Introduction

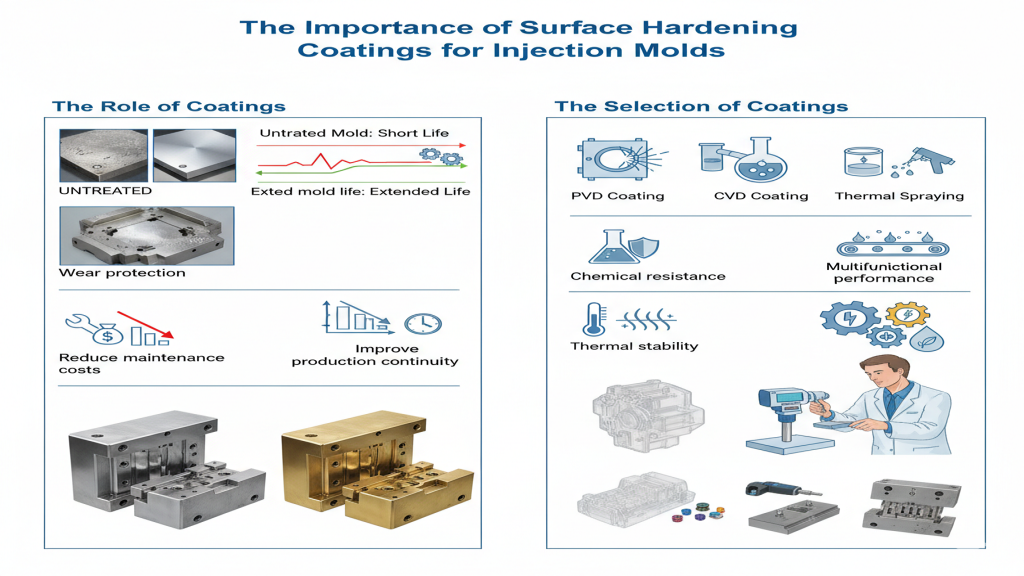

In the injection molding industry, surface hardening coatings are not only a form of wear protection but also a key process for extending mold life. High-quality coatings can significantly reduce maintenance costs and improve production continuity.

As the demand for product precision and aesthetics grows, the choice of coating technology has expanded from simple protection to include chemical resistance, heat stability, and multifunctional performance. The right coating process not only enhances surface hardness but also boosts the market competitiveness of molded parts.

Which coating maximizes hardness?

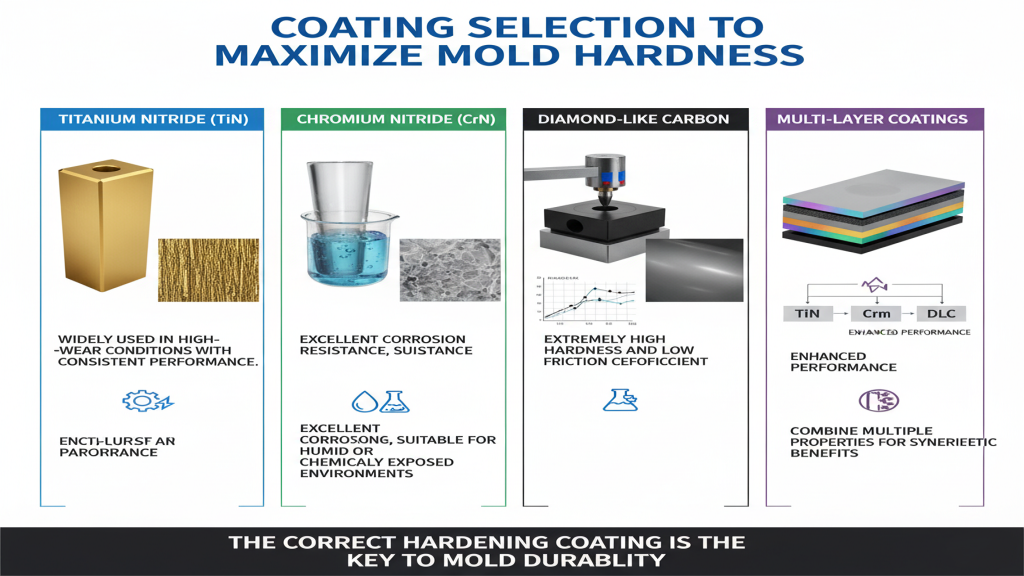

In injection molds, hardness improvement is a critical factor for extending service life. With the right coating, molds can maintain stable performance under heavy load conditions.Different coating materials such as Titanium Nitride, Chromium Nitride, and Diamond-Like Carbon perform differently in terms of wear resistance and impact resistance, requiring precise application matching.

- Titanium Nitride (TiN): Widely used in high-wear conditions with consistent performance.

- Chromium Nitride (CrN): Excellent corrosion resistance, suitable for humid or chemically exposed environments.

- Diamond-Like Carbon (DLC): Extremely high hardness with low friction coefficient.

- Multi-layer coatings: Combine multiple properties for synergistic benefits.

The right hardening coating is the key to mold durability

Which coating enhances the product appearance?

Appearance is not only a reflection of product quality but also a driver of customer perception. Coatings can provide gloss, uniformity, and scratch resistance to injection parts.Common processes like PVD and DLC enhance surface aesthetics while maintaining long-term durability.

- PVD Physical Vapor Deposition: Provides premium gloss and stable colors.

- DLC Diamond-Like Coating: Mirror-like finish, ideal for transparent or glossy parts.

- Titanium Nitride (TiN): Creates a metallic appearance, widely used for visible components.

- Spray + Hardening Combo: Balances aesthetics and durability at a cost-effective level.

Aesthetic coatings make injection molded products more attractive in the market

Which coating is suitable for high-temperature conditions?

Under high-temperature conditions, mold coatings must maintain a balance between hardness and chemical resistance. Thermal stability is the key to preventing mold failure.In engineering plastics and specialty resin molding, choosing the right high-temperature coating directly impacts mold reliability.

- Chromium Nitride (CrN): Maintains stability under elevated temperatures.

- Aluminum Titanium Nitride (AlTiN): Outstanding oxidation resistance, ideal for high-heat friction.

- DLC Coating: Retains low friction properties under moderate heat.

- Multi-layer coatings: Combine thermal resistance with wear performance.

High-temperature resistant coatings ensure stable mold production

Surface Hardening Coating Comparison

|

Coating Type |

Hardness |

Wear Resistance |

Appearance |

Heat Resistance |

| TiN | High | High | Metallic Gloss | Average |

| CrN | Medium | High | Moderate | Excellent |

| DLC | Very High | Very High | Mirror Finish | Moderate |

| AlTiN | High | High | Dark Tone | Excellent |

Looking for the best coating solution for your molds? Don’t hesitate to contact us

The Industrial Value of Coating Selection

Surface hardening coatings are not just about process improvement but also about upgrading industrial capability. They help companies maintain technical advantages in highly competitive markets.With the growing demand for eco-friendly and energy-efficient solutions, coating choices are moving toward sustainable and efficient options.

1.Cost Advantage: Reduce mold maintenance and replacement frequency.

2.Market Competitiveness: Improve product appearance and lifespan to win customer trust.

3.Production Efficiency: Minimize downtime and ensure reliable delivery.

4.Technology Forward: Keep pace with new polymer material developments.

Conclusion

Coating technology is a cornerstone of mold optimization in injection molding, and the choice of process determines overall performance in hardness, aesthetics, and heat resistance. The right coating not only improves performance but also lowers long-term costs.Amid growing market competition, companies should align product positioning with process requirements to choose the most valuable coating path. In the future, with new materials and eco-friendly technologies, coatings will become a hidden weapon for businesses to win the market.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-24-2025