Introduction

In CNC machining, pre-machining not only determines the stability of subsequent processes but also affects the overall lifespan and accuracy of injection molds. Proper pre-machining significantly reduces material waste while improving efficiency and quality.

For mold makers, mastering scientific CNC pre-machining techniques can shorten lead times, reduce costs, and help clients quickly transition from design to mass production. This is the key for companies to stand out in a competitive market.

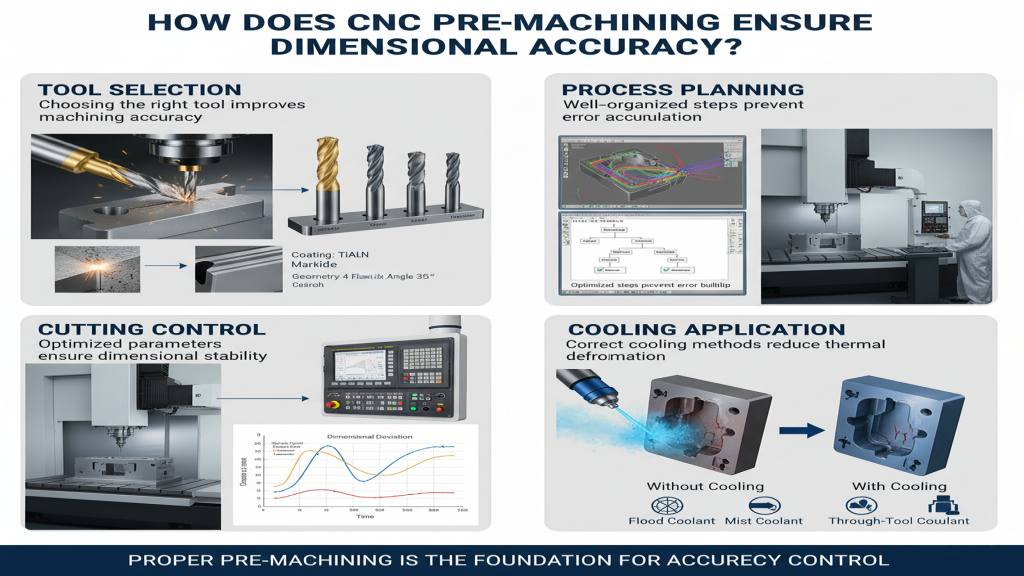

How does CNC pre-machining ensure dimensional accuracy?

In mold manufacturing, the pre-machining stage is a critical factor that affects the accuracy of the final product. With proper process planning and tool selection, deviations in later processes can be avoided. Combined with optimized cooling methods and cutting parameters, machining stability can be improved significantly.

- Tool Selection: Choosing the right tool improves machining accuracy.

- Process Planning: Well-organized steps prevent error accumulation.

- Cutting Control: Optimized parameters ensure dimensional stability.

- Cooling Application: Correct cooling methods reduce thermal deformation.

Proper pre-machining is the foundation for accuracy control.

How does CNC pre-machining minimize machining stress?

When machining mold steels, if internal stress is not released effectively, it will affect the durability of injection molds. By controlling machining allowances and applying multiple machining steps, the risk of stress concentration can be significantly reduced.

- Allowance Distribution: Proper allowances prevent deformation.

- Multiple Rough Cuts: Step-by-step machining reduces stress concentration.

- Annealing Process: Heat treatment helps release internal stress.

- Balanced Cutting: Symmetrical cutting lowers deformation risks.

Minimizing stress is key to extending mold lifespan.

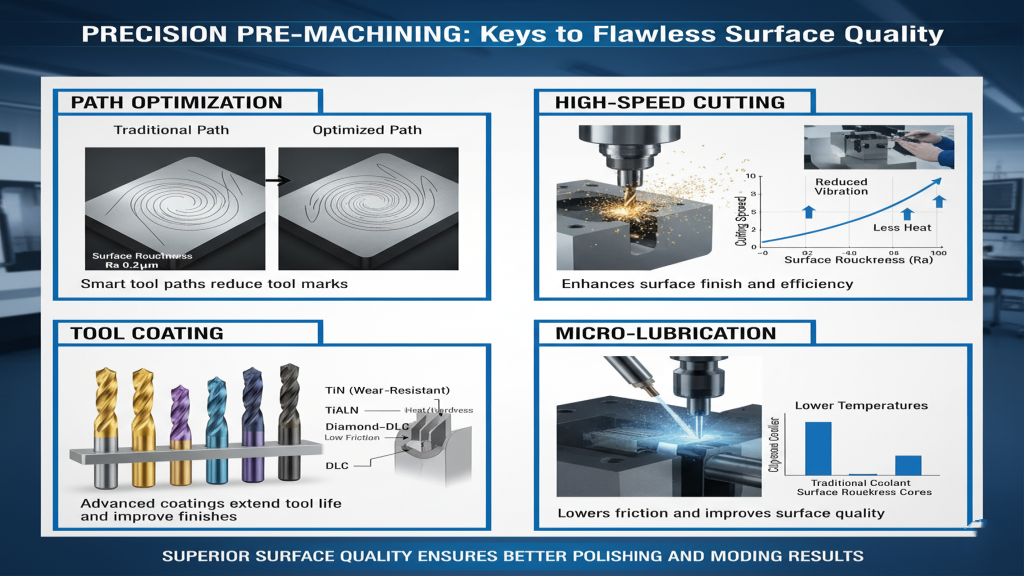

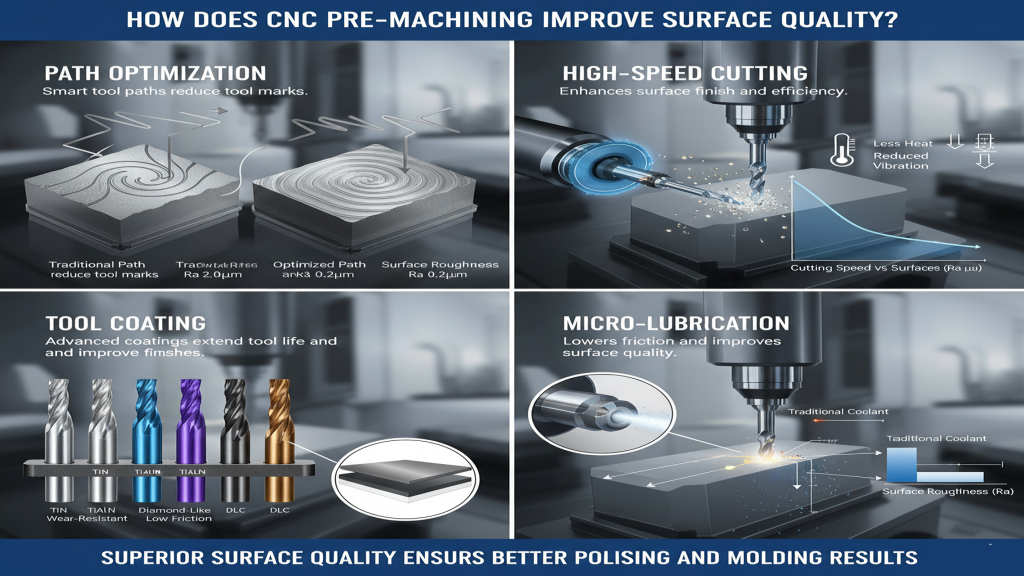

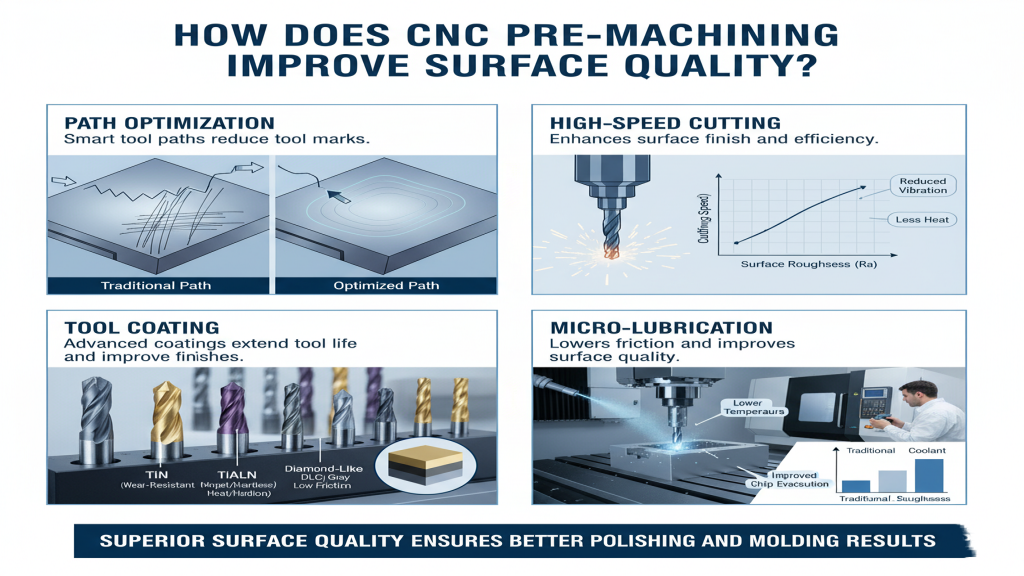

How does CNC pre-machining improve surface quality?

In mold pre-machining, surface quality directly impacts demolding performance and the final appearance of injection parts. Optimizing tool paths and adopting high-speed cutting technologies can greatly improve surface smoothness.

- Path Optimization: Smart tool paths reduce tool marks.

- High-Speed Cutting: Enhances surface finish and efficiency.

- Tool Coating: Advanced coatings extend tool life and improve finishes.

- Micro-Lubrication: Lowers friction and improves surface quality.

Superior surface quality ensures better polishing and molding results.

Key Comparison of CNC Pre-Machining

|

Technique |

Accuracy |

Stress Relief |

Surface Finish |

Cost Efficiency |

| Tool Choice | High | Medium | High | Medium |

| Process Plan | High | High | Medium | High |

| Heat Treating | Medium | High | Medium | Medium |

| High-Speed Cut | Medium | Medium | High | High |

Looking for the best CNC pre-machining solution for your molds? Get expert support today — contact us.

CNC Pre-Machining and Mold Efficiency

CNC pre-machining is more than just a process—it’s a performance booster for molds. With optimized workflows and precise control, molds can reach stable production faster. For businesses, this translates into lower maintenance costs and higher customer satisfaction.

1.Efficiency Boost: Pre-machining accelerates mold readiness for mass production.

2.Quality Assurance: Reduces defect rates and ensures consistency.

3.Faster Delivery: Optimized steps shorten lead times.

4.Customer Value: High-performance molds give businesses a competitive edge.

Conclusion

In CNC pre-machining, accuracy, stress control, and surface quality are the three core elements every manufacturer must master. By applying these techniques, businesses gain stronger competitiveness in mold making and injection production. With scientific planning and advanced technology, the process becomes more efficient and reliable. Ultimately, companies not only lower production costs but also deliver stable and high-quality products to their clients.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-23-2025