Thermosetting plastics are widely used in injection molding industries due to their excellent mechanical and heat resistance properties. However, their moisture absorption characteristics can negatively affect product quality in humid environments. Changes in moisture content directly affect dimensional stability and mechanical strength.

Products are often exposed to humid environments during transportation and use, leading to internal stress from moisture uptake that may cause cracking, warping, or failure. Buyers should evaluate the moisture resistance of materials to ensure long-term product performance.

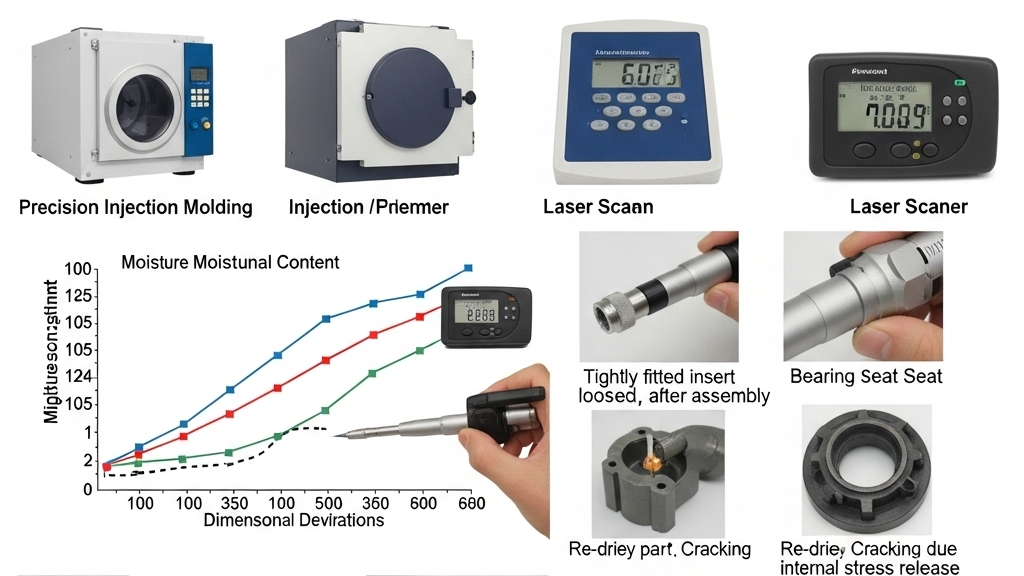

How much does moisture affect dimensions?

Higher moisture absorption causes swelling in thermoset parts, which can lead to dimensional deviation beyond process tolerance, potentially resulting in assembly issues or failures. Material instability due to moisture is now a major risk in precision part design.

- Increased dimensional errors: Even micron-level changes can cause rejection in precision parts.

- Stress-induced deformation: Re-drying leads to warping or cracks.

- Fit tolerance failures: Especially in tight-fitting insert parts.

- Stacked deviation effects: Risk amplifies during mass production.

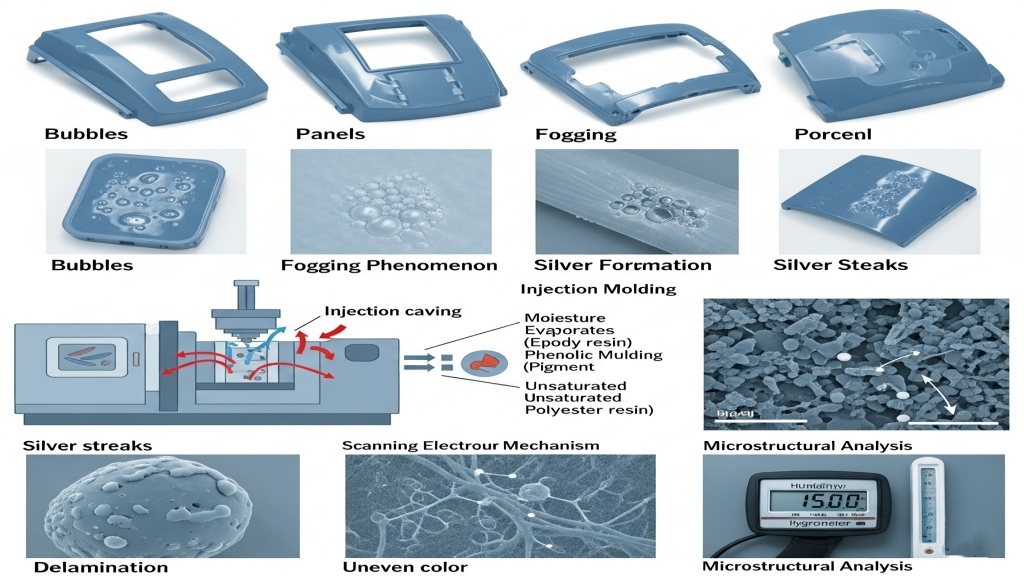

What surface defects can moisture cause?

Moisture evaporates during molding under high temperatures, often leading to bubbles, fogging, or silver streaks on the surface of molded parts. Surface defects directly impact perceived quality and market positioning.

- Surface bubbling: Trapped steam disrupts proper molding.

- Uneven color: Moisture affects pigment dispersion.

- Silver streaks: Caused by vapor trails under surface tension.

- Surface delamination: Steam pressure separates layers, weakening structure.

How to reduce moisture risks in thermosets?

Use of pre-drying, environmental controls, and optimized mold venting can reduce moisture-related issues. Material modifications can further improve resistance. Buyers should assess moisture behavior early in design to prevent future failure.

- Drying process optimization: See drying guide to maintain safe moisture levels.

- Improved mold venting: Enables effective vapor escape.

- Modified material selection: Add fillers to reduce absorption.

- Molding condition adjustments: Adjust temperature/pressure to match moisture.

Moisture Comparison Among Thermoset Materials

|

Material Type |

Moisture Rate |

Dimensional Stability |

Molding Difficulty |

Cost Control |

Surface Defect Risk |

Precision Suitability |

Modification Potential |

| Phenolic Resin | Medium | Fair | Medium | High | Medium | Average | High |

| Unsaturated Polyester | High | Poor | Medium | Medium | High | Poor | Medium |

| Melamine Resin | Low | Good | High | Medium | Low | High | Medium |

| Epoxy Resin | Medium | Good | High | Low | Medium | Medium | High |

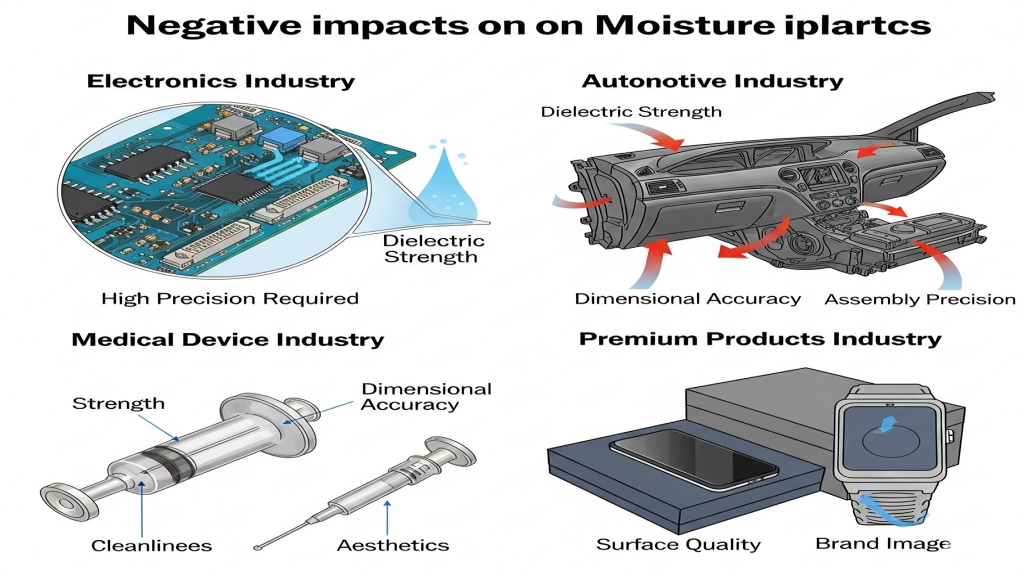

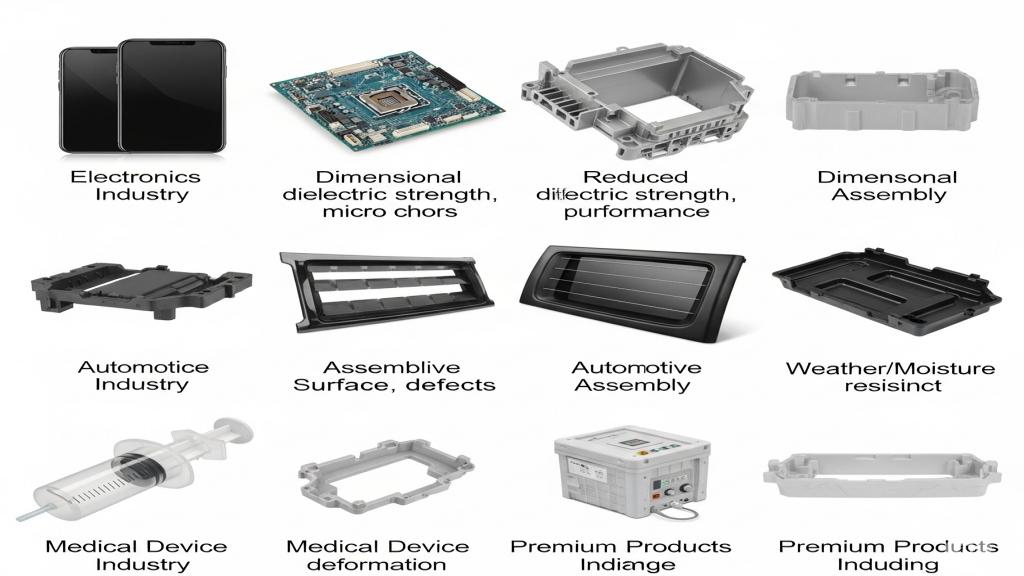

Which industries are most affected?

Moisture in molded parts most severely impacts electronics, automotive, and medical fields, where precision and surface quality are critical. The higher the product tier, the more demanding the moisture performance.

1.Electronics: Tight tolerances and dielectric strength required.

2.Automotive: Dimensional shift affects assembly precision.

3.Medical devices: Demands strength, cleanliness, and aesthetics.

4.Premium products: Surface flaws harm brand image.

Conclusion

Moisture absorption in thermoset plastics affects dimensional accuracy, surface quality, and processing consistency. Material selection, mold design, and application environment must all be considered systematically. For high-value precision components, moisture behavior should be evaluated from the earliest design stages.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: May-30-2025