Introduction

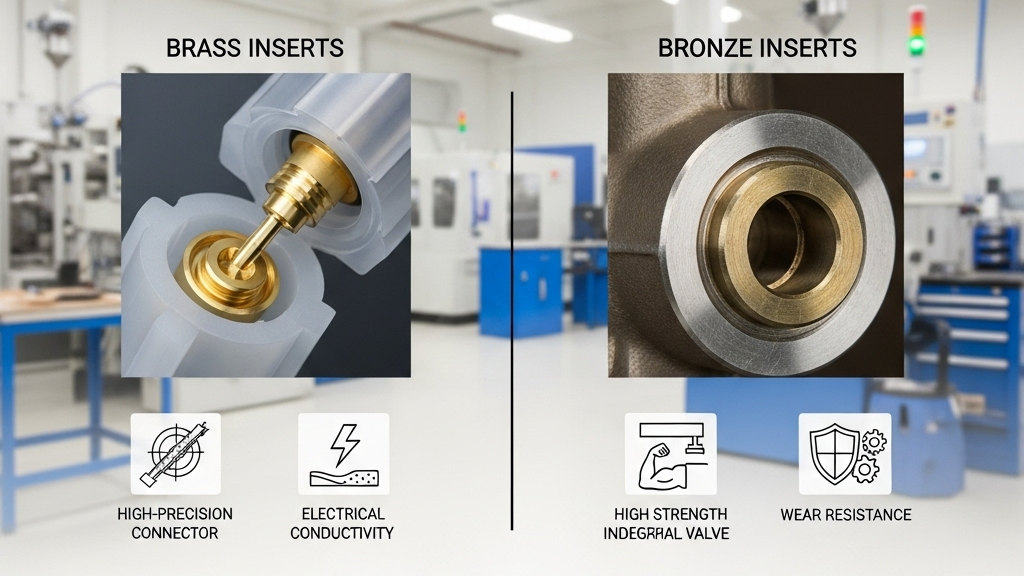

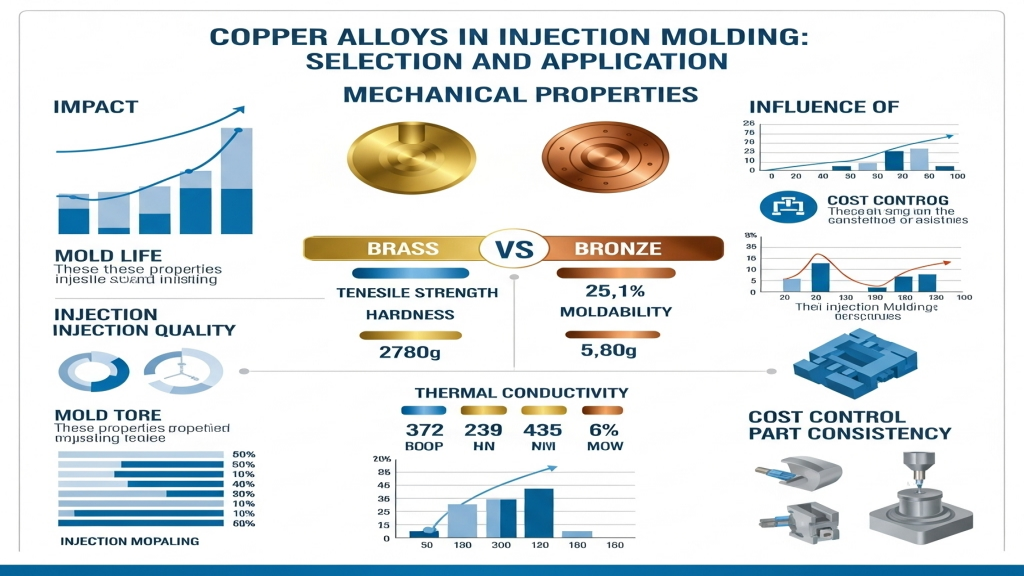

Brass and bronze, as commonly used copper-based alloys, are widely applied in connectors, valves, and decorative components in insert molding. Their mechanical properties and thermal conductivity provide a strong foundation for structural and functional integration. Choosing the right alloy significantly impacts mold life and injection quality.

Their differences in mold design, surface treatment, and processing stability affect the consistency and cost control of injection-molded parts. Moldability is the key to evaluating the practical value of brass vs. bronze.

Is brass more wear-resistant?

Brass has excellent machinability and medium hardness, making it stable for continuous mold injection. Bronze, with varying tin content, shows superior corrosion and fatigue resistance. Brass inserts help maintain dimensional precision in high-volume production.

- Mold adaptability: Brass offers better balance in mold filling and release.

- Wear resistance: Bronze performs better under pressure and repeated abrasion.

- Thermal conductivity: Brass transfers heat faster, ideal for thermal management.

- Cost-effectiveness: Brass offers lower machining cost and higher availability.

In wear-intensive scenarios, brass supports precision; bronze suits heavy-duty applications.

Does bronze offer better structural strength?

Bronze has higher tensile strength due to elements like tin or aluminum, especially enhancing performance in thin-walled parts. Brass, on the other hand, focuses on dimensional precision and batch uniformity. Bronze provides stronger mechanical support for structural reinforcement.

- Structural integrity: Ideal for high-load insert components.

- Molding complexity: Brass is easier to process for intricate inserts.

- Surface bonding: Bronze’s roughness enhances plastic adhesion.

- Thermal fatigue resistance: Bronze maintains stability under thermal cycling.

When structural and thermal reliability is key, bronze stands out.

How to choose the right copper alloy for injection molding?

Copper alloy selection impacts not just functionality but heat balance, mold durability, and compatibility with plastics. Brass works well for fast production, while bronze is ideal for load-bearing and sealing parts. The decision must balance conductivity, hardness, corrosion resistance, and cost.

- Plastic compatibility: Brass pairs well with PBT and PA-based engineering plastics.

- Plating capability: Brass suits post-molding decorative or functional plating.

- Mold wear control: Bronze extends mold life in low-friction environments.

- Mass production cost: Brass aligns with high-speed, efficient workflows.

Select alloys based on application, plastic type, and molding process requirements.

Processing Characteristics Comparison Table for Copper-Alloy Inserts

|

Property |

Brass |

Bronze |

Recommended Use |

Processing |

| Thermal Conductivity | High | Medium | Heat sinks | Easy |

| Corrosion Resistance | Average | High | Valves | Moderate |

| Tensile Strength | Medium | High | Load structures | Moderate |

| Plating Suitability | High | Average | Decorative parts | Easy |

Expansion

In injection molding, copper alloys are not limited to structural use—they’re extended through plating, insert integration, and multi-material molding. High-end automotive components and smart device interfaces often rely on brass or bronze.

1.Connection reliability: Copper alloys enhance contact stability in molded parts.

2.Aesthetic-function fusion: Molded copper parts combine visual appeal and utility.

3.Material variety: Diverse copper formulas cater to different needs.

4.Machine compatibility: Suitable machinery ensures molding precision.

Conclusion

Both brass and bronze excel in different areas of injection molding. Bronze is ideal for load and corrosion-resistance, while brass is better for batch processing and finishing. Choosing the right alloy helps differentiate products and optimize performance. The ultimate goal is to align materials and process for full-scale functional and aesthetic performance.

For expert assistance in implementing for your production needs, visit our resource center or contact us。Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Aug-05-2025