Introduction

Flame-retardant nylons are widely used in electronics, electrical, and automotive injection parts. The grade standard determines how materials behave when exposed to fire. V0, V1, and V2 are not just levels but represent distinct performance and applicability differences.

These grades are based on the UL94 standard, indicating how the material self-extinguishes and whether it drips flaming particles. Understanding the grade difference is fundamental to material selection and product design.

What are the exact differences between V0, V1, and V2?

In injection molding, V0 is often the preferred target, but V1 and V2 have their own value depending on cost and requirements. Choosing the right grade helps balance product performance with budget concerns.

- UL94 Classification Explained: The UL94 standard defines how nylons perform under flame.

- Dripping Behavior: V0 materials cannot ignite cotton with flaming drips.

- Burning Time: V0 has the shortest allowable single burn duration of ≤10 seconds.

- Material Selection: High-spec equipment typically opts for V0-grade nylon.

Higher FR grade means stronger self-extinguishing ability, crucial for high-safety injection applications.

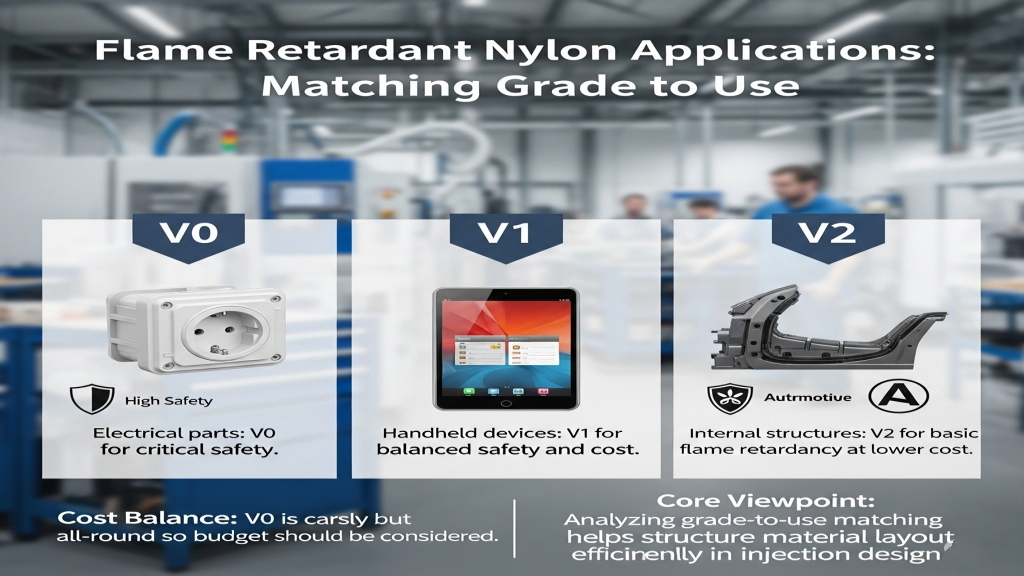

How Are Different FR Nylon Grades Used in Injection Molding?

Each FR nylon grade fits different application scenarios based on its performance. Incorrect grade selection in structural, electrical, or appliance housings may cause serious safety issues.

Injection Enclosure Solution: Electrical parts usually prefer V0-grade nylons.

V1 Applications: Suitable for medium safety applications, like handheld device housings.

V2 Grade: Better for internal structural or low-risk short-term parts.

Cost Balance: V0 is costly but all-round, so budget should be considered.

Analyzing grade-to-use matching helps structure material layout efficiently in injection design.

How to Control Cost While Ensuring Performance?

Material selection shouldn’t blindly pursue the highest grade. Designers must consider function, compliance, and volume production. Over-engineering can lead to waste and higher cost.

- Cost Control Guide: Lower cost doesn’t mean lower safety.

- Reasonable Downgrade: V1 or V2 may offer economic advantages within safety limits.

- Blended Use: Combining high and low grades can optimize assembly cost.

- Mass Production: Medium FR grades are ideal for large-volume injection.

Cost control lies in understanding application logic behind each grade—not blindly pursuing the highest.

Injection Properties Comparison of Nylon Flame-Retardant Grades

|

Item |

V0 Nylon |

V1 Nylon |

V2 Nylon |

Standard PA |

| Self-Extinguish | ≤10s | ≤30s | ≤30s | Not required |

| Dripping | Won’t ignite cotton | Won’t ignite cotton | May ignite cotton | Likely to ignite |

| Cost | High | Medium | Low | Lowest |

| Molding Stability | Good | Moderate | Poor | No FR function |

| Application | Electrical, Premium | Medium-load parts | Internal structures | Structural only |

Extension

Flame-retardant grades impact not only fire resistance but also regulatory design. The material formulas affect decomposition and mold wear during processing. A deeper understanding of FR grades enhances your product’s professionalism and marketability.

1.Designing material layout improves both safety and cost outcomes.

2.Advising clients on proper FR levels reduces post-sale risk.

3.Integrating standards into early R&D accelerates time to market.

4.Offering products across FR levels creates tiered pricing strategies.

Conclusion

V0, V1, and V2 grades reflect a trade-off among flame resistance, self-extinguishing ability, and safety across applications. Mastering these grade differences is key for any injection developer. Smart selection isn’t about always choosing the top—it’s about matching usage and economy. With regulations tightening, flame-retardant ratings will increasingly become a baseline expectation.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Jul-31-2025