Introduction

In brass CNC machining, accurate quotations not only help save costs but also accelerate project progress. Only when sufficient information is provided can suppliers give realistic and tailored prices. This reflects the efficiency of communication and directly impacts production decisions.

Complete design data and clear process requirements are the foundation of accurate quotations. By offering comprehensive details in the early stage, companies minimize repeated communication and increase project feasibility. This enables purchasing and production teams to collaborate efficiently on the same level.

What Design Data Improves Quotation Accuracy?

In brass CNC machining, the completeness of design data directly determines the precision of the quotation. If dimensions or 3D drawings are missing, the quotation often becomes inaccurate. Providing full CAD data and technical specifications avoids repeated revisions and hidden costs.

- Complete Drawings: Ensure suppliers fully understand the structure.

- [Dimensional Tolerances](- **Surface Finishes: Such as polishing or plating, avoiding overlooked processes.)**: Clarify critical precision requirements.

- Material Specifications: Confirm brass grade and performance needs.

- Surface Finishes: Such as polishing or plating, avoiding overlooked processes.

Detailed design data is the foundation of accurate quotations.

How Do Process Requirements Affect Final Quotes?

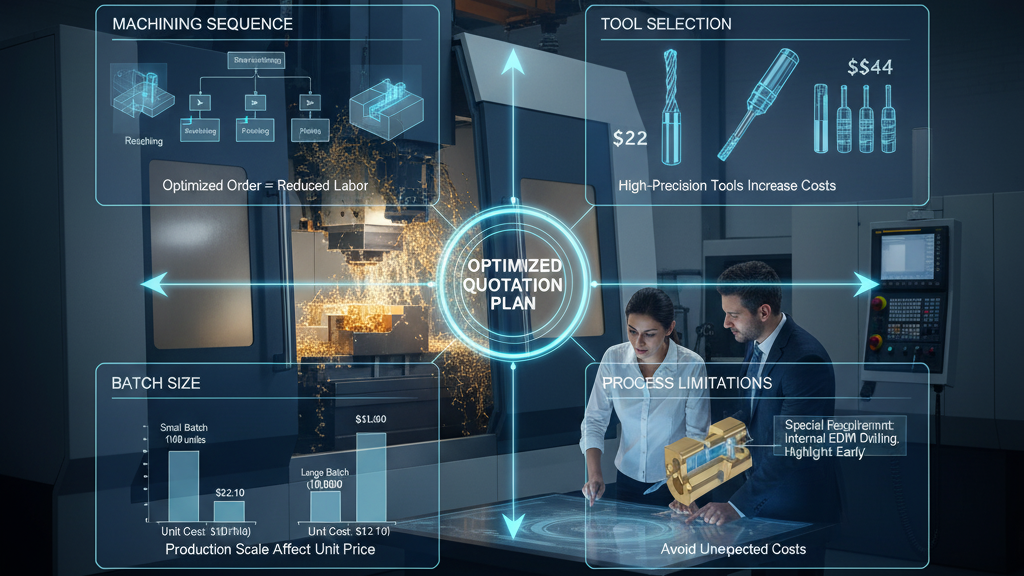

In brass CNC machining, different process details significantly impact pricing. For example, machining sequence, tool selection, and complexity add extra costs. By defining process paths clearly, suppliers can better estimate time and expenses.

- Machining Sequence: Optimized order reduces labor hours.

- Tool Selection: High-precision tools may increase costs.

- Batch Size: Production scale affects unit price.

- Process Limitations: Special requirements should be highlighted early.

Clear process requirements help suppliers optimize quotation plans.

What Additional Information Reduces Communication Costs?

At the early stage of projects, if customers provide application context and delivery timelines, suppliers can develop efficient production plans. Such information not only improves quotation accuracy but also avoids repeated confirmations later.

- Delivery Schedule: Influences planning and rush order fees.

- Application Scenarios: Helps select the right machining strategy.

- Inspection Standards: Ensures compliance with industry or customer criteria.

- Packaging & Logistics: Prevents unnecessary transport costs.

Additional information reduces unnecessary communication steps.

Comparison of Quotation Elements

|

Quotation Factor |

Complete Info |

Missing Info |

Cost Impact |

Time Impact |

| Design Data | Accurate quote | Multiple revisions | Cost controlled | Faster progress |

| Process Details | Optimized plan | Vague solution | Transparent cost | On-time delivery |

| Additional Info | Smooth communication | Repeated checks | Cost optimized | Avoid delays |

| Batch Size | Lower unit price | Higher unit price | Reasonable cost | Stable schedule |

Expansion

In brass CNC machining, transparency in information impacts not only pricing but also supply chain efficiency. The more detailed the data provided upfront, the stronger the supplier’s advantage in quality and lead time. This forms the cornerstone of a stable business relationship.

1.Supply Chain Optimization: Comprehensive data enables better collaboration.

2.Cost Control: Hidden charges are avoided, and budgets stay clear.

3.Lead Time Assurance: Complete info minimizes risk of delays.

4.Long-Term Partnership: Transparent communication builds trust.

Conclusion

The accuracy of brass CNC quotations ultimately depends on whether customers can provide complete and transparent information at the start. Only when data, process requirements, and additional needs are clarified can the quotation truly reflect reality. For companies, this is not just cost management, but also a vital driver of efficient production and long-term cooperation.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-04-2025