy consumption |

Properties of Polycarbonate (PC) Material

Polycarbonate (PC), as a high-performance thermoplastic engineering plastic, is widely used in modern industries due to its exceptional physical and mechanical properties.

1.High Transparency: PC material offers excellent light transmission, making it suitable for optical applications.

2.High Strength and Toughness: PC material retains its strength and impact resistance even at low temperatures.

3.Heat Resistance: PC material maintains its performance stability across a wide temperature range.

4.Dimensional Stability: PC material preserves its shape and size under varying environmental conditions.

Conclusion

In summary, polycarbonate (PC), as a high-performance thermoplastic engineering plastic, is widely applied in modern industries due to its exceptional physical and mechanical properties.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Mar-25-2025