BLOG

-

Understanding Extrusion Mould: The Backbone of Modern Manufacturing

Introduction Extrusion moulding is a pivotal process in modern manufacturing, enabling the creation of continuous shapes and profiles with precision and efficiency. This blog delves into the intricacies of extrusion moulds, exploring their history, application...Read more -

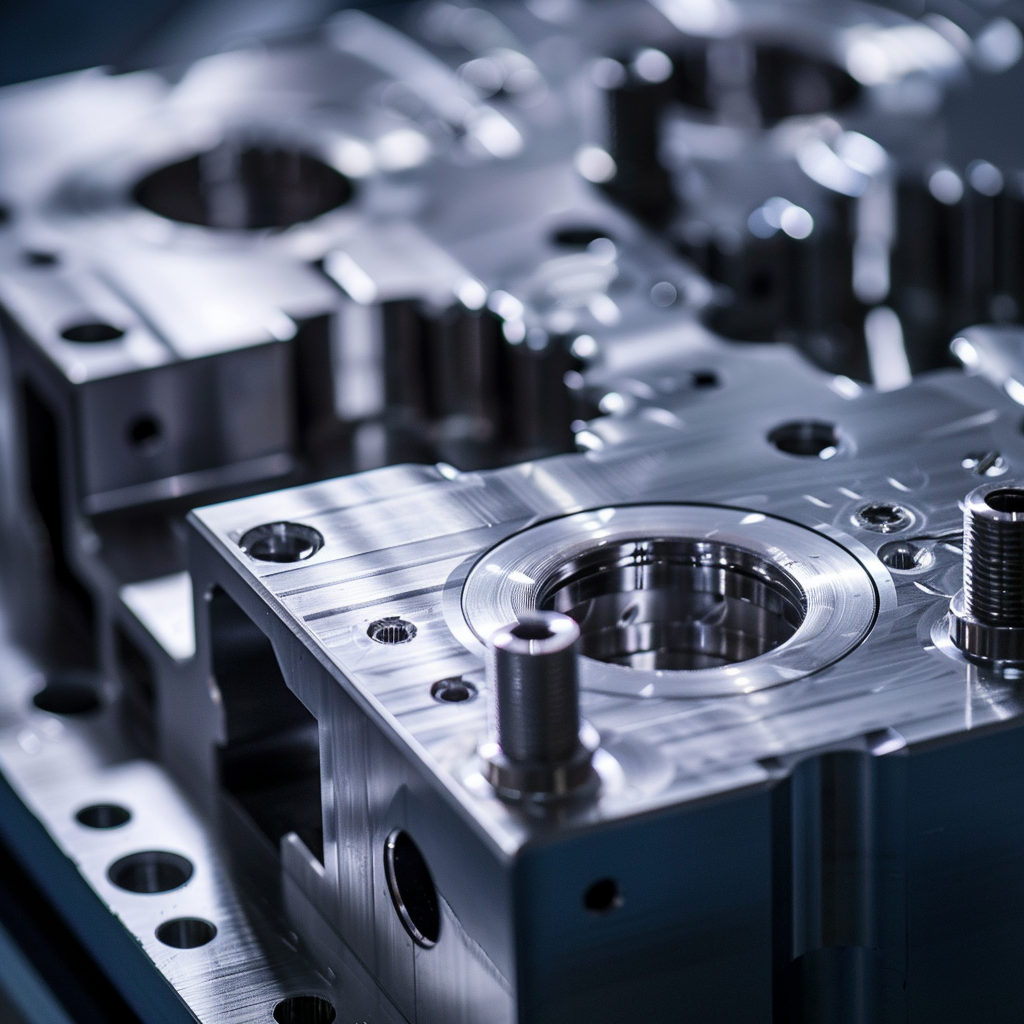

The Importance and Maintenance of Injection Molds in Manufacturing

Injection molds are crucial in the manufacturing process, especially for producing precise plastic parts. The durability and lifespan of these molds directly affect production efficiency and costs. A well-maintained mold can produce hundreds of thousands of parts, making...Read more -

The different between mater engraving and pad printing

The specifications and information of current products have become an indispensable part. Most manufacturers will engrave the information on the products through silk screen printing, pad printing or metal engraving. However, do you really understand the advantages and d...Read more -

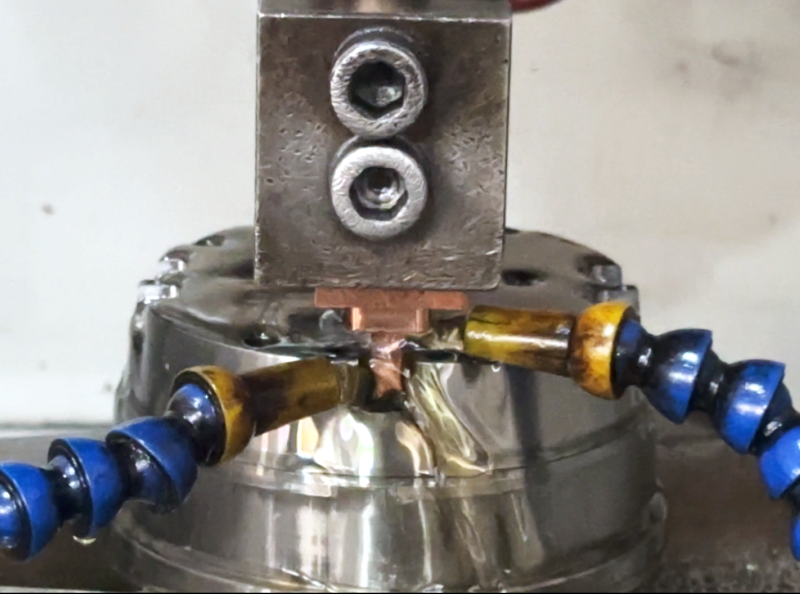

Electro spark treatment in mold processing

Today we discuss electro-spark deposition's apply in metal alloys , at the same time we will focus on this technology how to modify the mold in injection molding tooling and casting molds. What is Electro-Spark Deposition? ...Read more -

How to choose between injection molding and CNC machining

CNC and Injection as the two most be popular crafts for manufacture, which both can make the high-quality product or parts in each areas and they have their own advantages and disadvantages. So how to choose the best way for project can be a challenge. But as a professio...Read more -

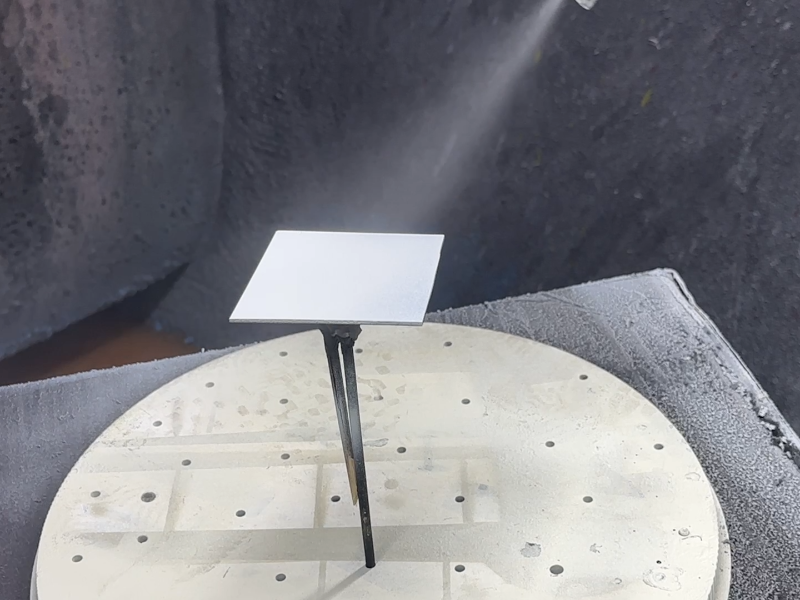

How To Make Health, Safety And clean Medical Device

When it comes to medical equipment, cleanliness, safety, is critical. All medical devices, whether disposable, implantable or reusable, must be cleaned during the manufacturing process to remove oil, grease, fingerprints and other manufacturing contaminants. Reusable pro...Read more -

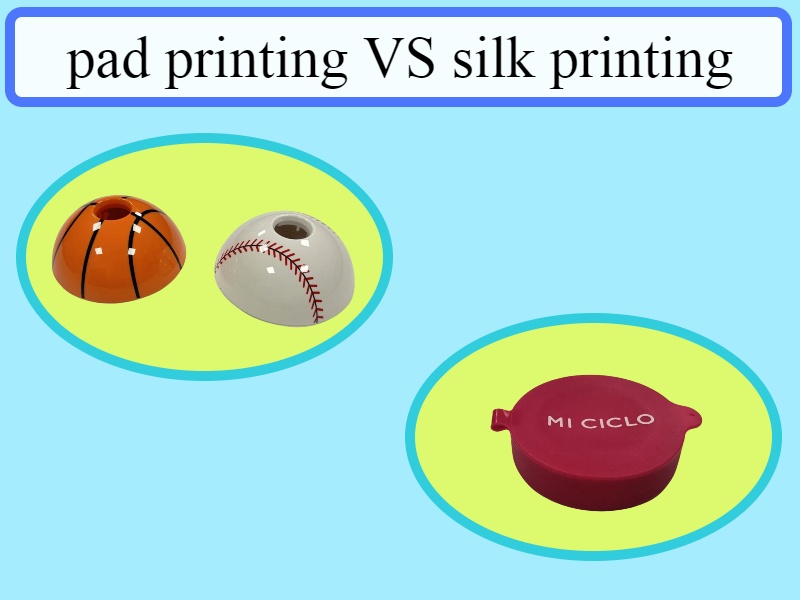

Understanding the Difference Between Pad Printing and Screen Printing

Pad printing and screen printing are two different printing methods that are used on a variety of products and on a variety of different materials. Screen printing is used on textiles, glass, metal, paper and plastic. It can be used on balloons, decals, apparel, medical ...Read more -

Silk Print in Fashion and Home Decor productv

What is silk printing? Screen printing is pressing ink through a stencil screen to create a printed design. It is a broad technology that is widely used in different industries. The process is sometimes called screen printing or screen printing, but these names essential...Read more -

The Guide to injection mold Post-Processing Methods

Post-processing enhances the properties of plastic injection molded parts and prepares them for their intended end use. This step involves corrective measures to eliminate surface defects and secondary processing for decorative and functional purposes. In the RuiCheng, p...Read more -

What is pad printing

Pad printing, also known as tampography or tampo printing, is a versatile indirect offset printing technique that utilizes a silicone pad to transfer 2-dimensional images from a laser-engraved printing plate onto 3-dimensional objects. This process enables the printing o...Read more -

Metal or Plastic: What Are the Differences?

When it comes to creating a product, the choice between plastic and metal can be a difficult one. Both materials have their unique advantages, but they also share some surprising similarities. For instance, both plastic and metal can offer heat resistance and strength, w...Read more -

Something you need to know about TPU injection molding

Tpu InjectionThere are various methods of TPU molding process: injection molding, blow molding, compression molding, extrusion molding, etc., among which injection molding is the most common. The function of injection molding is to process TPU into the required parts, which is divide...Read more