8 Year Exporter Die Casting Molds - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng

Product Details

8 Year Exporter Die Casting Molds - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng Detail:

Client’s request

1. Produce the part as per 3D file and control the accuracy within 0.05M.

2. CMM Inspection refer to the tolerance of 2D drawing.

3. Make sure the assembly is Ok.

Our Analysis

After receiving Client’s drawings and requests, our professional engineers have a the thorough analysis and confirmation that we can produce this part strictly and control all dimensions in tolerance. For making sure the assembly is OK, we requested client to provide the Assembly drawing to check there is no any interference with other components.

Start working

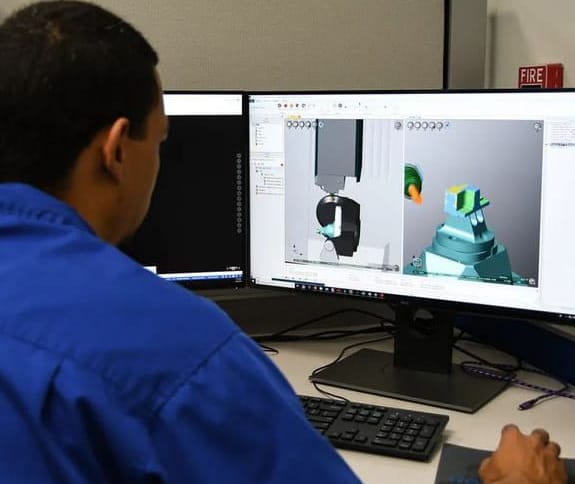

1. Programming

Our CNC programmer is working on setting the work paths of machine.

2. CNC machining

The product is being machined systematically and smoothly as per the program paths we set.

3. Hand Polished

The natural surface of products after CNC is rough and with lot of burrs and knives, Our worker now is using the sandpaper to deburr and polish the surface to have a smooth part without any sharp edges. The part will be sanded from coarse to fine sandpaper (400-1500) level grinding until the surface is smooth.

4.CMM(coordinate measuring machine) Inspection

Our QC is adjusting the CMM machine to have an accurate inspection on dimensional accuracy, positioning accuracy, geometric accuracy and contour accuracy.

5.Shipping

After our QC gave green light on this product,we will ship them out with the strong package to protect product. So that every product will be delivered in the good condition.

Product detail pictures:

Related Product Guide:

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for 8 Year Exporter Die Casting Molds - Analysis of CNC Machining Case of Aluminium Battery Shell – Ruicheng , The product will supply to all over the world, such as: Malaysia, Swansea, Oslo, We will initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.