18 Years Factory Die Cast Part - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng

Product Details

18 Years Factory Die Cast Part - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng Detail:

Client’s request

1. Produce the part as per 3D file and control the accuracy within 0.05M.

2. CMM Inspection refer to the tolerance of 2D drawing.

3. Make sure the assembly is Ok.

Our Analysis

After receiving Client’s drawings and requests, our professional engineers have a the thorough analysis and confirmation that we can produce this part strictly and control all dimensions in tolerance. For making sure the assembly is OK, we requested client to provide the Assembly drawing to check there is no any interference with other components.

Start working

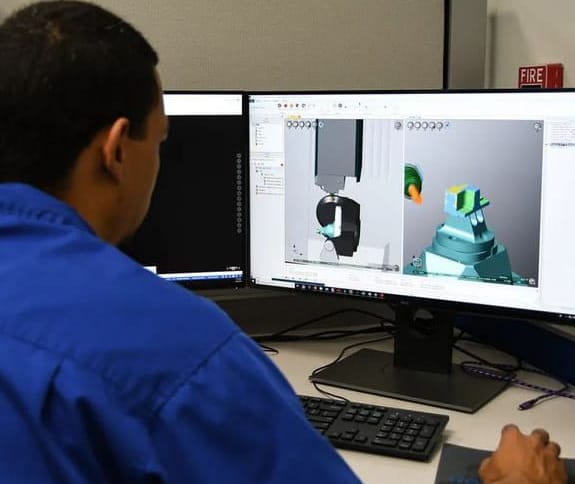

1. Programming

Our CNC programmer is working on setting the work paths of machine.

2. CNC machining

The product is being machined systematically and smoothly as per the program paths we set.

3. Hand Polished

The natural surface of products after CNC is rough and with lot of burrs and knives, Our worker now is using the sandpaper to deburr and polish the surface to have a smooth part without any sharp edges. The part will be sanded from coarse to fine sandpaper (400-1500) level grinding until the surface is smooth.

4.CMM(coordinate measuring machine) Inspection

Our QC is adjusting the CMM machine to have an accurate inspection on dimensional accuracy, positioning accuracy, geometric accuracy and contour accuracy.

5.Shipping

After our QC gave green light on this product,we will ship them out with the strong package to protect product. So that every product will be delivered in the good condition.

Product detail pictures:

Related Product Guide:

Our firm sticks on the theory of "Quality will be the life in the enterprise, and status could be the soul of it" for 18 Years Factory Die Cast Part - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng , The product will supply to all over the world, such as: Borussia Dortmund, Italy, Nigeria, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!