Introduction

Polyphenylene Oxide (PPO) is widely used in injection molding due to its outstanding hydrolysis resistance. It remains stable even in humid and high-temperature environments, avoiding performance loss caused by hydrolytic degradation. In automotive, electrical, and medical industries, this property of PPO directly affects product lifespan and reliability.

As demand for high-performance plastics continues to rise, PPO’s hydrolysis resistance has become a decisive factor in its competitiveness. It not only reduces long-term maintenance costs but also helps manufacturers build market trust. Therefore, choosing PPO injection parts with excellent hydrolysis resistance is vital for modern manufacturing.

Why does hydrolysis resistance affect PPO’s performance in injection molding?

When exposed to moisture or high temperatures after molding, PPO can suffer from chain scission due to water penetration. This phenomenon severely reduces the strength and dimensional stability of the part, lowering overall reliability. Hence, hydrolysis resistance must be a priority in design to ensure long-term performance.

- Molecular structure optimization: Improve hydrolysis resistance through material design.

- Processing control: Proper molding reduces internal stress.

- Stabilizer additives: Enhance PPO’s resistance to humid conditions.

- Application testing: Verify long-term stability under high humidity.

Hydrolysis resistance directly determines the long-term stability of PPO molded parts

How does hydrolysis resistance improve PPO’s reliability in applications?

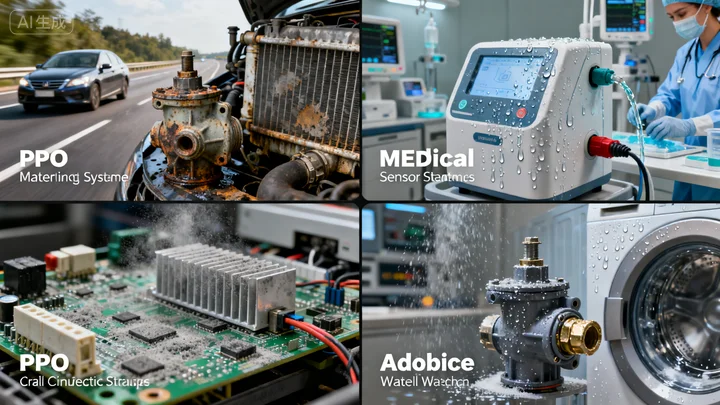

PPO often faces environmental challenges such as temperature fluctuations and humidity exposure. PPO with strong hydrolysis resistance maintains high strength and low deformation even after long-term use. This is critical for automotive components, electronic housings, and other applications that require high reliability.

- Automotive industry: PPO ensures durability in cooling system parts.

- Medical devices: Stable in humid or sterilization environments.

- Electronics: PPO housings retain insulation and strength.

- Home appliances: Extend product lifespan and reduce repairs.

Reliable PPO materials allow parts to perform stably in harsh environments

How does hydrolysis resistance help PPO compete in high-end markets?

High-end markets demand durability and safety from materials. PPO, with its strong hydrolysis resistance, stands out in new energy vehicles, 5G equipment, and medical consumables. By combining advanced molding processes with material modification, manufacturers can further enhance their competitiveness.

- High-end automotive parts: Longer service life, lower maintenance costs.

- 5G communication devices: Stable insulation and structure.

- Medical consumables: Reliable under humid sterilization conditions.

- Sustainable manufacturing: Long-lasting parts support environmental goals.

PPO’s hydrolysis resistance is the key to winning in high-end markets

Comparison of Hydrolysis Resistance in Materials

|

Material |

Hydrolysis Resistance |

Service Life |

Suitable Environment |

Cost Level |

| PPO | Excellent | Long-term | High humidity/heat | Medium |

| PA66 | Moderate | Average | Medium humidity/temp | Low |

| PBT | Good | Long | Mid-to-high humidity | Medium |

| PC | Poor | Short | Low humidity/temp | High |

Learn more about selecting hydrolysis-resistant PPO materials by contact us to empower your products.

Expansion

As industries evolve, manufacturers focus not only on mechanical strength but also on long-term stability under environmental exposure. PPO’s hydrolysis resistance will become an even stronger reason for companies to adopt it in the future. By partnering with professional teams, enterprises can quickly integrate this high-performance material into production.

1.Extended performance: PPO remains stable in humid environments.

2.Industrial adoption: High-end sectors will increasingly adopt PPO.

3.Eco-friendly: Longer lifespan reduces plastic waste.

4.Market advantage: Hydrolysis resistance supports product upgrades.

Conclusion

PPO’s hydrolysis resistance is not only a material advantage but also a key factor in market competitiveness. It enables products to retain strength and stability even under harsh environments. In the future, as application fields expand, PPO will continue to be a vital choice for high-performance injection molding.

For expert assistance in implementing for your production needs, visit our resource center or contact us. Let’s help you scale up your manufacturing with precision and efficiency!

Post time: Sep-28-2025